Are you gearing up for a career in Filling Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Filling Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

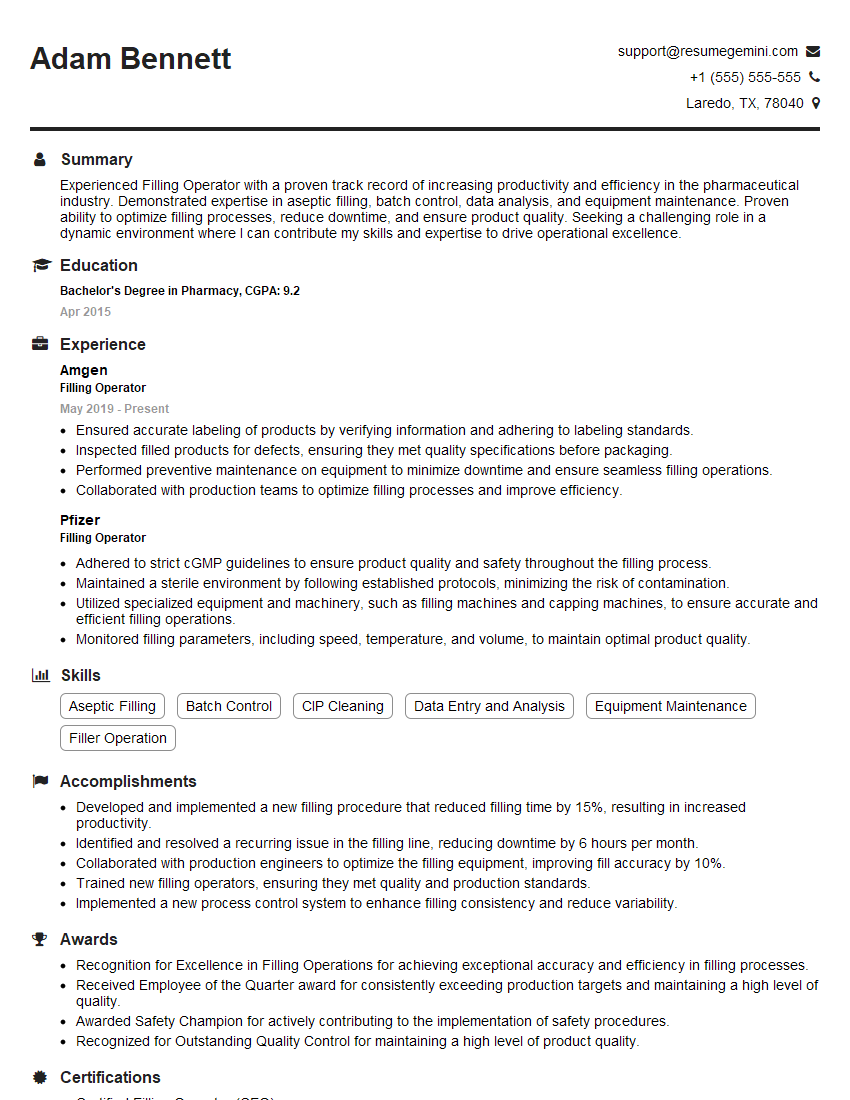

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filling Operator

1. What are the different types of filling machines and their uses?

There are several types of filling machines, each designed for different applications and products. Here are some common types:

- Gravity fillers: Use gravity to fill containers with liquid or semi-liquid products. They are simple and cost-effective for low-volume operations.

- Volumetric fillers: Dispense a precise volume of liquid or semi-liquid products by using pistons or gears. They offer accurate and consistent filling.

- Overflow fillers: Suitable for filling containers with foamy or viscous products. They fill containers until the product overflows and then shut off the flow.

- Net weight fillers: Measure the weight of the product being filled and adjust the fill volume accordingly. They are used for accurate filling of solids or semi-solids.

2. Explain how to calibrate a filling machine?

Zeroing the scale

- Ensure that the machine is leveled and the scale is clean.

- Place an empty container on the scale and press the “Tare” or “Zero” button to set the scale to zero.

Setting the fill volume

- Enter the desired fill volume into the machine’s control panel or adjust it using a knob or dial.

- Fill several containers and weigh them to ensure that the actual fill volume matches the set volume.

- Fine-tune the calibration as needed until the desired accuracy is achieved.

3. What are the common troubleshooting steps for filling machines?

Here are some common troubleshooting steps for filling machines:

- No filling: Check if the product supply is sufficient, the fill head is not clogged, and the machine is properly powered.

- Incorrect fill volume: Calibrate the machine, inspect the fill head for wear or damage, and ensure that the container is properly positioned.

- Leaking or dripping: Inspect the fill head, seals, and gaskets for damage or wear. Tighten loose connections and replace worn parts as needed.

- Foaming or overflow: Adjust the fill speed, check the product viscosity, and ensure that the product is not overfilled.

- Machine not starting: Check the power supply, fuses, and switches. Inspect the motor and drive system for any issues.

4. How do you ensure the accuracy and consistency of filling operations?

To ensure accuracy and consistency in filling operations, it is important to:

- Calibrate the filling machine regularly and maintain it in good working condition.

- Monitor the fill volume and make adjustments as needed to maintain the desired accuracy.

- Use consistent filling methods and techniques to minimize variations.

- Inspect filled containers for proper fill level and any defects.

- Implement quality control measures to monitor and improve the filling process.

5. What is the importance of maintaining a clean and sanitary work area in a filling operation?

Maintaining a clean and sanitary work area is crucial for the quality and safety of the filled products. It helps to:

- Prevent contamination of products with bacteria, allergens, or other harmful substances.

- Ensure that the filling equipment operates efficiently and accurately.

- Comply with food safety regulations and industry standards.

- Create a safe and healthy work environment for employees.

- Maintain the integrity and reputation of the company.

6. How do you handle spills or leaks during a filling operation?

To handle spills or leaks during a filling operation, it is important to follow these steps:

- Stop the filling process immediately to prevent further spillage.

- Identify the source of the leak and contain it using absorbent materials or a spill kit.

- Clean up the spilled product thoroughly to prevent contamination or slipping hazards.

- Inspect the filling equipment to determine the cause of the leak and repair it as needed.

- Report the incident and follow any required safety protocols or procedures.

7. What are the safety precautions that should be taken when operating a filling machine?

To ensure safety when operating a filling machine, it is important to follow these precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Be aware of moving parts and avoid loose clothing or jewelry that could get caught.

- Follow the manufacturer’s instructions and training procedures for operating the machine.

- Keep the work area clean and free of obstacles.

- Never reach into the filling area while the machine is running.

- Report any malfunctions or safety concerns immediately.

8. How do you optimize the filling process for efficiency and productivity?

To optimize the filling process for efficiency and productivity, consider the following strategies:

- Proper machine selection: Choose a filling machine that is suitable for the product and fill volume requirements.

- Efficient line layout: Design the filling line to minimize downtime and maximize workflow.

- Automation: Implement automated systems for loading, filling, and unloading to reduce manual labor.

- Preventive maintenance: Regularly maintain the filling equipment to prevent breakdowns and ensure smooth operation.

- Operator training: Train operators on proper filling techniques and safety procedures to optimize performance.

9. What are the challenges faced in filling different types of products?

Different types of products present unique challenges in filling operations:

- Liquids: Ensuring accurate and consistent fill volumes, handling foaming or viscous products, and minimizing spills.

- Semi-liquids: Controlling flow rates, preventing clogging or dripping, and maintaining product consistency.

- Solids: Filling containers to a specific weight or volume, handling fragile or delicate products, and preventing breakage.

- Powders: Controlling dust generation, ensuring uniform filling, and accommodating varying densities.

- Gases: Regulating pressure, ensuring safety, and monitoring fill levels accurately.

10. How do you stay updated with the latest advancements in filling technology?

To stay updated with the latest advancements in filling technology, I engage in the following practices:

- Industry events and conferences: Attend trade shows and industry events to learn about new machines, techniques, and trends.

- Trade publications and online resources: Read industry magazines, journals, and websites to stay informed about technological advancements.

- Manufacturer training and webinars: Participate in training programs and webinars offered by filling machine manufacturers to learn about their latest products and innovations.

- Networking with industry professionals: Connect with other filling professionals and share knowledge and experiences.

- Research and development: Stay curious and proactive in exploring new technologies and solutions that can enhance filling operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filling Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filling Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Filling Operators play a crucial role in packaging operations, ensuring that products are filled accurately and efficiently. Their key responsibilities include:

1. Filling and Packaging Products

Filling Operators operate and monitor filling machines to dispense liquids, powders, or other materials into containers.

- Adjust and calibrate filling machines to ensure accuracy and meet production standards.

- Monitor fill levels and make adjustments as needed to maintain consistency.

2. Quality Control and Inspection

They inspect filled containers for accuracy, weight, and appearance.

- Perform visual inspections of filled containers to identify any defects or spills.

- Ensure that all containers meet quality standards and customer specifications.

3. Equipment Maintenance and Troubleshooting

Filling Operators maintain filling machines and related equipment to ensure smooth and efficient operations.

- Clean and lubricate machines regularly to prevent malfunctions.

- Identify and resolve minor equipment issues.

4. Compliance and Safety

They adhere to safety regulations and maintain a clean and organized work area.

- Follow established safety protocols and wear appropriate protective gear.

- Maintain a clean and sanitized work environment to prevent contamination.

Interview Tips

To ace the interview for a Filling Operator position, candidates should:

1. Highlight Relevant Experience

Emphasize previous experience in filling operations, packaging, or related fields.

- Quantify accomplishments with specific examples of accuracy, efficiency, and quality control.

- Showcase a strong understanding of filling machine operations and troubleshooting.

2. Demonstrate Attention to Detail

Filling Operators must be meticulous and detail-oriented. Provide examples that highlight your ability to follow instructions, perform accurate inspections, and maintain cleanliness.

- Describe specific situations where you identified and resolved quality issues in filled products.

- Emphasize your ability to spot minor defects and ensure that all containers meet specifications.

3. Show Willingness to Learn and Adapt

Filling operations often involve new technologies and procedures.

- Express eagerness to learn about different filling machines and packaging techniques.

- Showcase a willingness to adapt to changes in production requirements and work schedules.

4. Highlight Team Player Skills

Filling Operators typically work in team environments.

- Provide examples of how you have effectively communicated with team members.

- Emphasize your ability to work collaboratively and contribute to a positive work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Filling Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!