Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Final Armature Tester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

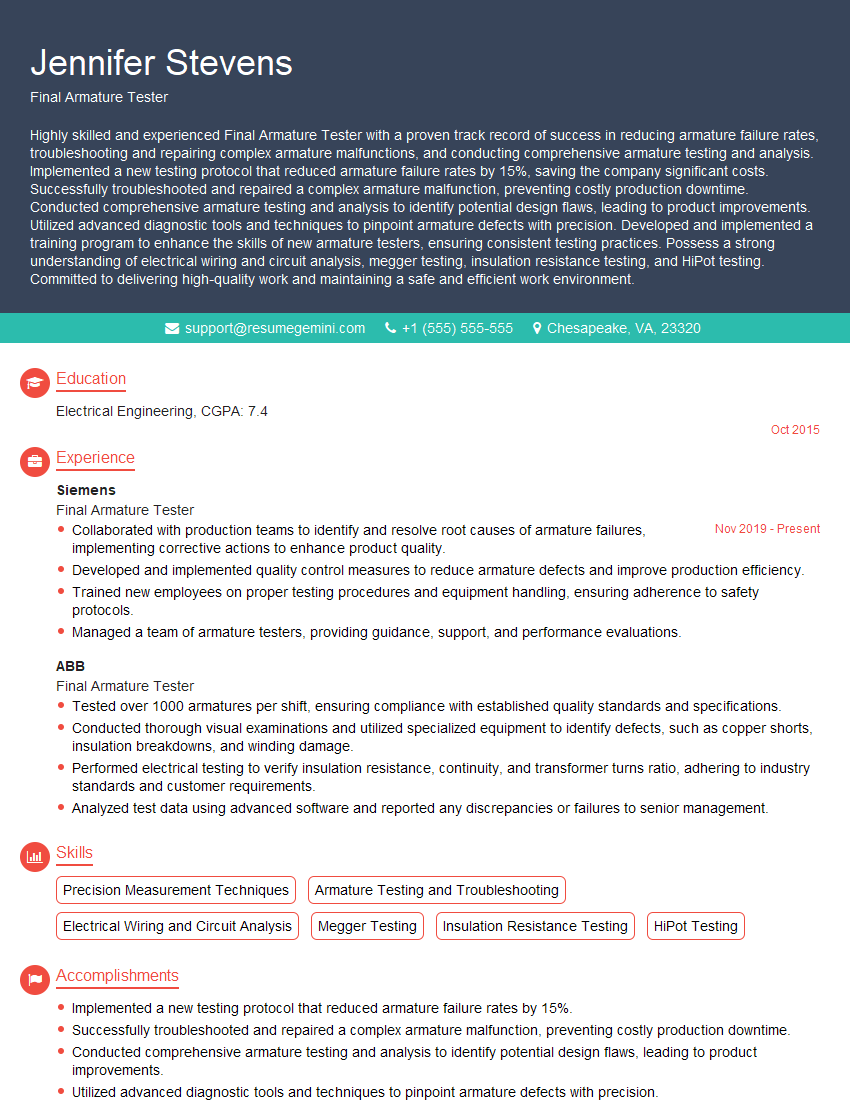

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Final Armature Tester

1. What is the purpose of testing an armature?

The purpose of testing an armature is to ensure that it meets the required specifications and is free from any defects that could affect the performance of the motor or generator.

2. What are the different types of armature tests that can be performed?

Hipot Test

- Insulation resistance test

- Dielectric strength test

Continuity Test

- Resistance measurement

- Continuity check between windings

3. What are the safety precautions that must be taken when performing armature tests?

The following safety precautions must be taken when performing armature tests:

- Wear appropriate safety gear, including gloves, safety glasses, and a lab coat.

- Ensure that the armature is properly grounded.

- Do not touch the armature while it is energized.

- Use caution when handling high-voltage equipment.

4. What are the common defects that can be detected during armature testing?

The common defects that can be detected during armature testing include:

- Open windings

- Short circuits

- Ground faults

- Insulation failures

- Mechanical damage

5. What is the importance of maintaining proper records of armature tests?

Maintaining proper records of armature tests is important for the following reasons:

- To track the history of the armature and identify any potential problems.

- To ensure that the armature meets the required specifications.

- To provide documentation for quality control purposes.

6. What are the different types of armature testing equipment?

The different types of armature testing equipment include:

- Hipot testers

- Continuity testers

- Insulation resistance testers

- Dielectric strength testers

- Megohmmeters

7. What are the steps involved in performing a hipot test on an armature?

The steps involved in performing a hipot test on an armature are as follows:

- Connect the armature to the hipot tester.

- Set the test voltage and duration.

- Apply the test voltage to the armature.

- Monitor the armature for any signs of insulation failure.

8. What are the steps involved in performing a continuity test on an armature?

The steps involved in performing a continuity test on an armature are as follows:

- Connect the armature to the continuity tester.

- Set the test current and duration.

- Apply the test current to the armature.

- Measure the resistance between the windings.

- Check for any open windings or short circuits.

9. What are the steps involved in performing an insulation resistance test on an armature?

The steps involved in performing an insulation resistance test on an armature are as follows:

- Connect the armature to the insulation resistance tester.

- Set the test voltage and duration.

- Apply the test voltage to the armature.

- Measure the insulation resistance between the windings and the frame.

- Check for any insulation failures.

10. What are the steps involved in performing a dielectric strength test on an armature?

The steps involved in performing a dielectric strength test on an armature are as follows:

- Connect the armature to the dielectric strength tester.

- Set the test voltage and duration.

- Apply the test voltage to the armature.

- Monitor the armature for any signs of insulation failure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Final Armature Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Final Armature Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Final Armature Tester holds a crucial role in ensuring the optimal performance and reliability of electrical equipment. Their responsibilities encompass a wide range of tasks, including:

1. Armature Testing

Utilizing specialized equipment, the Armature Tester conducts thorough inspections of armature windings and insulation systems. They meticulously examine components for defects, shorts, grounds, and other irregularities that may compromise performance.

- Carry out insulation resistance, voltage breakdown, and continuity tests.

- Detect and rectify issues in windings, such as open circuits, shorts, and grounds.

2. Test Equipment Calibration

The accuracy and reliability of test results rely heavily on the precise calibration of equipment. The Armature Tester is tasked with the critical responsibility of calibrating all test equipment according to established industry standards.

- Adhere to calibration schedules, ensuring equipment meets accuracy specifications.

- Utilize calibration tools and techniques to adjust and fine-tune equipment parameters.

3. Data Analysis and Troubleshooting

After meticulously conducting tests, the Armature Tester carefully analyzes the collected data to identify any anomalies or areas of concern. Based on their expert analysis, they devise effective troubleshooting strategies to rectify issues and optimize performance.

- Interpret test results and diagnose potential problems with armature and insulation.

- Implement troubleshooting procedures, utilizing repair techniques and replacing faulty components as necessary.

4. Quality Assurance

The Final Armature Tester serves as a guardian of quality, ensuring that electrical equipment meets stringent performance and safety standards. They actively participate in quality control processes, adhering to documented procedures and industry regulations.

- Collaborate with other departments, providing feedback on production processes and quality improvement initiatives.

- Maintain detailed records and documentation of test results and repairs, ensuring traceability and accountability.

Interview Tips

To excel in the Final Armature Tester interview, candidates should meticulously prepare by honing their technical skills and refining their presentation abilities:

1. Technical Proficiency

A deep understanding of armature testing principles, electrical theory, and industry standards is paramount. Candidates should be well-versed in various test methods, equipment calibration procedures, and troubleshooting techniques.

- Study technical manuals and industry publications to expand your knowledge base.

- Familiarize yourself with common armature defects and troubleshooting methodologies.

2. Communication Skills

Clear and concise communication is essential for effectively conveying test results, troubleshooting strategies, and quality recommendations. Candidates should demonstrate strong verbal and written communication skills.

- Develop the ability to articulate technical concepts in a comprehensible manner.

- Practice presenting and discussing your findings with confidence and clarity.

3. Attention to Detail

Final Armature Testers must possess a meticulous eye for detail, as their work hinges on precise measurements and accurate data analysis. Candidates should emphasize their ability to identify and interpret subtle variations in test results.

- Showcase your meticulousness by highlighting examples of your attention to detail in previous roles.

- Prepare for questions that assess your ability to detect and rectify defects.

4. Problem-Solving Ability

Troubleshooting electrical issues requires analytical thinking and problem-solving skills. Candidates should demonstrate their ability to diagnose and resolve complex problems, and present logical solutions.

- Emphasize your problem-solving capabilities by providing examples of troubleshooting experiences.

- Prepare for scenario-based questions that test your ability to analyze and resolve armature-related issues.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Final Armature Tester role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.