Are you gearing up for an interview for a Filtering Machine Tender Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Filtering Machine Tender Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

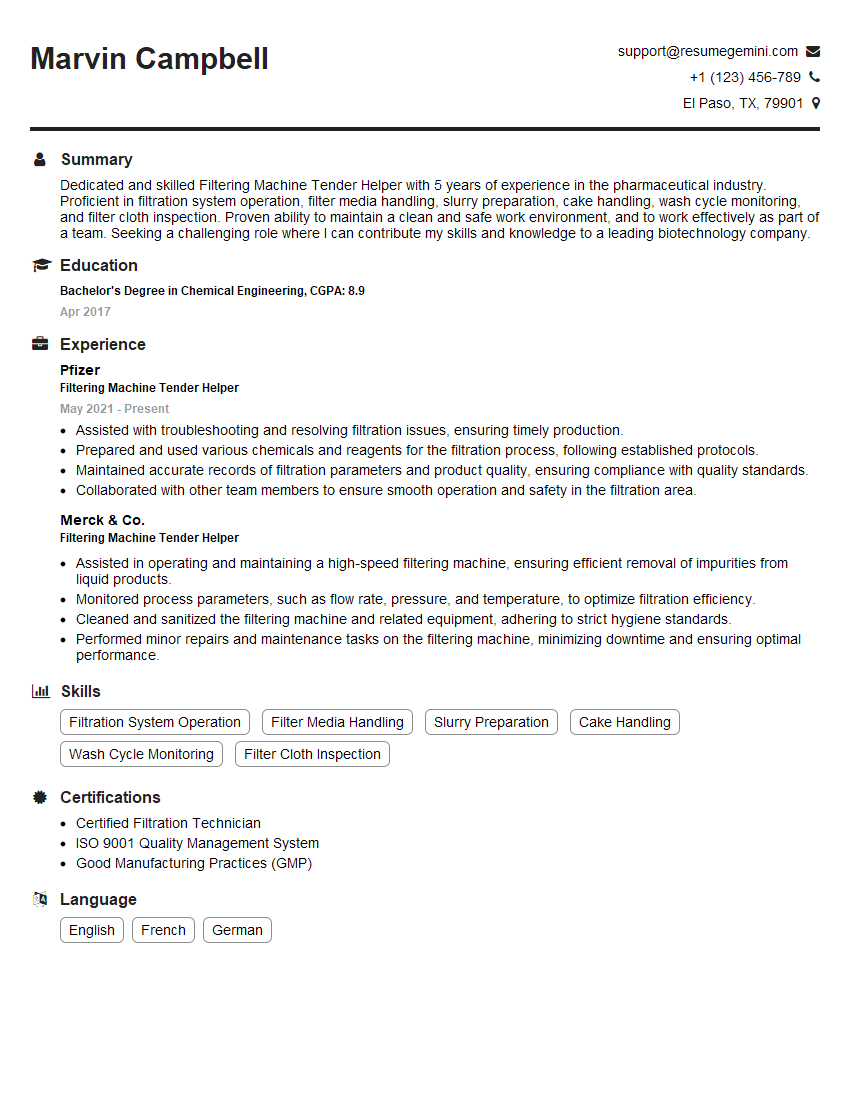

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filtering Machine Tender Helper

1. What is the purpose of a filter press and how does it work?

- A filter press is a machine used to separate solids from liquids by applying pressure to a slurry.

- The slurry is pumped into the filter press and forced through a filter cloth, which traps the solids while allowing the liquid to pass through.

2. What are the different types of filter presses and what are their advantages and disadvantages?

Recessed Chamber Filter Press

- Advantages: High pressure, good filtration efficiency, easy to operate.

- Disadvantages: High cost, large space requirement.

Membrane Filter Press

- Advantages: Good filtration efficiency, low energy consumption, small space requirement.

- Disadvantages: High cost, not suitable for high temperature and corrosive materials.

Automatic Filter Press

- Advantages: High degree of automation, labor saving, and high filtration efficiency.

- Disadvantages: High cost, complex structure.

3. What are the key factors to consider when selecting a filter press for a specific application?

- The type of slurry to be filtered

- The desired filtration efficiency

- The available space and budget

4. How do you maintain a filter press to ensure optimal performance?

- Regularly clean the filter cloth to prevent clogging.

- Inspect the filter plates for wear and tear.

- Lubricate the moving parts of the filter press.

- Calibrate the pressure gauges to ensure accurate readings.

5. What are the safety precautions that must be taken when operating a filter press?

- Wear appropriate personal protective equipment, such as gloves, goggles, and a dust mask.

- Do not operate the filter press if it is damaged or malfunctioning.

- Be aware of the potential for leaks and spills.

- Follow all manufacturer’s instructions for safe operation.

6. What are the common problems that can occur with filter presses and how do you troubleshoot them?

- Clogging of the filter cloth: Clean the filter cloth or replace it if necessary.

- Leaking: Check the gaskets and seals for wear and tear and replace them if necessary.

- Low filtration efficiency: Check the filter cloth for clogging or damage and replace it if necessary.

- High pressure drop: Check the filter cloth for clogging or damage and replace it if necessary.

7. What are the best practices for maximizing the efficiency of a filter press?

- Use a filter cloth that is appropriate for the type of slurry being filtered.

- Pre-coat the filter cloth with a layer of filter aid to improve filtration efficiency.

- Operate the filter press at the optimal pressure for the type of slurry being filtered.

- Clean the filter cloth regularly to prevent clogging.

8. What are the latest trends in filter press technology?

- The use of automatic filter presses to reduce labor costs.

- The development of new filter cloths with improved filtration efficiency.

- The use of membrane filter presses for high-temperature and corrosive applications.

9. What are the key challenges facing the filter press industry?

- The increasing cost of raw materials.

- The growing demand for high-performance filter presses.

- The need to reduce the environmental impact of filter press operations.

10. What are your strengths and weaknesses as a Filter Machine Tender Helper?

Strengths

- I am a hard worker and I am always willing to learn new things.

- I am a team player and I am always willing to help out my colleagues.

- I have a strong attention to detail and I am always careful to follow instructions.

Weaknesses

- I am sometimes too eager to get the job done and I can make mistakes if I am not careful.

- I am not always the best at communicating with others, but I am always willing to listen and learn.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filtering Machine Tender Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filtering Machine Tender Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Filtering Machine Tender Helper is responsible for assisting the Filtering Machine Tender in the operation and maintenance of filtering machines. This role is crucial in ensuring the production of high-quality filtered products while maintaining a safe and efficient work environment.

1. Machine Operation and Maintenance

Assists the Filtering Machine Tender in operating and monitoring filtering machines

- Starts, stops, and adjusts machines according to instructions

- Monitors machine operation, identifies potential problems, and takes corrective actions

2. Filter Media Handling

Assists in the preparation, installation, and removal of filter media

- Selects appropriate filter media based on product specifications

- Installs filter media correctly and securely to ensure proper filtration

3. Product Handling

Assists in the handling of filtered products

- Unloads filtered products from machines

- Inspects products for quality and consistency

4. Cleaning and Sanitation

Maintains a clean and sanitary work environment

- Cleans and sanitizes machines and equipment regularly

- Inspects and maintains sanitation standards to ensure product quality

Interview Tips

Preparing thoroughly for a Filtering Machine Tender Helper interview can significantly increase your chances of success. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Take time to research the company and the specific responsibilities of the Filtering Machine Tender Helper position. This will demonstrate your interest and enthusiasm for the role and allow you to ask informed questions during the interview.

- Visit the company’s website to learn about their products, services, and culture.

- Read job descriptions and company reviews to understand the specific requirements and expectations of the position.

2. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. By practicing your answers, you can become more confident and articulate during the interview.

- Practice questions such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

3. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience that align with the job responsibilities. Quantify your accomplishments whenever possible to demonstrate your impact.

- Mention any prior experience in operating or assisting with filtering machines.

- Highlight your knowledge of filter media and product handling procedures.

- Showcase your attention to detail, cleanliness, and ability to work in a fast-paced environment.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position and the company. It also gives you an opportunity to clarify any remaining questions.

- Ask about the company’s growth plans, industry trends, or specific aspects of the role that you are curious about.

- Avoid asking questions that have already been answered during the interview or that are easily found on the company’s website.

5. Follow Up

After the interview, send a thank-you note to the interviewer within 24-48 hours. Express your appreciation for their time and reiterate your interest in the position. You can also use the follow-up to clarify any points or ask additional questions that may have arisen after the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Filtering Machine Tender Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!