Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Filler Spreader position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

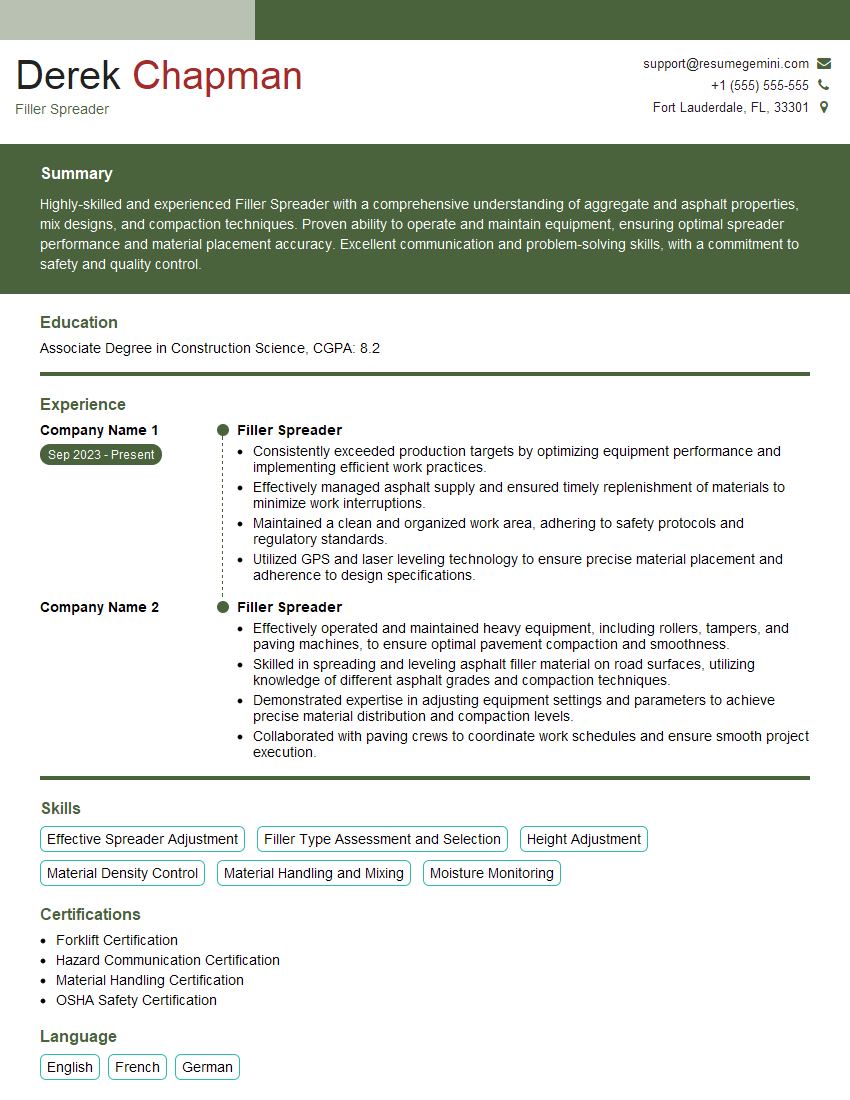

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filler Spreader

1. What are the different types of filler spreaders used in construction?

There are three main types of filler spreaders used in construction:

- Manual filler spreaders are used for small-scale projects and are operated by hand.

- Mechanical filler spreaders are used for larger projects and are powered by an engine.

- Self-propelled filler spreaders are the most advanced type of filler spreader and are used for large-scale projects. They are self-propelled and can be operated by a single person.

2. What are the factors to consider when choosing a filler spreader?

Factors to Consider:

- The size and scope of the project

- The type of material being spread

- The budget for the project

- The availability of skilled labor

Specific Considerations:

- Manual filler spreaders are best suited for small projects, such as spreading sand or gravel on a driveway.

- Mechanical filler spreaders are best suited for larger projects, such as spreading asphalt or concrete on a road.

- Self-propelled filler spreaders are best suited for large-scale projects, such as spreading fill dirt on a construction site.

3. How do you operate a filler spreader?

The operation of a filler spreader varies depending on the type of spreader. However, there are some general steps that apply to all types of spreaders:

- Prepare the material: The material should be dry and free of clumps.

- Load the material into the hopper: The hopper is the part of the spreader that holds the material.

- Set the spreader settings: The spreader settings will determine the width and thickness of the spread material.

- Operate the spreader: The spreader can be operated by hand, by an engine, or by a self-propelled motor.

- Monitor the spread material: The spread material should be monitored to ensure that it is being spread evenly and to the desired thickness.

4. What are the safety precautions that should be taken when operating a filler spreader?

There are several safety precautions that should be taken when operating a filler spreader:

- Wear appropriate safety gear: This includes a hard hat, safety glasses, gloves, and earplugs.

- Be aware of your surroundings: Be aware of other workers, equipment, and obstacles in the area.

- Do not operate the spreader if you are tired or under the influence of drugs or alcohol: Operating a spreader while impaired can be dangerous.

- Follow the manufacturer’s instructions: The manufacturer’s instructions will provide specific safety guidelines for the operation of the spreader.

5. What are the common problems that can occur when operating a filler spreader?

There are several common problems that can occur when operating a filler spreader:

- The material is not spreading evenly: This can be caused by a variety of factors, such as the spreader settings, the material being spread, or the condition of the ground.

- The material is not spreading to the desired thickness: This can be caused by the spreader settings or the material being spread.

- The spreader is not working properly: This can be caused by a variety of factors, such as a mechanical failure or a problem with the engine.

6. How do you troubleshoot a filler spreader?

There are several steps that can be taken to troubleshoot a filler spreader:

- Check the spreader settings: Ensure that the spreader settings are correct for the material being spread and the desired thickness.

- Inspect the material: Ensure that the material is dry and free of clumps.

- Check the spreader for damage: Inspect the spreader for any damage that could be causing the problem.

- Refer to the manufacturer’s instructions: The manufacturer’s instructions may provide specific troubleshooting tips for the spreader.

7. What are the maintenance requirements for a filler spreader?

The maintenance requirements for a filler spreader vary depending on the type of spreader. However, there are some general maintenance tasks that apply to all types of spreaders:

- Clean the spreader after each use: This will help to prevent the buildup of material and ensure that the spreader is working properly.

- Inspect the spreader regularly: Inspect the spreader for any damage or wear and tear.

- Lubricate the spreader regularly: This will help to keep the spreader working smoothly.

- Store the spreader in a dry place: This will help to prevent rust and corrosion.

8. What are the benefits of using a filler spreader?

There are several benefits to using a filler spreader:

- Increased productivity: Filler spreaders can help to increase productivity by spreading material more quickly and evenly than manual labor.

- Improved quality: Filler spreaders can help to improve the quality of the spread material by ensuring that it is spread to the desired thickness and consistency.

- Reduced labor costs: Filler spreaders can help to reduce labor costs by eliminating the need for manual labor to spread the material.

9. What are the different applications for filler spreaders?

Filler spreaders have a variety of applications in the construction industry, including:

- Spreading sand or gravel on driveways and walkways

- Spreading asphalt or concrete on roads and parking lots

- Spreading fill dirt on construction sites

- Spreading mulch or topsoil on landscaping projects

10. What are the latest trends in filler spreader technology?

The latest trends in filler spreader technology include:

- The development of more efficient and environmentally friendly spreaders

- The integration of technology into spreaders, such as GPS and sensors

- The development of new materials for spreaders, such as lightweight and durable plastics

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filler Spreader.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filler Spreader‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Filler Spreader is primarily responsible for operating and maintaining a filler spreading machine to spread materials such as sand, gravel, topsoil, or asphalt. Other crucial responsibilities include:

1. Material Handling

Filling the spreading machine with materials by operating excavators or loaders

- Ensuring proper filling levels and material distribution

- Monitoring material consistency and quality

2. Machine Operation

Precisely spreading materials to meet project specifications

- Setting and adjusting machine settings to achieve desired spread thickness, width, and grade

- Controlling spread rate and material flow

3. Site Management

Preparing the job site for spreading operations

- Clearing and leveling the area

- Setting up markers and stakes to guide spreading

- Ensuring safe and efficient site access

4. Quality Control

Inspecting the spread materials and finished surface

- Ensuring material meets specifications and is properly compacted

- Identifying and correcting any irregularities or defects

Interview Tips

Preparing for a Filler Spreader interview requires meticulous attention to the key job responsibilities. Here are some tips to help candidates ace the interview:

1. Highlight Relevant Experience

Emphasize previous experience in operating filler spreading machinery or similar equipment. Showcase your proficiency in handling different materials and achieving precise results.

- Provide specific examples of projects where you successfully met or exceeded project specifications.

- Discuss any specialized techniques or strategies you have developed to enhance efficiency.

2. Demonstrate Technical Knowledge

Exhibit a strong understanding of filler spreading principles, machine operation, and material properties.

- Explain the different types of filler spreading machines and their applications.

- Describe the factors that influence the spread rate, thickness, and compaction of materials.

- Discuss the safety protocols and maintenance procedures related to filler spreading operations.

3. Focus on Quality and Precision

Emphasize your commitment to delivering high-quality results by adhering to project specifications and maintaining accuracy.

- Highlight your attention to detail and ability to inspect materials and surfaces for any irregularities.

- Explain your methods for ensuring proper compaction and smoothness of the spread surface.

4. Showcase Teamwork and Communication

Filler spreading often involves collaboration with other team members. Demonstrate your ability to work effectively in a team environment.

- Describe your experience in coordinating with supervisors, engineers, and other contractors.

- Highlight your communication skills and ability to convey information clearly and concisely.

- Emphasize your willingness to receive feedback and adapt to changing project conditions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Filler Spreader interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.