Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Filters Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Filters Assembler so you can tailor your answers to impress potential employers.

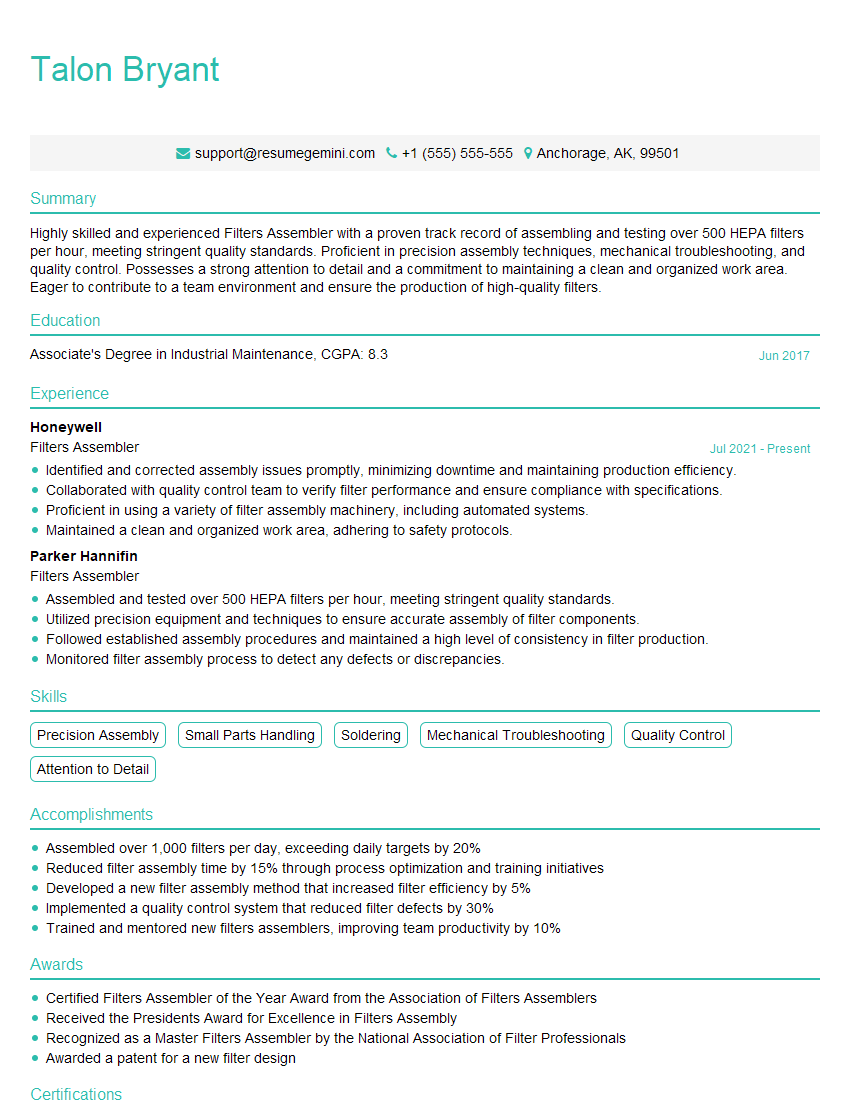

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filters Assembler

1. Explain the key responsibilities of a Filters Assembler?

- Assembling and testing various types of filters, including air filters, fuel filters, and oil filters.

- Reading and interpreting blueprints and schematics.

- Operating and maintaining assembly equipment.

- Inspecting and testing filters to ensure they meet quality standards.

- Troubleshooting and repairing filters as needed.

2. Describe the different types of filters you have assembled in the past?

Air filters:

- Pleated air filters

- HEPA filters

- Carbon filters

Fuel filters:

- Spin-on fuel filters

- Canister fuel filters

- Inline fuel filters

Oil filters:

- Spin-on oil filters

- Cartridge oil filters

- Full-flow oil filters

3. What are the most important quality control checks you perform when assembling filters?

- Checking the dimensions of the filter to ensure it meets specifications.

- Inspecting the filter media for any tears or defects.

- Testing the filter to ensure it meets the required flow rate and efficiency.

- Checking the filter for any leaks.

- Ensuring the filter is properly labeled and packaged.

4. What are the different types of assembly equipment you have experience operating?

- Filter presses

- Filter winders

- Filter pleating machines

- Filter testing equipment

- Material handling equipment

5. How do you troubleshoot and repair filters?

- Inspecting the filter for any obvious damage.

- Testing the filter to identify the problem.

- Replacing any damaged components.

- Cleaning the filter and reassembling it.

- Retesting the filter to ensure it is functioning properly.

6. What are the safety precautions you take when working with filters?

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a dust mask.

- Working in a well-ventilated area.

- Being aware of the potential hazards associated with the materials being used.

- Following all safety procedures and guidelines.

- Reporting any accidents or injuries immediately.

7. How do you stay up-to-date on the latest filter assembly techniques and technologies?

- Reading industry publications and attending trade shows.

- Taking online courses and workshops.

- Networking with other filter assembly professionals.

- Participating in research and development projects.

- Seeking feedback from customers and suppliers.

8. What are your strengths as a Filters Assembler?

- Attention to detail

- Strong mechanical skills

- Ability to work independently and as part of a team

- Commitment to quality

- Ability to troubleshoot and solve problems

9. What are your weaknesses as a Filters Assembler?

- I am sometimes too detail-oriented and can get bogged down in the small things.

- I can be a bit of a perfectionist and sometimes it is difficult for me to let go of a project until it is perfect.

- I am not always the best at working under pressure.

- I am not always the most organized person.

- I am not always the best at communicating with others.

10. Why are you interested in working as a Filters Assembler?

- I am passionate about manufacturing and I enjoy working with my hands.

- I am interested in the filtration industry and I believe that filters are an important part of our world.

- I am confident that I have the skills and experience necessary to be a successful Filters Assembler.

- I am eager to learn more about the filter assembly process and I am excited to contribute to your company’s success.

- I am looking for a challenging and rewarding career where I can make a difference.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filters Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filters Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Filters Assemblers play a crucial role in manufacturing and assembling various types of filters, including air filters, water filters, and oil filters. Their primary responsibilities encompass:

1. Assembly and Fabrication

Assemblers are responsible for assembling and fabricating filter components according to specifications and quality standards. This involves:

- Selecting and preparing raw materials, such as filter media, frames, and gaskets.

- Assembling components using precision tools and techniques, ensuring accuracy and durability.

- Fabricating custom filters based on specific customer requirements and design specifications.

2. Quality Control and Inspection

Ensuring the quality and performance of filters is paramount. Assemblers perform rigorous quality control measures, including:

- Inspecting assembled filters for defects, leaks, or inconsistencies, using specialized equipment and testing methods.

- Testing filters for performance parameters such as air flow rate, pressure drop, and efficiency.

- Maintaining accurate records and documentation of quality control procedures and findings.

3. Equipment Maintenance

Assemblers are responsible for maintaining and calibrating the equipment used in filter assembly, such as:

- Setting up and operating machinery, including cutters, presses, and welding equipment.

- Performing routine maintenance procedures, such as cleaning, lubrication, and adjustments.

- Troubleshooting and resolving equipment issues to ensure efficient and uninterrupted production.

4. Production Optimization

Assemblers actively contribute to improving production processes and efficiency by:

- Identifying and implementing improvements in assembly techniques and equipment.

- Adopting lean manufacturing principles to minimize waste and increase productivity.

- Collaborating with other team members to optimize production schedules and meet delivery deadlines.

Interview Tips

To ace an interview for a Filters Assembler position, preparing thoroughly and showcasing your skills and experience is essential. Here are some valuable tips:

1. Research the Industry and Company

Demonstrate a genuine interest in the industry you’re applying to. Familiarize yourself with the filter manufacturing process, different filter types, and the company’s products and reputation. Researching the company culture and values will also show your enthusiasm and commitment.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on skills in filter assembly, fabrication, and quality control. Provide specific examples of projects you’ve worked on, the equipment you’re proficient in, and the quality standards you’ve met. Quantify your accomplishments whenever possible to demonstrate your impact.

3. Showcase Attention to Detail

Filters Assemblers must be meticulous and detail-oriented. Emphasize your ability to work precisely, follow instructions carefully, and maintain a clean and organized work environment. Highlight instances where you identified and resolved quality issues, ensuring the highest standards of production.

4. Convey Flexibility and Adaptability

Manufacturing environments can be dynamic and fast-paced. Illustrate your ability to adapt to changing production schedules, handle multiple tasks simultaneously, and work under pressure. Mention experiences where you transitioned between different tasks or projects, demonstrating your versatility.

5. Prepare Questions

Asking insightful questions during the interview shows your interest and engagement. Prepare questions about the company’s growth plans, the products they manufacture, and the industry trends. Asking about the company’s commitment to quality and innovation can also reveal their priorities and values.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Filters Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!