Are you gearing up for an interview for a Fill Plant Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Fill Plant Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

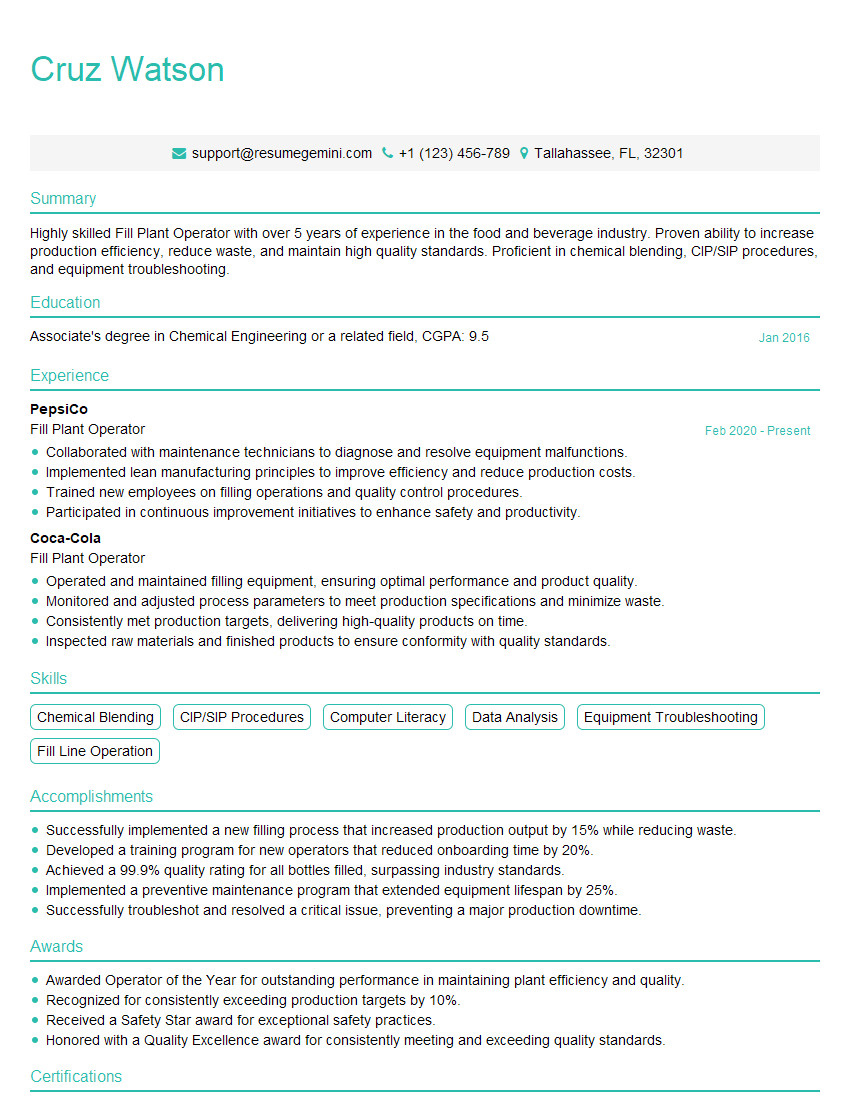

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fill Plant Operator

1. Explain the role of a Fill Plant Operator in detail?

As a Fill Plant Operator, my primary responsibility is to ensure the efficient and accurate filling of products into containers. I operate and maintain filling machines, monitoring their performance and making adjustments as needed. I also adhere to established quality control procedures, ensuring that products meet specifications and are safe for distribution.

2. Describe the types of filling equipment you have experience operating?

Rotary Fillers

- Rotary piston fillers

- Rotary gravity fillers

Inline Fillers

- Overflow fillers

- Net weight fillers

Other Fillers

- Semi-automatic fillers

- Volumetric fillers

3. What are the critical quality control parameters you monitor during the filling process?

- Fill weight or volume

- Container integrity

- Seal integrity

- Labeling accuracy

- Product temperature

4. What are some common challenges faced by Fill Plant Operators, and how do you overcome them?

Product Viscosity

- Adjusting filling rates and temperatures

- Utilizing anti-foaming agents

Foaming

- Reducing filling speeds

- Installing anti-foamers

Equipment Malfunctions

- Troubleshooting and repairing minor issues

- Reporting major issues to maintenance

5. What maintenance tasks do you typically perform on filling equipment?

- Lubrication and cleaning

- Filter and nozzle replacement

- Calibration and adjustments

6. How do you handle high-pressure filling operations?

- Wearing appropriate safety gear

- Following established safety protocols

- Inspecting equipment regularly for leaks and damage

7. Describe the safety measures you take when operating filling equipment?

- Wearing proper PPE (gloves, safety glasses, etc.)

- Following lockout/tagout procedures

- Being aware of potential hazards

8. What is your approach to maintaining a clean and sanitized work environment?

- Regularly cleaning and disinfecting equipment

- Following GMP (Good Manufacturing Practices)

- Ensuring proper waste disposal

9. How do you prioritize tasks and manage your time effectively in a fast-paced environment?

- Using a work order system

- Delegating tasks to team members

- Communicating effectively with supervisors and co-workers

10. What are your key strengths and weaknesses as a Fill Plant Operator?

Strengths

- Extensive experience in operating and maintaining filling equipment

- Strong attention to detail and quality

- Ability to work independently and as part of a team

Weaknesses

- Limited experience with certain types of filling equipment (but eager to learn)

- Sometimes I may be too perfectionistic, which can lead to delays if I’m not careful.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fill Plant Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fill Plant Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Fill Plant Operator is responsible for the safe and efficient operation of fill plant equipment, ensuring that products are filled accurately and efficiently.

1. Equipment Operation

Operate and maintain filling machines, conveyors, and other equipment used in the filling process.

- Monitor equipment performance and make adjustments as needed.

2. Product Quality

Ensure that products are filled to the correct weight or volume.

- Inspect products for defects.

- Calibrate and maintain filling equipment to ensure accuracy.

3. Production Efficiency

Maximize production output while maintaining quality standards.

- Identify and eliminate bottlenecks in the filling process.

4. Safety and Compliance

Maintain a safe work environment and comply with all applicable regulations.

- Follow safety protocols and wear appropriate safety gear.

- Report any hazards or accidents to supervisors.

Interview Tips

To ace the interview for a Fill Plant Operator position, it’s crucial to demonstrate your technical skills, attention to detail, and commitment to safety. Here are some tips to help you prepare:

1. Research the Company and Industry

Become familiar with the company’s products, operations, and industry trends. This will enable you to tailor your answers to the specific requirements of the role.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating and maintaining filling equipment, as well as your understanding of quality control and safety procedures. Quantify your accomplishments whenever possible to illustrate your impact.

3. Prepare for Technical Questions

Expect questions about your knowledge of filling equipment, calibration techniques, and troubleshooting procedures. Be prepared to discuss your understanding of how these processes contribute to product quality and efficiency.

4. Showcase Your Attention to Detail

Fill Plant Operators must be precise and meticulous in their work. Highlight your attention to detail by providing specific examples of how you have ensured product accuracy and consistency in previous roles.

5. Emphasize Safety and Compliance

Safety is paramount in fill plant operations. Demonstrating your commitment to following safety protocols and adhering to regulations will be highly valued by potential employers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fill Plant Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!