Feeling lost in a sea of interview questions? Landed that dream interview for Filter Washer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Filter Washer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

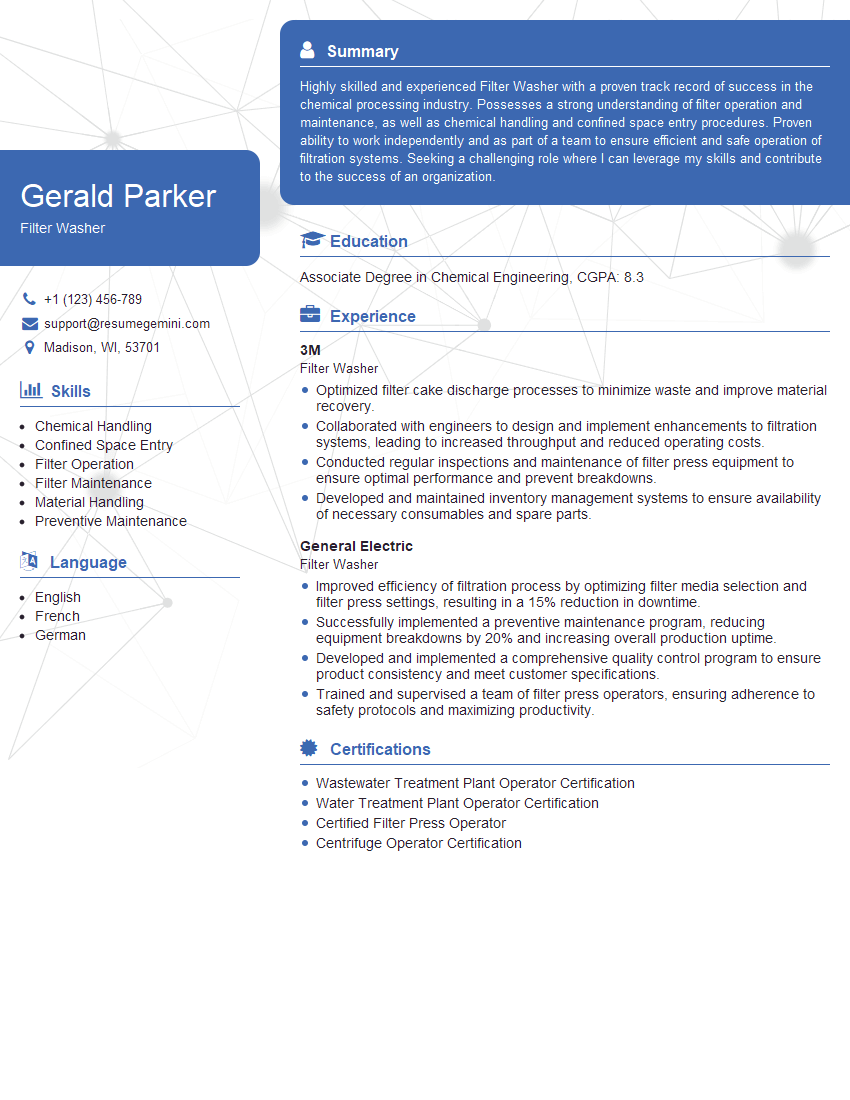

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filter Washer

1. What are the key responsibilities of a Filter Washer?

- Operate and maintain filter washing equipment

- Monitor filter performance and make adjustments as needed

- Clean and maintain filter media

- Troubleshoot and repair filter equipment

- Follow safety procedures and regulations

2. What are the different types of filter washing equipment?

- Rotary drum filters

- Belt filters

- Disk filters

- Leaf filters

- Pressure filters

3. What are the key factors to consider when selecting a filter washing equipment?

- The type of material being filtered

- The flow rate of the material being filtered

- The size of the particles being filtered

- The desired level of filtration

- The cost of the equipment and maintenance

4. How do you maintain a filter washing equipment?

Regular maintenance is essential to keep filter washing equipment in good working order. Some common maintenance tasks include:

- Cleaning the filter media

- Lubricating the moving parts

- Checking the belts and hoses for wear and tear

- Calibrating the equipment

- Troubleshooting and repairing any problems

5. What are the safety precautions that must be taken when operating a filter washing equipment?

- Wear appropriate personal protective equipment (PPE)

- Follow all lockout/tagout procedures

- Be aware of the potential hazards of the material being filtered

- Do not attempt to operate the equipment if it is damaged or malfunctioning

- Report any accidents or injuries to your supervisor immediately

6. What are the common problems that can occur with filter washing equipment?

- Clogging of the filter media

- Leaks in the equipment

- Failure of the pump or motor

- Electrical problems

- Mechanical problems

7. How do you troubleshoot a filter washing equipment?

If a filter washing equipment is not working properly, it is important to troubleshoot the problem quickly and efficiently.

- First, check the equipment for any obvious problems, such as leaks or damage.

- Next, check the power supply to the equipment to make sure that it is working properly.

- If the power supply is working properly, then you can start to troubleshoot the equipment itself.

- Start by checking the filter media. If the filter media is clogged, it will need to be cleaned or replaced.

- If the filter media is not clogged, then you can check the pump and motor. The pump and motor are responsible for circulating the water through the filter.

- If the pump and motor are working properly, then you can check the electrical system. The electrical system is responsible for controlling the operation of the equipment.

- If the electrical system is working properly, then you can check the mechanical system. The mechanical system is responsible for the movement of the filter media.

8. What are the different types of filter media that can be used in a filter washing equipment?

- Woven fabrics

- Non-woven fabrics

- Membranes

- Ceramic materials

- Metal materials

9. What are the advantages and disadvantages of using different types of filter media?

| Type of Filter Media | Advantages | Disadvantages |

|---|---|---|

| Woven fabrics |

|

|

| Non-woven fabrics |

|

|

| Membranes |

|

|

| Ceramic materials |

|

|

| Metal materials |

|

|

10. What are the key performance indicators (KPIs) for a Filter Washer?

- Filter efficiency

- Filter capacity

- Filter downtime

- Filter maintenance costs

- Filter energy consumption

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filter Washer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filter Washer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Filter Washers are responsible for the operation, maintenance, and troubleshooting of filter presses. They work with highly pressurized machines and chemicals, so it’s important to have a strong understanding of safety protocols and proper equipment operation.

1. Operate Filter Presses

Filter Washers are responsible for the safe and efficient operation of filter presses. This includes:

- Loading the filter press with filter media

- Starting the filter press and monitoring its operation

- Adjusting the filter press controls to ensure optimal performance

- Unloading the filter press and cleaning the filter media

2. Maintain Filter Presses

Filter Washers are also responsible for the maintenance of filter presses. This includes:

- Inspecting the filter press for any damage or wear

- Lubricating the filter press as needed

- Replacing any worn or damaged parts

- Calibrating the filter press to ensure accuracy

3. Troubleshooting Filter Presses

Filter Washers are responsible for troubleshooting any problems that may occur with filter presses. This includes:

- Identifying the source of the problem

- Developing and implementing a solution

- Testing the solution to ensure it is effective

4. Other Duties

Filter Washers may also be responsible for other duties, such as:

- Cleaning the work area

- Assisting other workers

- Following safety protocols

Interview Tips

Preparing for an interview can be nerve-wracking, but there are several things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Filter Washer position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. Be sure to check the company website, read the job description, and learn as much as you can about the company’s culture and values. This will help you understand the company’s needs and demonstrate your interest in the position.

2. Practice your answers to common interview questions

There are certain questions that are commonly asked in interviews for Filter Washer positions. Some of the most common questions include:

- Tell me about your experience with filter presses.

- What are your strengths and weaknesses?

- Why are you interested in this position?

- What are your salary expectations?

- What is your availability?

3. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also arrive on time for your interview. Punctuality shows that you are respectful of the interviewer’s time and that you are serious about the position.

4. Be yourself and be positive

During the interview, be yourself and let your personality shine through. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be positive and enthusiastic. This will show the interviewer that you are excited about the opportunity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Filter Washer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Filter Washer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.