Are you gearing up for an interview for a Filling Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Filling Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

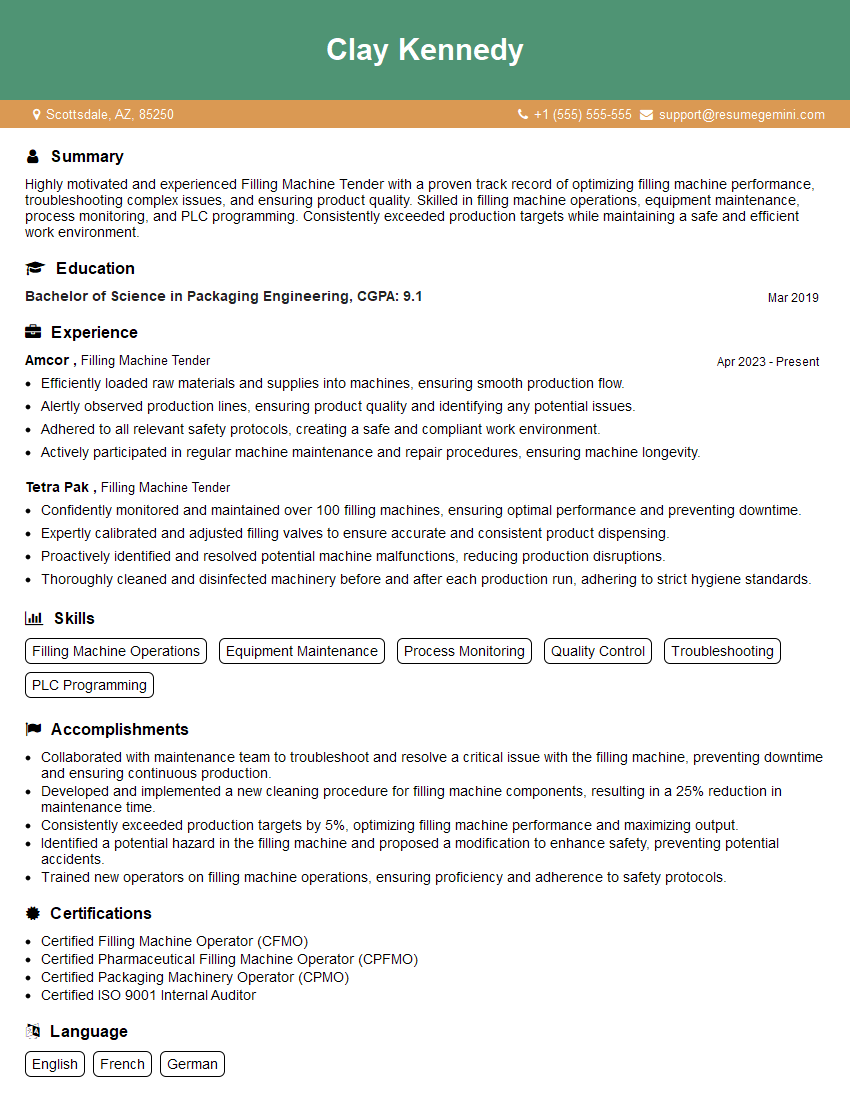

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filling Machine Tender

1. Describe the different types of filling machines you have worked with and their key features.

In my previous roles, I have experience operating a variety of filling machines, including:

- Linear filling machines: These machines are used to fill products into bottles, cans, and other rigid containers. They typically have multiple filling heads that move along a conveyor belt.

- Rotary filling machines: These machines are used to fill products into flexible containers, such as pouches and bags. They have a rotating table that carries the containers through the filling process.

- Gravity filling machines: These machines use gravity to fill products into containers. They are typically used for filling liquids that have a low viscosity.

2. Explain the process of setting up and calibrating a filling machine.

Pre-setup Checks

- Inspect the machine for any visible damage or wear.

- Check the lubrication levels and replenish if necessary.

- Ensure that all safety guards are in place and functioning properly.

Setup and Calibration

- Adjust the filling nozzles to the correct height and angle.

- Set the fill volume and speed according to the product specifications.

- Calibrate the machine using a known weight or volume of product.

- Run a test batch to verify the accuracy and consistency of the fill.

3. How do you troubleshoot common filling machine problems?

Troubleshooting filling machine problems involves identifying the root cause of the issue and implementing appropriate corrective actions.

- Underfilling or overfilling: Check the fill volume settings, nozzle alignment, and product viscosity.

- Leaking: Inspect the seals, gaskets, and hoses for any damage or wear.

- Clogged nozzles: Clear any blockages in the nozzles using a cleaning solution or a small brush.

- Machine malfunction: Check the electrical connections, sensors, and actuators for any faults.

4. What are the safety procedures for operating a filling machine?

To ensure safety while operating a filling machine, it is crucial to adhere to the following procedures:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Never reach into the filling area while the machine is in operation.

- Keep the work area clean and free of obstructions.

- Report any malfunctions or safety concerns to a supervisor immediately.

- Follow the manufacturer’s instructions for safe operation and maintenance.

5. How do you maintain and clean a filling machine?

Regular maintenance and cleaning are essential to ensure the optimal performance and longevity of a filling machine:

- Daily: Clean the filling nozzles, product contact surfaces, and exterior of the machine.

- Weekly: Inspect and lubricate moving parts, check the seals, and tighten any loose bolts.

- Monthly: Perform a thorough cleaning and sanitization of the entire machine, including the tanks and hoses.

- Annually: Schedule a comprehensive inspection and maintenance by a qualified technician.

6. What are the different types of filling machine controls?

Filling machines can be controlled through various types of control systems:

- Manual controls: Require the operator to manually set and adjust the filling parameters.

- Semi-automatic controls: Allow the operator to enter the desired fill volume, while the machine automatically fills the containers.

- Automatic controls: Fully automate the filling process, including container handling and filling, based on pre-programmed settings.

- PLC-based controls: Utilize programmable logic controllers (PLCs) to provide advanced control and monitoring capabilities.

7. How do you handle and resolve filling machine downtime?

To minimize downtime and maintain production efficiency, it is crucial to handle and resolve filling machine issues promptly:

- Identify the root cause of the downtime through troubleshooting.

- Implement corrective actions to fix the issue, such as replacing a faulty component or adjusting settings.

- Document the downtime and corrective actions for future reference and improvement.

- Communicate with supervisors and maintenance personnel to ensure timely resolution.

- Follow preventive maintenance schedules to minimize the risk of unexpected downtime.

8. What are the quality control measures you follow to ensure the accuracy and consistency of filled products?

To ensure product quality, I adhere to the following quality control measures:

- Regularly calibrate the filling machine using certified weights or volumes.

- Monitor the filling process visually and through automated sensors.

- Conduct random weight checks to verify fill accuracy.

- Inspect filled containers for any defects or leaks.

- Maintain records of quality control checks for traceability and documentation.

9. How do you stay updated with the latest advancements in filling machine technology?

To stay abreast of technological advancements in filling machinery, I engage in the following activities:

- Attend industry conferences and trade shows.

- Read technical publications and articles.

- Consult with equipment manufacturers and suppliers.

- Participate in training and certification programs.

- Network with other filling machine operators and technicians.

10. Describe a situation where you successfully resolved a complex filling machine issue.

In my previous role, I encountered an issue where the filling machine was consistently underfilling containers. I systematically:

- Checked the fill volume settings and nozzle alignment.

- Inspected the product viscosity and temperature.

- Verified the calibration of the filling head.

- Cleaned and inspected the product supply line for any blockages.

- Finally, I identified a faulty sensor that was providing incorrect feedback to the control system.

- By replacing the sensor, I resolved the issue and restored the filling accuracy to within acceptable limits.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filling Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filling Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Filling Machine Tenders are responsible for operating and maintaining filling machines which package solid and liquid products into containers such as boxes, bottles or bags. The key responsibilities include:

1. Machine Operation

Setting up and operating filling machines according to product and container specifications

- Loading and unloading containers onto and off of the filling machine

- Adjusting filling machine settings for different products and container sizes

2. Quality Control

Ensuring that products are filled to the correct weight or volume

- Inspecting containers for defects before and after filling

- Conducting product and container weight and volume checks according to quality standards

3. Machine Maintenance

Performing routine maintenance and troubleshooting of filling machines

- Replacing filters, cleaning sensors, and lubricating moving parts

- Identifying and resolving minor machine malfunctions

4. Sanitation and Safety

Maintaining a clean and sanitary work area around the filling machine

- Following proper safety procedures when operating filling machines and handling products

- Cleaning and sanitizing filling machines and work areas according to company and industry standards

Interview Tips

To ace the interview, candidates should prepare thoroughly. Here are some tips:

1. Research the Company and the Role:

Visit the company’s website to learn about their history, products or services, and company culture.

- Review the job description carefully to understand the key responsibilities and requirements.

- Prepare questions to ask the interviewer during the interview.

2. Highlight Relevant Experience and Skills:

In your resume and during the interview, emphasize your experience operating and maintaining filling machines or similar equipment.

- Quantify your accomplishments, providing specific examples of your contributions.

- Showcase your knowledge of quality control procedures and safety protocols.

3. Practice Answering Common Interview Questions:

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses.”

- Practice your answers out loud to build confidence and coherence.

- Use the STAR method to provide specific and detailed examples in your answers.

4. Dress Professionally and Be Punctual:

First impressions matter. Dress appropriately for the interview and arrive on time to demonstrate your respect for the interviewer’s time.

- Choose clean and pressed attire that is suitable for the work environment.

- Be mindful of your body language and maintain eye contact during the interview.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Filling Machine Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Filling Machine Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.