Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Filling Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

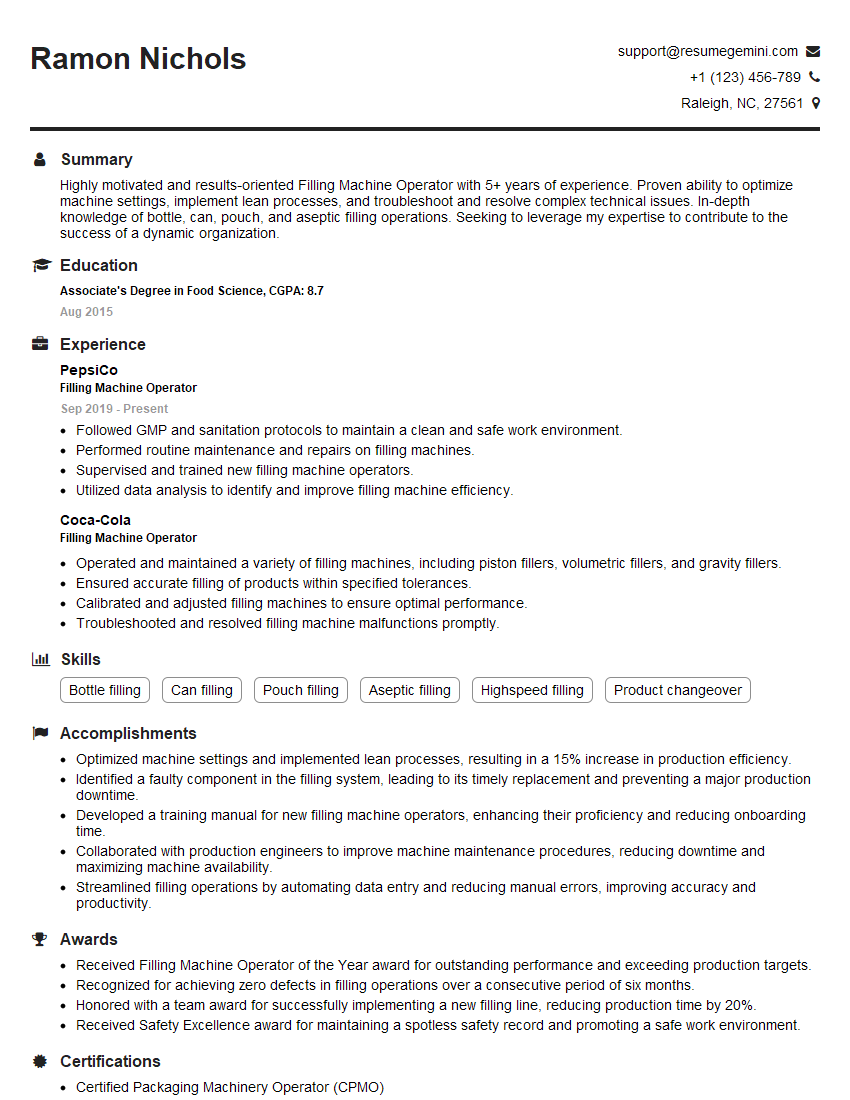

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filling Machine Operator

1. Explain the process of calibrating a filling machine?

- Start by gathering the necessary tools and materials, including a calibration weight, a set of wrenches, and a screwdriver.

- Next, remove the filling head from the machine and place it on a level surface.

- Attach the calibration weight to the filling head and then turn on the machine.

- Adjust the calibration screw until the filling head dispenses the correct amount of product.

- Once the filling head is calibrated, reattach it to the machine and run a test cycle to ensure that it is functioning properly.

2. How do you troubleshoot a filling machine that is not filling containers properly?

Check the product supply

- Ensure that the product supply is adequate and that the product is flowing properly through the filling head.

- Check for any blockages or restrictions in the product supply line.

Check the filling head

- Inspect the filling head for any damage or wear.

- Clean the filling head and make sure that all of the seals are in good condition.

- Calibrate the filling head if necessary.

Check the container

- Make sure that the container is the correct size and shape for the filling machine.

- Check for any damage or defects in the container.

- Ensure that the container is properly positioned under the filling head.

Check the machine settings

- Verify that the machine settings are correct for the product and container being used.

- Check the fill volume and speed settings.

3. What are the different types of filling machines?

- Volumetric filling machines dispense a specific volume of product into each container.

- Gravimetric filling machines measure the weight of the product being dispensed into each container.

- Positive displacement filling machines use a piston or pump to force the product into each container.

4. What are the advantages and disadvantages of using a volumetric filling machine?

Advantages

- Volumetric filling machines are relatively inexpensive to purchase and operate.

- They are easy to set up and maintain.

- They can be used to fill a wide variety of containers.

Disadvantages

- Volumetric filling machines are not as accurate as gravimetric filling machines.

- They can be affected by changes in product viscosity and temperature.

5. What are the advantages and disadvantages of using a gravimetric filling machine?

Advantages

- Gravimetric filling machines are very accurate.

- They are not affected by changes in product viscosity and temperature.

- They can be used to fill a wide variety of containers.

Disadvantages

- Gravimetric filling machines are more expensive to purchase and operate than volumetric filling machines.

- They are more difficult to set up and maintain.

6. What are the advantages and disadvantages of using a positive displacement filling machine?

Advantages

- Positive displacement filling machines are very accurate.

- They are not affected by changes in product viscosity and temperature.

- They can be used to fill a wide variety of products.

Disadvantages

- Positive displacement filling machines are more expensive to purchase and operate than other types of filling machines.

- They can be more difficult to set up and maintain.

7. What are the safety precautions that must be taken when operating a filling machine?

- Always wear appropriate safety gear, including gloves, safety glasses, and a lab coat.

- Never operate a filling machine that is not properly grounded.

- Keep the work area clean and free of clutter.

- Never reach into a filling machine while it is running.

- Always follow the manufacturer’s instructions for operating the filling machine.

8. What are the maintenance procedures that must be performed on a filling machine?

- Clean the filling head and all of the product contact surfaces on a regular basis.

- Inspect the filling head for any damage or wear.

- Lubricate the moving parts of the filling machine according to the manufacturer’s instructions.

- Calibrate the filling machine on a regular basis.

9. What are the troubleshooting tips for a filling machine that is not filling containers properly?

- Check the product supply to make sure that it is adequate and that the product is flowing properly through the filling head.

- Inspect the filling head for any damage or wear.

- Clean the filling head and make sure that all of the seals are in good condition.

- Calibrate the filling head if necessary.

- Check the container to make sure that it is the correct size and shape for the filling machine.

- Check for any damage or defects in the container.

- Ensure that the container is properly positioned under the filling head.

- Check the machine settings to make sure that they are correct for the product and container being used.

- Check the fill volume and speed settings.

10. What are the latest trends in filling machine technology?

- The use of robotics and automation to improve filling accuracy and efficiency.

- The development of new filling head designs that can handle a wider range of products.

- The integration of filling machines with other packaging equipment, such as conveyors and labelers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Filling Machine Operators work in a production environment, operating and maintaining machinery that fills containers with liquids, powders, or other substances.

1. Operating Filling Machines

Setting up and operating automatic or semi-automatic filling machines according to specified procedures

- Loading containers onto the filling line

- Monitoring the filling process and making adjustments as needed

2. Quality Control

Inspecting filled containers for accuracy, completeness, and adherence to specifications

- Testing and adjusting filling weights to ensure precise measurements

- Checking for leaks or other defects in containers

3. Machine Maintenance

Performing basic maintenance and cleaning of filling machines to ensure optimal performance

- Lubricating moving parts and performing minor repairs

- Cleaning and sanitizing machine surfaces to maintain hygiene

4. Record Keeping

Maintaining accurate records of filling operations, including production logs and quality control data

- Documenting machine settings, filling parameters, and any deviations from specifications

- Reporting any issues or downtime to supervisors

Interview Tips

Preparing well for an interview is crucial to showcase your skills and secure the job. Here are some tips to help you ace the interview for a Filling Machine Operator position:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific job you’re applying for. Learn about their products or services, industry reputation, and any relevant projects.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating and maintaining filling machines. Quantify your experience, providing specific examples of your accomplishments. Describe any industry certifications or training you have obtained.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. Anticipate questions about your ability to troubleshoot machine problems, maintain accuracy, and work effectively in a fast-paced environment.

4. Present a Positive Attitude and Enthusiasm

Convey your enthusiasm for the role and the industry. Demonstrate a positive attitude and eagerness to learn and contribute. Express your commitment to quality and attention to detail.

5. Prepare Specific Examples

Use the STAR method (Situation, Task, Action, Result) to answer interview questions. Provide specific examples that demonstrate your abilities and achievements.

For instance, when asked about your problem-solving skills, you could describe a time you identified and resolved a machine issue, resulting in increased production efficiency.

6. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive on time for the interview. Maintain good posture, make eye contact, and speak clearly and confidently.

7. Ask Questions

At the end of the interview, ask thoughtful questions to show your engagement and interest in the position. This can also provide you with additional insights into the company and the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Filling Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Filling Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.