Feeling lost in a sea of interview questions? Landed that dream interview for Final Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Final Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

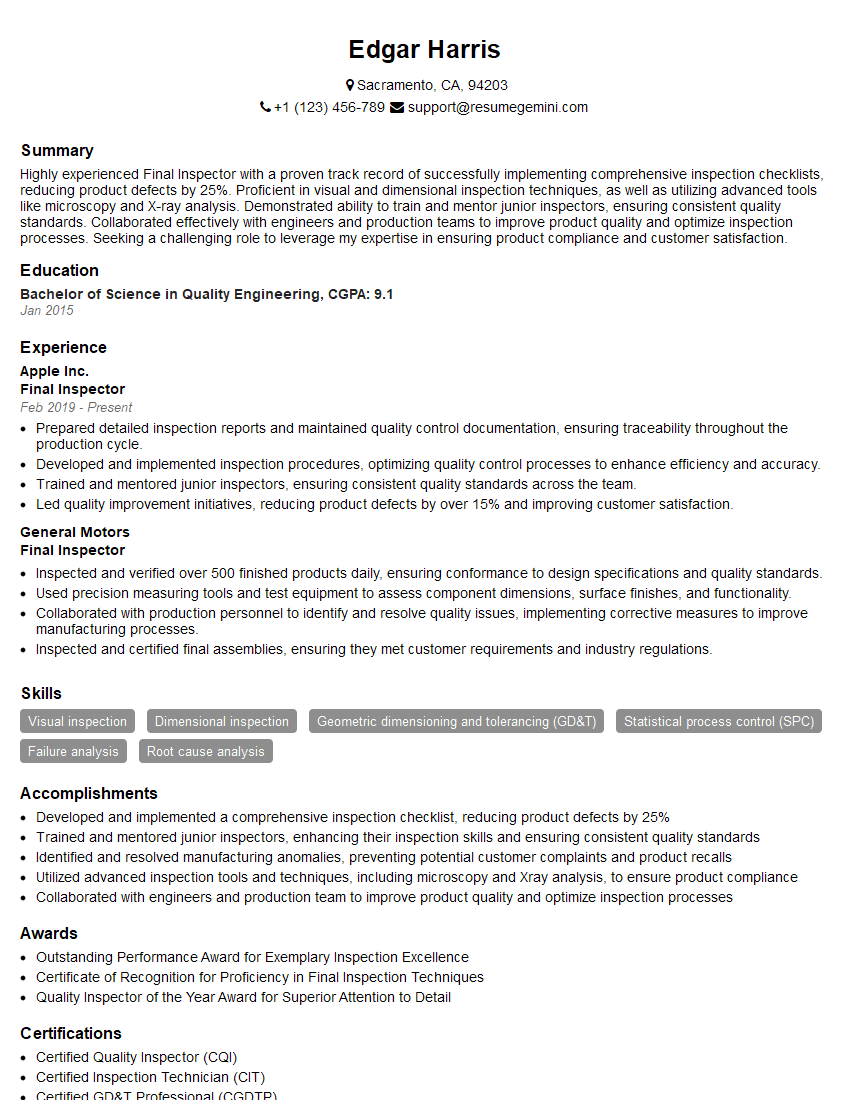

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Final Inspector

1. Define the primary responsibilities of a Final Inspector?

As a Final Inspector, my key responsibilities would include:

- Conducting thorough inspections of finished products to ensure they meet all specifications and quality standards.

- Evaluating products for defects, such as dimensional inaccuracies, surface blemishes, or functional issues.

- Utilizing measuring instruments and inspection equipment to verify product dimensions, tolerances, and other critical characteristics.

- Documenting inspection results, identifying non-conformances, and initiating corrective actions as necessary.

- Maintaining a clean and organized work area, ensuring that inspection equipment is properly calibrated and maintained.

2. Explain the importance of attention to detail in final inspection?

Role in Quality Assurance

- Attention to detail in final inspection plays a crucial role in ensuring product quality and customer satisfaction.

- By meticulously inspecting each item, inspectors can identify and eliminate defects that could compromise product performance or safety.

Cost Reduction and Efficiency

- Thorough final inspections help prevent defective products from reaching customers, reducing the risk of costly recalls or warranty claims.

- Early detection of defects allows for timely corrective actions, minimizing production downtime and waste.

Compliance and Reputation

- Attention to detail ensures that products meet regulatory standards and industry specifications.

- Consistent high-quality output builds customer trust and enhances the company’s reputation for reliability.

3. Describe the steps involved in a comprehensive final inspection process.

A comprehensive final inspection process typically involves the following steps:

- Visual Inspection: Examine products for surface defects, scratches, dents, or any other visible imperfections.

- Dimensional Inspection: Use measuring instruments to verify product dimensions, ensuring they meet specifications and tolerances.

- Functional Testing: Test products to ensure they operate correctly, verifying their performance and functionality.

- Documentation: Record inspection results, including any non-conformances or defects, and initiate corrective actions.

- Corrective Actions: Implement measures to address any identified defects or non-conformances, ensuring product quality.

- Final Approval: Approve products that meet all inspection criteria, releasing them for packaging and distribution.

4. What types of inspection equipment are commonly used in final inspection?

- Measuring Instruments: Calipers, micrometers, height gauges, etc.

- Dimensional Inspection Equipment: CMMs, laser scanners, etc.

- Functional Test Equipment: Load testers, electrical testers, etc.

- Vision Inspection Systems: Cameras and software for automated defect detection.

- Non-Destructive Testing Equipment: Ultrasonic testing, radiography, etc.

5. How do you prioritize inspection tasks when faced with multiple production lines or a high volume of products?

Prioritizing inspection tasks effectively is crucial to ensure efficient and timely product delivery. I would approach this by:

- Understanding Product Criticality: Identifying products with higher safety or quality risks that require immediate attention.

- Analyzing Production Schedules: Assessing upcoming deadlines and adjusting inspection schedules accordingly.

- Coordinating with Production Team: Communicating with production personnel to understand their priorities and any urgent requests.

- Optimizing Inspection Process: Streamlining inspection procedures to maximize efficiency without compromising quality.

- Utilizing Technology: Employing automated inspection systems or data analytics tools to enhance productivity.

6. How do you handle situations where you identify non-conformances or defects during final inspection?

Upon identifying non-conformances or defects, I would follow a systematic process to ensure prompt and effective resolution:

- Document the Issue: Clearly record the details of the defect, including its nature, location, and severity.

- Communicate with Relevant Parties: Inform supervisors, engineers, and production personnel about the non-conformance.

- Initiate Corrective Actions: Work with the team to identify the root cause and implement corrective measures to prevent recurrence.

- Isolate Affected Products: Segregate defective products to prevent their release into the market.

- Follow-Up and Inspection: Conduct follow-up inspections to verify the effectiveness of corrective actions.

7. How do you stay up-to-date on industry best practices and advancements in inspection techniques?

To remain proficient in my role, I actively engage in continuous learning and professional development:

- Attending Conferences and Workshops: Participating in industry events to learn about new technologies and best practices.

- Reading Technical Publications: Subscribing to journals, white papers, and industry magazines for up-to-date information.

- Networking with Peers: Connecting with other quality professionals to exchange knowledge and insights.

- Online Courses and Certifications: Pursuing online courses or certifications to enhance my technical skills.

- Collaboration with Suppliers and Vendors: Seeking information on the latest inspection equipment and methods from industry experts.

8. Describe a situation where you identified a potential quality issue during final inspection and how you resolved it.

In a previous role, I encountered a situation where I identified a recurring surface defect on a high-volume product. I:

- Documented the Defect: Photographed and described the defect in detail for further analysis.

- Communicated with Production Team: Notified the production supervisor and engineers about the issue.

- Collaborated on Root Cause Analysis: Worked with the team to determine the cause of the defect, which was traced to a faulty machine.

- Implemented Corrective Action: Coordinated with maintenance to repair the machine and adjust production parameters.

- Verified Resolution: Conducted follow-up inspections to ensure the corrective actions were effective and the defect was eliminated.

9. How do you ensure the accuracy and reliability of your inspection results?

- Proper Equipment Calibration: Regularly calibrate all measuring instruments and inspection equipment to maintain precision.

- Established Inspection Procedures: Follow standardized inspection protocols to minimize human error and ensure consistency.

- Thorough Inspection: Conduct thorough visual and dimensional inspections, paying attention to all critical product features.

- Record Keeping: Document inspection results thoroughly and accurately, providing supporting evidence for my findings.

- Self-Assessment: Regularly review my own inspection techniques to identify areas for improvement.

10. What are the key qualities and skills required to be an effective Final Inspector?

- Attention to Detail: Meticulous and thorough in examining products for defects and non-conformances.

- Technical Skills: Proficiency in using measuring instruments, inspection equipment, and understanding product specifications.

- Problem-Solving Abilities: Able to identify issues, determine root causes, and implement corrective actions.

- Communication Skills: Effectively communicate inspection results, collaborate with team members, and document findings.

- Quality Mindset: Passionate about ensuring product quality and maintaining high standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Final Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Final Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Final Inspectors are responsible for ensuring that products meet quality standards before they are shipped to customers. They perform a variety of tasks, including:1. Verify product specifications

Final Inspectors ensure that the quality of products meets specifications. They check products for defects, damage, and other issues. This may involve using measuring tools, gauges, and other equipment.

2. Inspect products

Inspectors examine products thoroughly and identify any defects or quality issues. They may use a variety of tools and equipment, such as microscopes and gauges, to ensure that the products meet quality standards.

3. Document inspections

Inspectors document their findings in a report, including any defects or quality issues they identify. They may also provide recommendations for corrective actions to ensure that future products meet quality standards.

4. Train and supervise other employees

Inspectors may train and supervise other employees in quality control procedures. They may also provide guidance on how to identify and resolve quality issues.

5. Maintain inspection records

Inspectors maintain inspection records, including reports, checklists, and other documents, to ensure that products meet quality standards.

6. Adhere to industry standards

Inspectors adhere to industry standards and regulations related to quality control. They may be required to obtain certification or training in quality control.

7. Manage quality control processes

Inspectors manage quality control processes, including developing and implementing quality control procedures. They may also work with other departments to ensure that quality standards are met.

Interview Tips

To help candidates ace the interview for a Final Inspector position, here are some tips:1. Prepare for technical questions

Candidates should be prepared to answer questions about their technical skills and knowledge of quality control processes. They should be able to demonstrate their understanding of industry standards and regulations.

2. Showcase your attention to detail

Inspectors must have a keen eye for detail and be able to identify even the smallest defects. Candidates should highlight their attention to detail in their resume and cover letter.

3. Emphasize your communication skills

Inspectors must be able to communicate effectively with colleagues, supervisors, and customers. Candidates should emphasize their communication skills in their resume and cover letter.

4. Prepare examples of your work

Candidates may be asked to provide examples of their work, such as inspection reports or quality control procedures. They should be prepared to discuss their work in detail and explain how they ensure product quality.

5. Dress professionally

Candidates should dress professionally for the interview. This shows that they are serious about the position and respect the interviewer’s time.

Next Step:

Now that you’re armed with the knowledge of Final Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Final Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini