Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Filtration Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Filtration Supervisor so you can tailor your answers to impress potential employers.

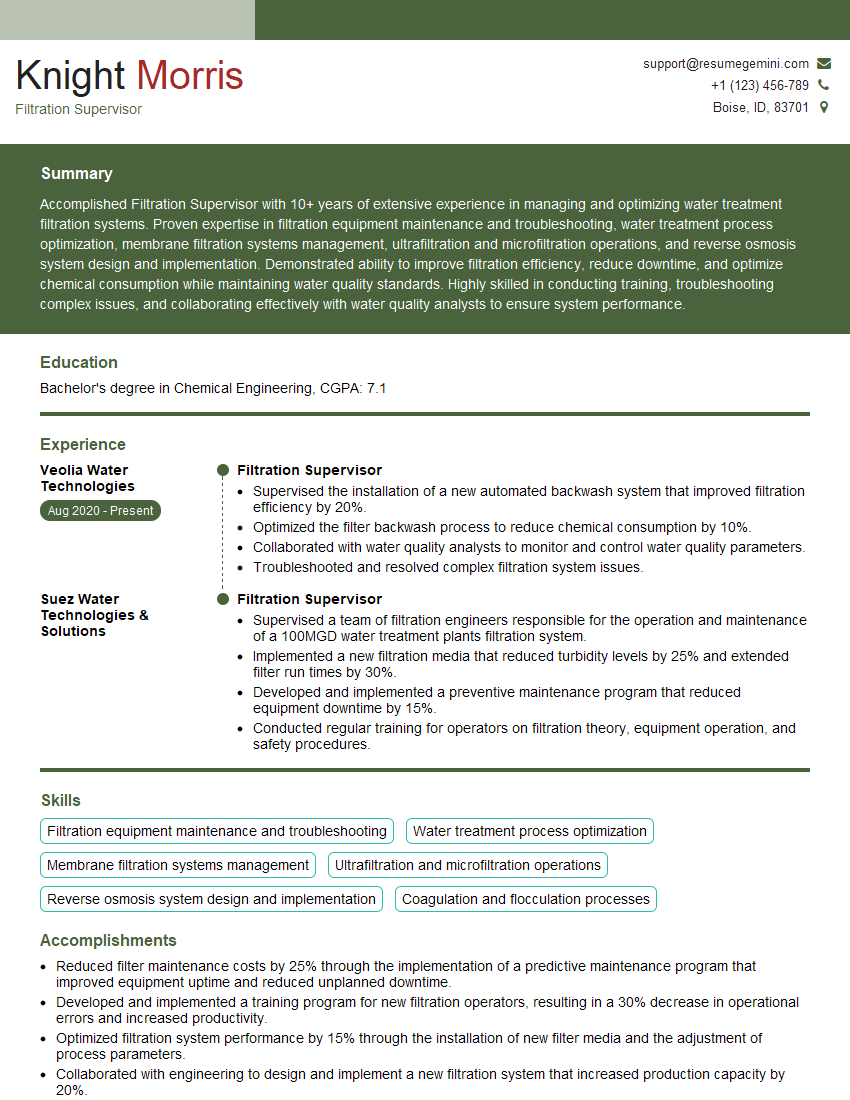

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Filtration Supervisor

1. What are the different types of filters used in water treatment plants?

There are various types of filters used in water treatment plants, including:

- Bag filters: Used to remove suspended solids and particles.

- Cartridge filters: Made from pleated or wound materials to capture contaminants.

- Depth filters: Consist of a porous media that traps particles throughout its depth.

- Membrane filters: Utilize semi-permeable membranes to remove microorganisms and dissolved solids.

- Sand filters: Beds of sand that remove solids through physical straining and filtration.

- Activated carbon filters: Contain activated carbon to adsorb organic contaminants and improve water taste.

2. Describe the process of backwashing a filter.

Reversing the water flow

- Water is directed backward through the filter media to dislodge accumulated solids.

- This helps clean the filter and restore its filtration efficiency.

Air scouring

- Air is introduced into the backwash water to enhance the removal of particles.

- The air bubbles create turbulence and help lift and dislodge solids.

Draining the backwash water

- The backwash water, containing the removed solids, is drained from the system.

3. What are the key performance indicators (KPIs) used to monitor the performance of a filtration system?

KPIs for filtration systems include:

- Turbidity: Measures the clarity of the filtered water.

- Head loss: Indicates the pressure drop across the filter, indicating the level of fouling.

- Flow rate: Monitors the volume of water passing through the filter.

- Particle count: Assesses the removal efficiency of particles within a specific size range.

- Microbial counts: Determines the presence and concentration of microorganisms in the filtered water.

4. How do you optimize the operation of a filtration system to achieve maximum efficiency?

Optimizing filtration systems involves:

- Regular monitoring and analysis: Tracking KPIs and identifying areas for improvement.

- Scheduled maintenance: Performing routine cleaning and replacing filter elements to prevent fouling.

- Coagulation and flocculation: Using chemical additives to enhance particle removal before filtration.

- Optimizing backwash parameters: Adjusting the flow rate and duration to effectively remove solids.

- Filter media selection: Choosing the appropriate media based on the target contaminants and water quality.

5. What are the potential causes of membrane fouling in ultrafiltration systems?

Membrane fouling in ultrafiltration systems can be caused by:

- Scaling: Deposition of mineral salts or precipitates on the membrane surface.

- Colloidal fouling: Accumulation of fine particles or colloids that block the membrane pores.

- Organic fouling: Formation of a layer of organic matter, such as proteins or biofilms, on the membrane.

- Biological fouling: Growth of microorganisms on the membrane surface, which can create a biofilm.

6. How do you troubleshoot a filtration system that is producing poor-quality water?

Troubleshooting filtration systems involves:

- Identifying the source of the problem: Analyzing water quality data, inspecting filter components, and checking operational parameters.

- Cleaning or replacing filter elements: Removing accumulated solids or replacing damaged elements.

- Adjusting system parameters: Optimizing backwash frequency, flow rates, and other operating conditions.

- Investigating potential contamination sources: Identifying and eliminating any sources of contaminants upstream of the filtration system.

- Contacting the equipment manufacturer: Seeking technical support and guidance from the experts.

7. What are the safety procedures that must be followed when working with filtration systems?

Safety procedures for filtration systems include:

- Wear appropriate personal protective equipment (PPE): Gloves, safety glasses, and hearing protection.

- Lock out and tag out equipment: Isolate systems before performing any maintenance or repairs.

- Handle chemicals safely: Follow proper procedures for mixing, storing, and disposing of chemicals.

- Be aware of potential hazards: Identify and assess potential risks, such as slippery surfaces or high-pressure lines.

- Follow emergency response plans: Know the procedures for responding to accidents or spills.

8. How do you stay up-to-date on the latest advances and best practices in filtration technology?

To stay updated on filtration technology, I engage in several practices:

- Attend industry conferences and workshops: Participate in events where experts share knowledge and discuss new developments.

- Read technical journals and publications: Review articles and case studies to stay informed about advancements and research.

- Connect with industry professionals: Network with peers, suppliers, and experts to exchange ideas and learn about emerging technologies.

- Seek training and certifications: Enhance my skills and knowledge through formal training programs and certification courses.

- Collaborate with equipment manufacturers: Engage with manufacturers to learn about new products and technologies, as well as receive technical support.

9. How do you motivate and lead a team of filtration operators?

To motivate and lead a team of filtration operators, I employ the following strategies:

- Clear communication: Establish clear expectations, provide regular updates, and foster open dialogue.

- Recognition and appreciation: Acknowledge and reward team members for their contributions and successes.

- Empowerment: Delegate responsibilities and provide opportunities for team members to contribute their ideas and take ownership.

- Team building: Organize team-building activities and encourage collaboration to foster a positive and supportive work environment.

- Training and development: Provide ongoing training and support to enhance team members’ skills and knowledge.

10. What is your approach to ensuring compliance with environmental regulations related to filtration systems?

My approach to ensuring compliance with environmental regulations related to filtration systems includes:

- Understanding the regulations: Thoroughly review and understand all applicable environmental regulations and industry standards.

- Regular monitoring and reporting: Implement a comprehensive monitoring program to track key parameters and ensure compliance.

- Maintenance and calibration: Regularly maintain and calibrate all filtration equipment to ensure optimal performance.

- Waste management: Develop and implement a proper waste management plan for handling and disposing of filter backwash and sludge.

- Collaboration with regulators: Establish open communication with regulatory agencies to stay informed about changes and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Filtration Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Filtration Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Filtration Supervisor is responsible for overseeing the operation and maintenance of filtration systems, ensuring that they meet the required standards and specifications. Their duties include:

1. Supervising and Managing Team

Directing, coordinating, and motivating a team of filtration technicians, operators, and other staff

- Setting and communicating clear goals and objectives.

- Providing guidance, training, and support to team members.

2. Optimizing Filtration Processes

Monitoring and evaluating filtration processes to identify areas for improvement and optimization.

- Conducting regular inspections and audits to ensure compliance with standards and regulations.

- Implementing and managing quality control procedures to maintain product quality.

3. Maintaining Equipment and Infrastructure

Ensuring that filtration systems are maintained in optimal condition to minimize downtime.

- Scheduling and coordinating maintenance activities.

- Troubleshooting and resolving equipment malfunctions.

4. Ensuring Compliance and Safety

Ensuring compliance with all applicable environmental regulations and safety standards.

- Implementing and monitoring safety protocols and procedures.

- Conducting regular training and safety audits.

Interview Tips

Preparing for an interview for a Filtration Supervisor position requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace your interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, products or services, and the specific responsibilities of the Filtration Supervisor role. This will help you understand the company’s culture and the expectations of the position.

- Visit the company’s website and social media pages.

- Read industry publications and articles about filtration systems.

2. Practice Answering Common Interview Questions

Prepare answers to common interview questions related to your technical skills, experience, and leadership abilities. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples.

- Describe a time when you successfully optimized a filtration process.

- Provide an example of how you handled a challenging situation with a team member.

3. Highlight Your Technical Expertise

Showcase your in-depth knowledge of filtration systems and technologies. Discuss your experience with different types of filtration equipment, such as membrane filters, activated carbon filters, and HEPA filters.

- Explain the principles of various filtration mechanisms.

- Discuss the advantages and disadvantages of different filtration methods.

4. Emphasize Your Leadership Skills

Highlight your ability to lead and motivate a team. Provide examples of how you have successfully managed and developed employees. Discuss your experience in setting goals, delegating tasks, and providing feedback.

- Describe a time when you successfully implemented a new training program for your team.

- Provide an example of how you resolved a conflict between team members.

5. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview. Be enthusiastic about the opportunity and demonstrate your interest in the role and the company. Remember to ask thoughtful questions and show that you are genuinely interested in the position.

- Prepare a few questions to ask the interviewer about the company and the role.

- Express your appreciation for the interview opportunity and follow up with a thank-you note.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Filtration Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.