Feeling lost in a sea of interview questions? Landed that dream interview for Filter Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Filter Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

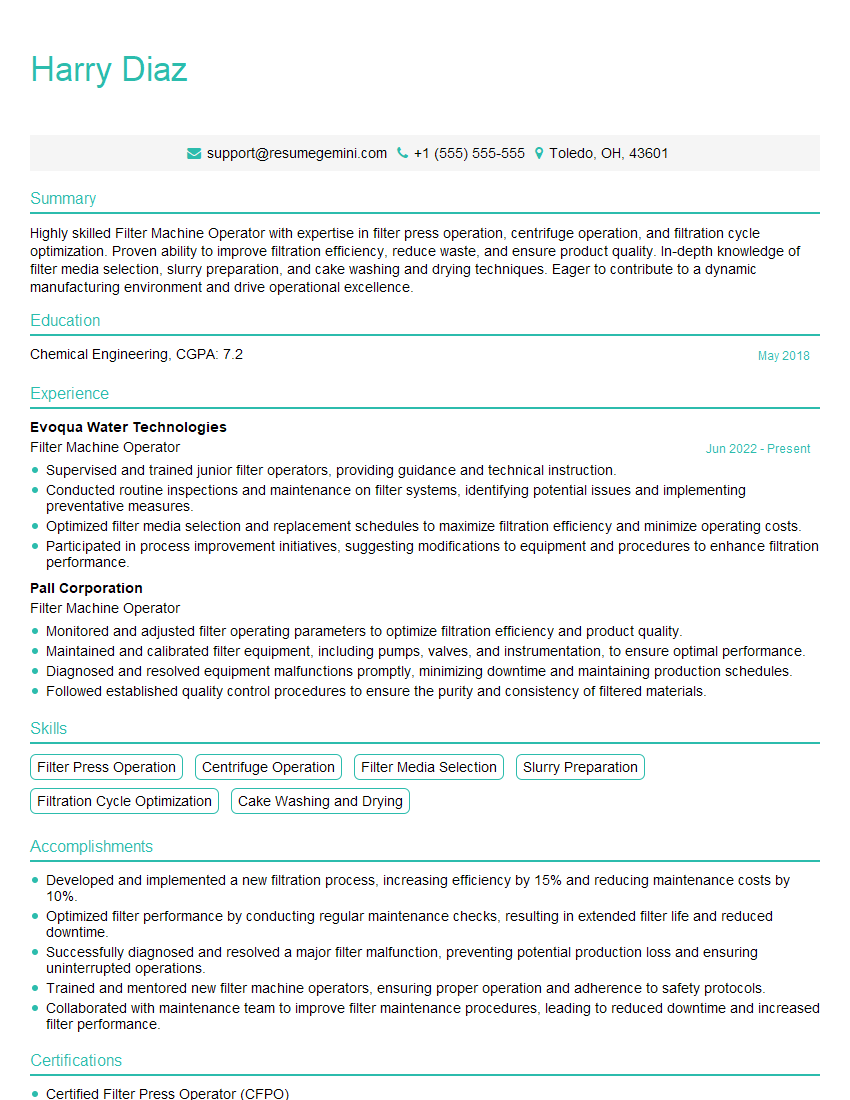

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filter Machine Operator

1. Describe the key responsibilities of a Filter Machine Operator.

- Operate and maintain filter machines to remove impurities from liquids or gases.

- Monitor equipment performance and make adjustments as needed to ensure optimal operation.

- Clean and maintain filters and related equipment to prevent contamination and ensure maximum efficiency.

2. Explain the different types of filter machines and their applications.

- Pressure filters: Used to separate solids from liquids by applying pressure to the liquid.

- Vacuum filters: Use a vacuum to draw liquid through a filter media, leaving solids behind.

- Centrifugal filters: Use centrifugal force to separate solids from liquids.

3. What factors should be considered when selecting a filter media?

- Particle size and shape

- Flow rate

- Pressure drop

- Chemical compatibility

- Cost

4. Discuss the importance of proper filter maintenance.

- Prevents contamination: Regular cleaning and maintenance help prevent impurities from entering the filtrate.

- Ensures optimal performance: Clean filters allow for efficient filtration and prevent equipment damage.

- Extends equipment life: Proper maintenance helps prolong the life of filter machines and reduces the need for costly repairs.

5. What troubleshooting steps would you take if a filter machine is not performing as expected?

- Check the filter media for clogging or damage.

- Inspect the seals and gaskets for leaks.

- Verify that the pressure and flow rate settings are correct.

- Check the power supply and electrical connections.

- Consult the manufacturer’s manual for additional troubleshooting tips.

6. How do you ensure the safety of yourself and others while operating filter machines?

- Wear appropriate personal protective equipment (PPE).

- Follow established safety protocols.

- Inspect equipment before each use.

- Do not operate machines that are damaged or malfunctioning.

- Be aware of potential hazards and take precautions to prevent accidents.

7. Explain how you would handle a situation where a filter machine is leaking.

- Identify the source of the leak.

- Stop the flow of liquid or gas through the machine.

- Contact a supervisor or maintenance technician.

- Take steps to contain the leak and prevent further contamination.

- Follow company safety protocols for hazardous spills.

8. Describe your experience with different types of filtration systems.

- Membrane filtration: Pressure-driven process that separates particles based on size.

- Adsorption filtration: Removes particles by trapping them on the surface of an adsorbent material.

- Electrostatic filtration: Uses charged plates to attract and collect particles.

9. How do you stay up-to-date on industry best practices for filter operation?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Consult with equipment manufacturers and suppliers.

- Participate in online forums and discussion groups.

- Seek feedback from colleagues and supervisors.

10. What are your career aspirations?

- Advance to a supervisory role within the filtration department.

- Become an expert in a specific type of filtration technology.

- Develop new and innovative filtration solutions.

- Contribute to the advancement of the filtration industry.

- Utilize my skills and experience to increase company efficiency and productivity.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filter Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filter Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Filter Machine Operators are reliable individuals who play a significant role in ensuring the smooth and efficient operation of filter machines in various industrial settings. Their core responsibilities encompass:

1. Machine Operation and Maintenance

Filter Machine Operators are responsible for the seamless operation of filter machines, which purify and separate liquids and solids through filtration. They ensure that the machines are functioning optimally, adjusting settings, monitoring gauges, and performing regular maintenance tasks.

- Calibrating and adjusting machine settings to achieve desired filtration results

- Inspecting and cleaning filter media, such as screens, membranes, and cartridges

2. Process Monitoring and Control

Operators closely monitor the filtration process, analyzing data and making adjustments as needed. They maintain precise control over key parameters, such as pressure, flow rate, and temperature, to ensure the desired outcome.

- Observing and recording filtration parameters

- Adjusting process variables to optimize efficiency and product quality

3. Quality Control and Assurance

Filter Machine Operators play a crucial role in maintaining product quality. They conduct regular inspections and tests to ensure that filtered products meet established standards and specifications.

- Collecting and analyzing samples for quality control purposes

- Identifying and resolving quality issues promptly

4. Health and Safety Compliance

Operators are responsible for adhering to strict safety protocols and maintaining a clean and organized work environment. They wear appropriate personal protective equipment (PPE) and follow established safety guidelines.

- Complying with safety regulations and following established procedures

- Maintaining a safe and clean work area

Interview Tips

To ace the Filter Machine Operator interview, candidates should be well-prepared and demonstrate their knowledge and skills. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, take time to research the company and the specific role. Understand their industry, products or services, and the company culture. This knowledge will help you connect with the interviewer and answer questions thoughtfully.

- Read the job description carefully and identify key responsibilities.

- Visit the company’s website to learn about their mission, values, and recent projects.

2. Highlight Your Technical Skills and Experience

Emphasize your technical skills and experience in operating filter machines. Quantify your accomplishments and provide specific examples of how you have contributed to the success of previous filtration projects.

- Describe your experience with different types of filter machines and filtration processes.

- Provide examples of how you have optimized filtration efficiency or improved product quality.

3. Showcase Your Understanding of Quality Control

Interviewers will be interested in your understanding of quality control procedures. Explain how you have ensured product quality and compliance with industry standards in your previous roles.

- Explain your knowledge of quality control techniques and equipment.

- Describe your experience in troubleshooting and resolving quality issues.

4. Demonstrate Your Safety Consciousness

Safety is paramount in industrial settings. Emphasize your commitment to safety by highlighting your experience in adhering to safety regulations and maintaining a safe work environment.

- Explain your understanding of industry safety standards and best practices.

- Describe your experience in conducting safety inspections and implementing safety measures.

5. Be Enthusiastic and Confident

Convey your enthusiasm for the role and the industry. Show the interviewer that you are confident in your abilities and eager to contribute to the team. Be respectful and ask thoughtful questions to demonstrate your interest and engagement.

- Express your interest in the company and the specific position.

- Ask questions to clarify the role and the company’s expectations.

Next Step:

Now that you’re armed with the knowledge of Filter Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Filter Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini