Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Filler Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Filler Machine Operator so you can tailor your answers to impress potential employers.

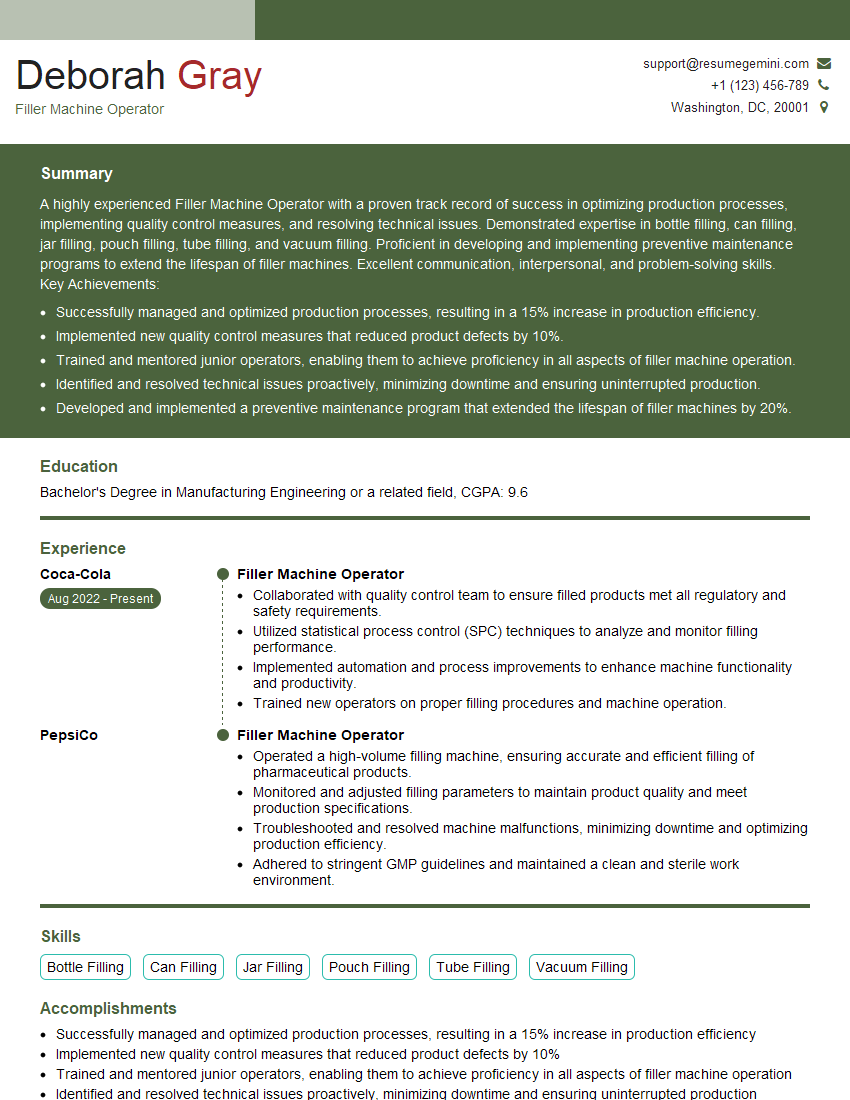

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filler Machine Operator

1. What are the different types of fillers used in the filling machine?

There are several types of fillers used in filling machines, including:

- Positive displacement fillers: These fillers use a piston or other positive displacement mechanism to accurately measure and dispense the fill volume.

- Gravity fillers: These fillers rely on gravity to fill containers, and are often used for free-flowing liquids.

- Volumetric fillers: These fillers measure the fill volume based on the volume of liquid displaced by a rotating impeller.

- Net weight fillers: These fillers weigh the containers before and after filling to ensure the target fill weight is achieved.

2. How do you calibrate a filling machine?

Zero calibration

- Run the filler without any product to establish a zero point.

- Adjust the zero point until the filler consistently dispenses the correct amount of product.

Span calibration

- Fill a container with the target fill volume.

- Adjust the span calibration until the filler consistently dispenses the target fill volume.

3. What are the common maintenance tasks required for a filling machine?

Regular maintenance is essential to ensure the optimal performance and longevity of a filling machine. Some common maintenance tasks include:

- Cleaning and sanitizing the machine to prevent contamination.

- Inspecting and replacing worn or damaged parts, such as seals, gaskets, and filters.

- Lubricating moving parts to minimize friction and wear.

- Calibrating the machine to ensure accurate filling.

4. How do you troubleshoot a filling machine that is not filling accurately?

Troubleshooting a filling machine that is not filling accurately requires a systematic approach:

- Verify that the machine is properly calibrated.

- Check for any blockages or leaks in the product supply line.

- Inspect the filling nozzles and ensure they are not clogged or damaged.

- Examine the container being filled for any defects or variations that could affect the fill volume.

- Check the machine’s settings and ensure they are appropriate for the product being filled.

5. What are the safety precautions that should be followed when operating a filling machine?

Operating a filling machine safely is paramount to prevent accidents and injuries:

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Ensure that the machine is properly grounded to prevent electrical hazards.

- Never attempt to clear a jam or blockage while the machine is running.

- Be aware of the location of emergency stop buttons and know how to use them.

- Follow all manufacturer’s instructions for safe operation and maintenance.

6. How do you ensure that the filled containers meet the required quality standards?

Ensuring the quality of filled containers involves several key practices:

- Regularly inspect the containers for any defects or damage.

- Monitor the fill volume and ensure it consistently meets the target specifications.

- Check the seal integrity of the containers to prevent leaks or contamination.

- Implement quality control procedures to identify and remove any non-conforming containers.

7. What are the different types of filling heads used in filling machines?

Filling heads play a crucial role in the filling process, and there are several types commonly used:

- Nozzle filling heads: These heads use nozzles to dispense the product into containers.

- Overflow filling heads: These heads fill containers by overflowing the product into them.

- Volumetric filling heads: These heads measure the fill volume and dispense the product accordingly.

- Net weight filling heads: These heads weigh the containers before and after filling to achieve the target fill weight.

8. How do you handle different types of products with varying viscosities on a filling machine?

Handling different product viscosities requires adjustments to the filling machine:

- For low-viscosity products, use filling heads with smaller nozzles and higher flow rates.

- For high-viscosity products, use filling heads with larger nozzles and slower flow rates.

- Adjust the filling speed and pressure to optimize the flow of the product.

- Consider using heated filling systems for viscous products to improve their flowability.

9. What are the factors that can affect the accuracy of a filling machine?

Several factors can influence the accuracy of a filling machine:

- Calibration errors

- Variations in product viscosity

- Container size and shape

- Environmental factors (e.g., temperature, humidity)

- Machine wear and tear

10. How do you maintain a clean and sanitary filling environment?

Maintaining a clean and sanitary filling environment is essential for product quality and safety:

- Regularly clean and sanitize all equipment and surfaces that come into contact with the product.

- Implement good manufacturing practices (GMPs) to prevent contamination.

- Train operators on proper hygiene and sanitation procedures.

- Use appropriate cleaning and sanitizing agents that are compatible with the products and equipment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filler Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filler Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Filler Machine Operators play a pivotal role in packaging industries, ensuring accuracy and efficiency in filling containers with various liquid or semi-liquid substances. Here are the key job responsibilities:

1. Machine Operation and Maintenance

Operate and monitor filling machines, adjusting settings and parameters to ensure optimal performance.

- Monitor machine operation and identify any potential issues promptly.

- Perform routine maintenance tasks, such as cleaning and lubrication, to keep the machine in good working order.

2. Quality Control

Inspect filled containers for accuracy, ensuring that they meet specified weights, volumes, and quality standards.

- Take samples of filled containers and test them to verify product quality and compliance.

- Adjust machine settings as needed to minimize errors and maintain product consistency.

3. Production Monitoring

Monitor production output and maintain records of filled containers, including quantities, batch numbers, and product specifications.

- Identify and address any production bottlenecks or inefficiencies.

- Coordinate with other production team members to ensure smooth and efficient workflow.

4. Safety and Compliance

Adhere to all safety protocols and regulations related to machine operation and handling of hazardous materials.

- Wear appropriate safety gear and follow established safety procedures.

- Ensure that the work area is clean and organized to minimize risks.

Interview Tips

To ace the interview for a Filler Machine Operator position, consider the following preparation tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, industry, and culture. Research the specific role and the company’s expectations for the position.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating filling machines, maintaining equipment, and ensuring product quality. Showcase your understanding of industry standards and safety protocols.

3. Prepare for Technical Questions

Anticipate technical questions related to machine operation, troubleshooting, and quality control procedures. Be prepared to discuss your knowledge of different types of filling machines and their applications.

4. Showcase Problem-solving Abilities

Share examples of how you have resolved production issues, improved efficiency, or ensured product quality in previous roles. Highlight your problem-solving skills and ability to work independently.

5. Practice Behavioral Interview Questions

Prepare for behavioral interview questions that focus on teamwork, communication, and attention to detail. Provide specific examples that demonstrate your strengths in these areas.

6. Ask Thoughtful Questions

During the interview, ask thoughtful questions that demonstrate your interest in the company and the role. This shows that you are engaged and eager to learn more.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Filler Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.