Are you gearing up for a career in Final Assembly Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Final Assembly Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

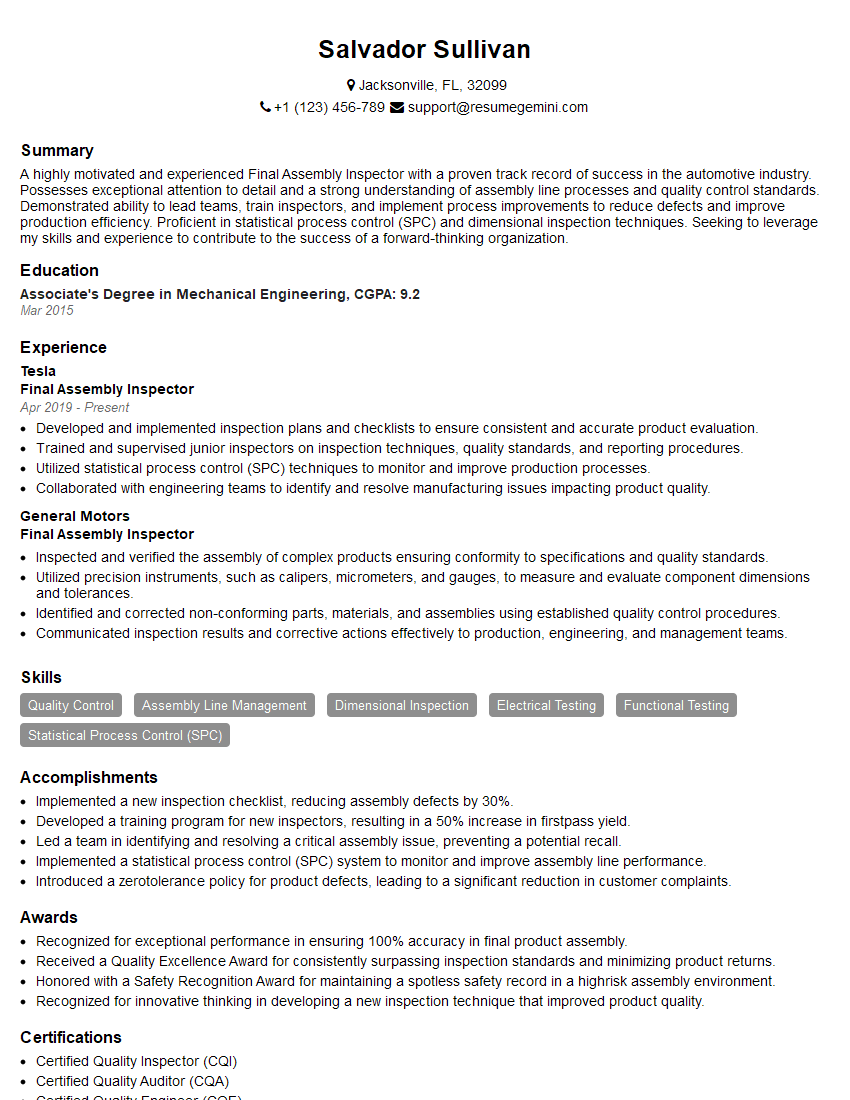

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Final Assembly Inspector

1. What are the key responsibilities of a Final Assembly Inspector?

As a Final Assembly Inspector, my primary responsibilities would include:

- Inspecting and verifying the quality of fully assembled products.

- Ensuring that products meet all specifications and industry standards.

- Identifying and documenting defects or non-conformities.

- Providing feedback to the production team to improve assembly processes.

- Maintaining a clean and organized work area.

2. What types of inspection techniques do you use in your work?

Visual Inspection

- Closely examining products for defects, such as scratches, dents, or misalignments.

- Using magnifying glasses or microscopes to inspect fine details.

- Comparing products to standard specifications or blueprints.

Functional Testing

- Testing products to ensure they operate properly and meet performance requirements.

- Using specialized equipment or software to perform functional tests.

Dimensional Inspection

- Measuring products to ensure they meet specified dimensions.

- Using calipers, micrometers, and other measuring instruments.

3. How do you handle products that do not meet specifications?

Upon identifying non-conforming products, I follow these steps:

- Isolate the defective products and tag them clearly.

- Document the defects and take photographs as evidence.

- Notify the production team and discuss the issue.

- Work with the team to determine the root cause of the defects.

- Support the implementation of corrective actions to prevent similar issues in the future.

4. What are some of the challenges you have faced in your previous role as a Final Assembly Inspector?

One of the main challenges I encountered was identifying defects in complex assemblies with multiple components. I overcame this by thoroughly understanding the assembly process and using various inspection techniques.

Another challenge was dealing with high-volume production lines. To ensure efficiency, I developed a systematic inspection process and prioritized the critical areas for inspection.

5. How do you stay up-to-date with advancements in inspection technologies and best practices?

To stay current, I regularly attend industry conferences and workshops.

I also subscribe to relevant trade publications and participate in online forums to connect with other professionals in the field.

Additionally, I seek out opportunities to collaborate with manufacturers and suppliers to learn about new technologies and best practices.

6. What are some of the quality standards that you are familiar with?

- ISO 9001:2015

- AS9100

- MIL-STD-105

- IPC-A-610

7. What is your approach to ensuring accuracy and consistency in your inspections?

To ensure accuracy, I:

- Follow established inspection procedures and checklists.

- Calibrate inspection equipment regularly.

- Take measurements and document results precisely.

- Double-check my work and seek a second opinion when necessary.

To maintain consistency, I:

- Use standardized inspection methods and criteria.

- Provide detailed training to new inspectors.

- Conduct regular audits to ensure adherence to established standards.

8. How do you cope with pressure and meet deadlines in a fast-paced production environment?

In a fast-paced production environment, I manage pressure and meet deadlines by:

- Prioritizing and organizing my tasks effectively.

- Working efficiently and avoiding distractions.

- Communicating regularly with the production team to stay informed of any changes or adjustments.

- Seeking support and delegating tasks when necessary.

- Maintaining a calm and focused mindset under pressure.

9. What is your understanding of statistical process control (SPC) and how do you apply it in your work?

Statistical process control (SPC) involves using statistical methods to monitor and control production processes. I apply SPC in my work by:

- Collecting and analyzing data on product quality.

- Creating control charts to track performance and identify trends.

- Using statistical techniques to determine when a process is out of control.

- Implementing corrective actions to improve process stability and product quality.

10. How do you support the continuous improvement of inspection processes?

I contribute to continuous improvement by:

- Identifying areas for improvement in current inspection processes.

- Proposing and implementing new or revised inspection techniques.

- Providing feedback on the effectiveness of inspection methods.

- Participating in team discussions on quality improvement initiatives.

- Staying informed about emerging technologies and best practices in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Final Assembly Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Final Assembly Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Final Assembly Inspectors are accountable for ensuring the final assembly of products meet quality standards and customer specifications. Their core responsibilities involve:

1. Quality Inspection

Inspecting assembled products thoroughly to identify defects or non-conformities in materials, components, and workmanship.

- Using a variety of inspection tools and techniques to assess product quality, including visual inspections, dimensional measurements, and functional testing.

- Identifying and documenting any deviations from established specifications, standards, or customer requirements.

2. Functional Testing

Conducting functional tests to verify the proper operation and performance of assembled products.

- Operating products according to specified procedures to evaluate their functionality, safety, and adherence to design specifications.

- Troubleshooting and resolving any functional issues identified during testing.

3. Documentation and Reporting

Maintaining accurate records of inspection results and product defects.

- Preparing and submitting inspection reports that detail identified defects, corrective actions taken, and recommendations for improvement.

- Communicating inspection findings to relevant personnel, including production staff, quality control, and management.

4. Process Improvement

Identifying areas for process improvement and implementing changes to enhance product quality and efficiency.

- Analyzing inspection data to identify recurring defects and patterns that indicate potential process issues.

- Working with production and engineering teams to develop and implement corrective measures to prevent future defects.

Interview Tips

To ace the interview for a Final Assembly Inspector position, it’s essential to demonstrate your technical skills, attention to detail, and commitment to quality.

1. Research the Company and Role

Thoroughly research the company and the specific role you’re applying for. Understand their product line, quality standards, and expectations for Final Assembly Inspectors.

- Review the company website, industry publications, and social media pages.

- Identify key responsibilities and requirements for the position and match your qualifications accordingly.

- Example: “I understand that your company places great emphasis on product quality. In my previous role, I implemented a rigorous inspection process that reduced product defects by 20%.”

2. Highlight Your Technical Skills

Emphasize your proficiency in inspection techniques, quality control principles, and familiarity with relevant industry standards.

- Demonstrate your expertise in visual inspections, dimensional measurements, and functional testing.

- Mention any certifications or training programs you have completed in these areas.

- Example: “I am certified in ISO 9001:2015 and have extensive experience in conducting thorough inspections and testing of electronic assemblies.”

3. Showcase Your Attention to Detail

Convey your meticulous nature and ability to identify even the smallest defects. Provide examples of situations where your attention to detail made a significant difference.

- Describe a time when you detected a minor but critical defect that others had overlooked.

- Emphasize your ability to follow instructions precisely and maintain high levels of accuracy.

- Example: “In my last role, I developed a detailed checklist for final assembly inspections, ensuring that every product met our exacting standards.”

4. Emphasize Your Commitment to Quality

Express your passion for quality and your dedication to delivering products that meet or exceed customer expectations.

- Share your understanding of the importance of quality in manufacturing and its impact on customer satisfaction.

- Discuss your willingness to go the extra mile to ensure product excellence.

- Example: “I believe that every product should be of the highest quality. I am committed to upholding rigorous standards and working collaboratively with my team to continuously improve our processes.”

5. Practice Your Communication Skills

Effective communication is crucial for Final Assembly Inspectors. Practice articulating your findings, collaborating with colleagues, and reporting your results clearly and concisely.

- Prepare for questions about your ability to communicate with production and engineering teams.

- Mention any experience or training you have in written and verbal communication.

- Example: “I have a proven ability to communicate technical information effectively to both technical and non-technical audiences. I am comfortable communicating my findings and recommendations to management and production staff.”

Next Step:

Now that you’re armed with the knowledge of Final Assembly Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Final Assembly Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini