Are you gearing up for a career in Filtering Machine Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Filtering Machine Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

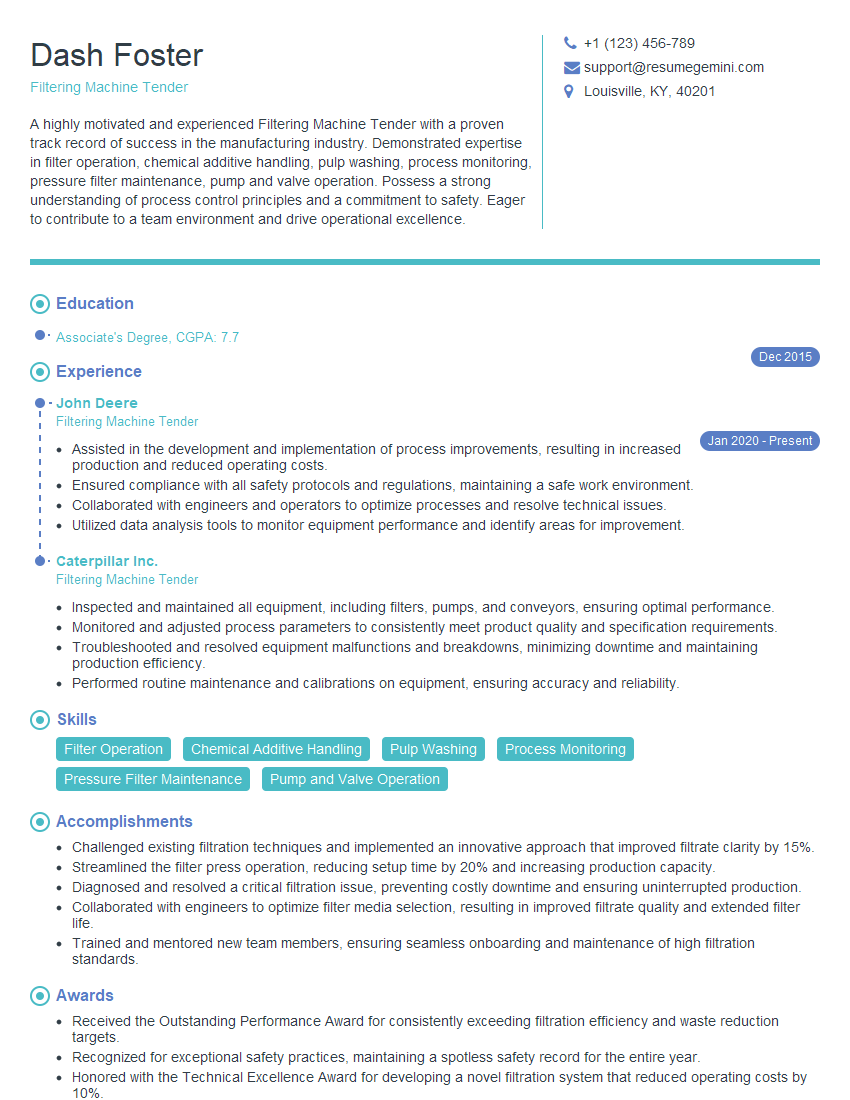

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filtering Machine Tender

1. Describe the primary responsibilities of a Filtering Machine Tender?

- Operate and monitor filtering machines to separate solids from liquids.

- Ensure that machines are functioning properly and make necessary adjustments.

- Inspect and maintain equipment, including cleaning and repairing filters.

2. How do you handle situations where the filtering machine malfunctioned or experienced unexpected downtime?

Troubleshooting:

- Identify the source of the problem.

- Consult with maintenance personnel if necessary.

- Resolve the issue promptly.

Communication:

- Inform the supervisor and other relevant personnel.

- Keep records of the downtime and corrective actions taken.

3. Explain the importance of maintaining accurate records in filtering operations?

- To track production output and efficiency.

- To monitor filter performance and identify potential issues.

- To comply with regulatory requirements and ensure product quality.

4. What safety precautions should be taken when operating a filtering machine?

- Wear appropriate protective gear, including gloves, masks, and safety goggles.

- Handle hazardous materials safely.

- Be aware of potential hazards, such as pressure buildup or leaks.

5. Describe your experience in optimizing filtering processes to improve efficiency and product quality?

- Adjusting filter settings to optimize particle removal.

- Monitoring feed rates and pressures to prevent clogging.

- Implementing preventive maintenance schedules to ensure consistent performance.

6. How do you stay up-to-date with industry best practices and technological advancements in filtering?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Consult with equipment manufacturers and industry experts.

7. Explain the difference between pressure filtration and vacuum filtration?

- Pressure filtration: Liquid is forced through a filter medium under pressure, leaving solids behind.

- Vacuum filtration: A vacuum is created to draw liquid through a filter medium, leaving solids on the surface.

8. Describe the role of filter media in filtration processes?

- To retain solids while allowing liquids to pass through.

- To provide different levels of filtration efficiency.

- To be chemically compatible with the materials being filtered.

9. Explain how you would troubleshoot a problem with a filter that is not producing the desired results?

- Check the filter media for clogging or damage.

- Verify the correct filter settings are being used.

- Inspect the feed material for any unusual characteristics.

10. What is the importance of regular maintenance and calibration of filtering machines?

- To ensure optimal performance and efficiency.

- To prevent breakdowns and downtime.

- To maintain product quality and safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filtering Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filtering Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Filtering Machine Tenders are responsible for the smooth operation of filtering machines, ensuring adherence to quality standards.

1. Machine Operation

Start, stop, and monitor the operation of filtering machines.

- Load and unload filters according to specifications.

- Adjust machine settings to optimize performance.

2. Product Quality Monitoring

Inspect and ensure the quality of filtered products.

- Take samples and conduct tests to verify product specifications.

- Identify and resolve any quality issues promptly.

3. Equipment Maintenance

Perform routine maintenance and repairs on filtering machines.

- Clean and inspect equipment to prevent breakdowns.

- Replace worn or damaged parts as needed.

4. Process Control

Control and adjust the filtering process to ensure efficiency and productivity.

- Monitor process parameters such as temperature and flow rate.

- Make adjustments to optimize machine performance and reduce waste.

Interview Tips

To ace the interview for a Filtering Machine Tender position, consider the following tips:

1. Research the Industry and Company

Understand the industry trends and the specific operations of the company you are applying to.

- Familiarize yourself with different types of filtering machines and their applications.

- Learn about the company’s products, processes, and quality standards.

2. Showcase Your Technical Skills

Demonstrate your proficiency in operating and maintaining filtering machines.

- Highlight your experience in troubleshooting and resolving equipment issues.

- Provide examples of how you have used your technical knowledge to improve process efficiency.

3. Emphasize Quality Control

Emphasize your commitment to maintaining product quality.

- Discuss your experience in conducting quality inspections and taking corrective actions.

- Explain your understanding of quality assurance procedures and standards.

4. Prepare for Common Questions

Anticipate questions related to your experience, skills, and work ethic.

- Practice answering behavioral questions using the STAR method (Situation, Task, Action, Result).

- Be prepared to discuss your strengths, weaknesses, and how you handle challenges.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Filtering Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!