Are you gearing up for an interview for a Filler Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Filler Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

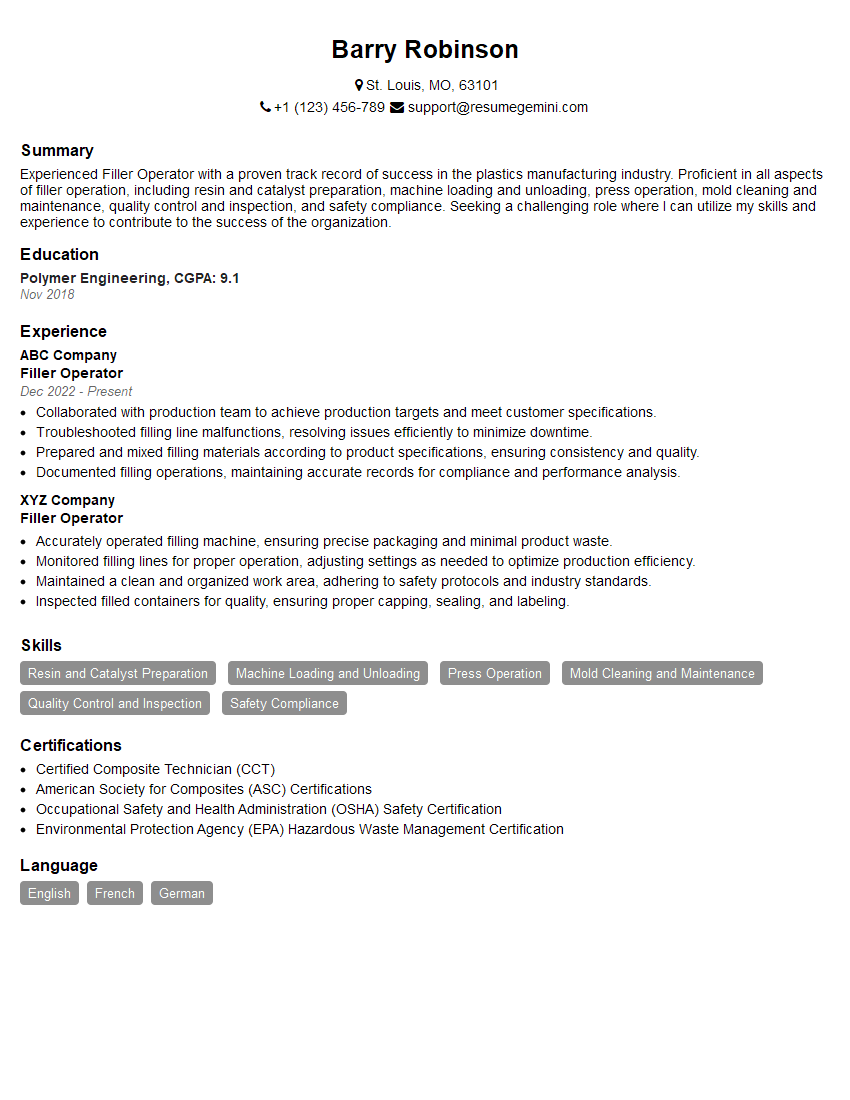

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filler Operator

1. What are the different types of fillers used in the manufacturing process?

There are various types of fillers used in the manufacturing process, including:

- Inert fillers: These fillers do not react chemically with the resin system and are used to reduce cost, improve processing, and enhance certain properties.

- Reinforcing fillers: These fillers improve the mechanical properties of the composite, such as strength, stiffness, and toughness.

- Functional fillers: These fillers impart specific properties to the composite, such as electrical conductivity, thermal conductivity, or flame retardancy.

2. How do you determine the optimal filler loading for a specific application?

Factors to Consider:

- Desired mechanical properties

- Processing requirements

- Cost constraints

Optimization Process:

- Start with a low filler loading and gradually increase it.

- Test the composite’s properties at each filler loading.

- Determine the filler loading that provides the best balance of properties for the specific application.

3. What are the common methods used to mix fillers with resin systems?

Common methods for mixing fillers with resin systems include:

- Hand mixing: Suitable for small batches and low viscosity resin systems.

- Mechanical mixing: Uses a mixer to achieve a homogeneous mixture, suitable for larger batches and higher viscosity resin systems.

- Sonication: Utilizes ultrasonic waves to disperse fillers evenly, particularly effective for nano-sized fillers.

4. How do you ensure the proper dispersion of fillers in the resin matrix?

Proper dispersion of fillers in the resin matrix is crucial to achieve optimal composite properties. Techniques to ensure proper dispersion include:

- Using high-shear mixing equipment

- Optimizing filler particle size and shape

- Applying surface treatments to fillers to enhance compatibility with the resin system

- Controlling mixing time and temperature

5. What are the potential challenges associated with using fillers in composites?

Challenges associated with using fillers in composites include:

- Filler agglomeration: Fillers can tend to form clumps, which can compromise composite properties.

- Filler-matrix interaction: Poor interaction between fillers and the resin matrix can lead to weak interfacial bonding and reduced composite strength.

- Processing difficulties: High filler loadings can increase the viscosity of the resin system, making processing more challenging.

6. How do you troubleshoot common problems encountered during the filler addition process?

Common problems encountered during the filler addition process and their troubleshooting steps include:

- Filler agglomeration: Use high-shear mixing, adjust filler particle size, or apply surface treatments.

- Poor filler-matrix interaction: Optimize filler surface treatment, modify the resin system, or use compatibilizers.

- Increased viscosity: Adjust filler loading, use higher shear forces during mixing, or consider using a different resin system.

7. What are the safety precautions that must be observed when handling fillers?

Safety precautions for handling fillers involve:

- Wearing appropriate personal protective equipment (PPE), including gloves, masks, and eye protection.

- Ensuring adequate ventilation to prevent inhalation of dust.

- Storing fillers in a dry and well-ventilated area to prevent moisture absorption.

- Following proper disposal procedures to minimize environmental impact.

8. How do you stay updated with the latest advancements in filler technology?

To stay updated with the latest advancements in filler technology, I engage in the following practices:

- Attending industry conferences and webinars

- Reading technical journals and research papers

- Networking with experts in the field

- Exploring online resources and databases

9. What are the key performance indicators (KPIs) used to evaluate the effectiveness of filler addition?

KPIs used to evaluate the effectiveness of filler addition include:

- Mechanical properties (e.g., tensile strength, flexural modulus, impact resistance)

- Thermal properties (e.g., thermal conductivity, heat deflection temperature)

- Electrical properties (e.g., electrical conductivity, dielectric constant)

- Processing characteristics (e.g., viscosity, moldability)

10. How do you optimize filler addition to achieve specific composite properties?

To optimize filler addition for specific composite properties, I consider:

- Type and characteristics of the filler

- Filler loading level

- Filler dispersion and interaction with the resin matrix

- Processing conditions

- Target composite properties

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filler Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filler Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Filler Operators are responsible for loading, operating, supervising, and monitoring equipment that fills containers with products. They work in a variety of industries, including food, beverage, chemical, and cosmetics. Filler Operators must have a strong understanding of the machinery they operate. They also need to be able to work independently and as part of a team, and they must pay attention to detail. Filler Operators typically report to production supervisors or plant managers.

1. Preparing and loading equipment

Filler Operators must prepare and load equipment before it can be used. This includes checking to make sure that the equipment is clean and free of debris, and loading the equipment with the correct product. Filler Operators must also make sure that the equipment is properly adjusted.

- Inspecting equipment for cleanliness and functionality

- Loading equipment with product

- Adjusting equipment settings

2. Operating equipment

Filler Operators are responsible for operating equipment according to written job procedures. This includes starting and stopping the equipment, and monitoring the equipment’s performance. Filler Operators must be able to make adjustments to the equipment as needed to ensure that the product is being filled according to specifications.

- Starting and stopping equipment

- Monitoring equipment performance

- Making adjustments to equipment

3. Troubleshooting problems

Filler Operators are responsible for troubleshooting any problems that arise with the equipment they operate. This includes identifying the source of the problem, and taking steps to resolve the problem. Filler Operators may also need to call for assistance from maintenance personnel if the problem cannot be resolved.

- Identifying the source of a problem

- Taking steps to resolve the problem

- Calling for assistance from maintenance personnel

4. Maintaining equipment

Filler Operators are responsible for maintaining the equipment they operate. This includes cleaning the equipment, lubricating the equipment, and making minor repairs. Filler Operators must also keep records of all maintenance performed on the equipment.

- Cleaning equipment

- Lubricating equipment

- Making minor repairs

- Keeping records of all maintenance performed on equipment

Interview Tips

The key to acing any interview is to prepare thoroughly in advance. Imagine you are interviewing for a position as a Filler Operator. Prepare well and do some research about the following points to showcase your knowledge and readiness for the job.

1. Knowledge of filling equipment

Interviewers will want to know that you have a strong understanding of the filling equipment you will be operating. Be prepared to discuss your experience with different types of filling equipment, and your knowledge of the principles of filling. You should also be able to discuss your experience with troubleshooting and maintaining filling equipment.

- Research different types of filling equipment

- Learn about the principles of filling

- Practice troubleshooting and maintaining filling equipment

2. Safety procedures

Safety is paramount in any industrial setting. Interviewers will want to know that you are familiar with the safety procedures for operating filling equipment. Be prepared to discuss your knowledge of these procedures, and your experience with following them. You should also be able to discuss your experience with identifying and mitigating hazards in the workplace.

- Review the safety procedures for operating filling equipment

- Practice following these procedures

- Identify and mitigate hazards in the workplace

3. Teamwork and communication skills

Filler Operators often work as part of a team. Interviewers will want to know that you have strong teamwork and communication skills. Be prepared to discuss your experience working in a team environment, and your ability to communicate effectively with others. You should also be able to discuss your experience with resolving conflicts and building consensus.

- Discuss your experience working in a team environment

- Demonstrate your ability to communicate effectively with others

- Describe your experience with resolving conflicts and building consensus

4. Problem-solving skills

Filler Operators often need to solve problems on the job. Interviewers will want to know that you have strong problem-solving skills. Be prepared to discuss your experience with solving problems, and your ability to think critically and creatively. You should also be able to discuss your experience with using data to make decisions.

- Discuss your experience with solving problems

- Demonstrate your ability to think critically and creatively

- Describe your experience with using data to make decisions

Next Step:

Now that you’re armed with the knowledge of Filler Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Filler Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini