Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Finish Grinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

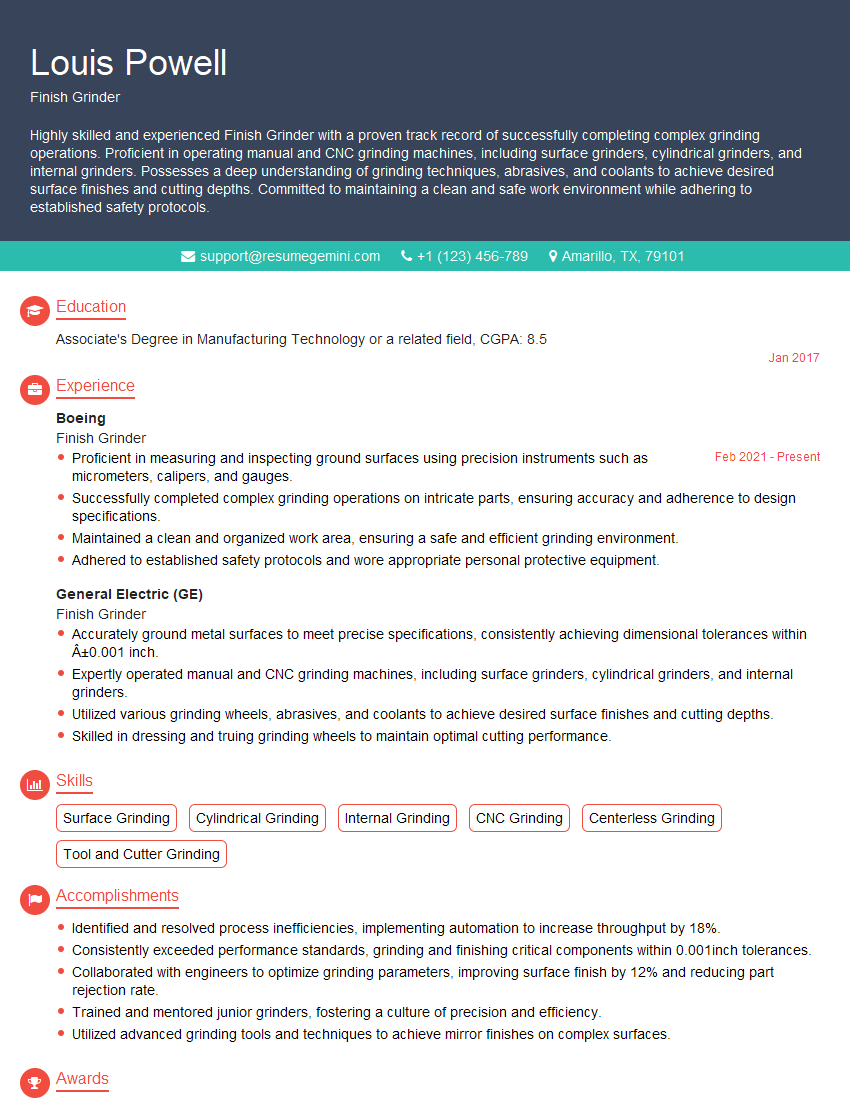

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Finish Grinder

1. Describe the process of finish grinding a workpiece?

- Prepare the workpiece by ensuring it is clean and free of any burrs or imperfections.

- Select the appropriate grinding wheel and mount it on the machine.

- Consider factors such as the material of the workpiece, the desired surface finish, and the grinding method.

- Dress the grinding wheel using a dressing tool to ensure a sharp and even surface.

- Securely mount the workpiece on the grinding machine and adjust the table for proper positioning.

- Start the grinding process and apply the workpiece to the grinding wheel with consistent pressure.

- Monitor the grinding progress and make any necessary adjustments to the machine or grinding parameters.

- Clean and deburr the workpiece after grinding to remove any remaining material or sharp edges.

2. What are the different types of abrasives used in finish grinding?

Natural Abrasives

- Diamond

- Corundum (aluminum oxide)

- Silicon carbide

Synthetic Abrasives

- Cubic boron nitride (CBN)

- Fused aluminum oxide

- Sol-gel alumina

3. How do you determine the correct grinding wheel grit size for finish grinding?

- Consider the material being ground and its hardness.

- Finer grit sizes (higher numbers) produce smoother surface finishes.

- Coarser grit sizes (lower numbers) are used for faster stock removal.

- Refer to the manufacturer’s recommendations or consult with a grinding expert.

4. What are the different grinding methods used in finish grinding?

- Surface grinding: Uses a flat grinding wheel to create precise flat surfaces.

- Cylindrical grinding: Uses a cylindrical grinding wheel to grind cylindrical surfaces.

- Internal grinding: Uses a smaller grinding wheel to grind the inside surfaces of holes or bores.

- Centerless grinding: Uses two grinding wheels to grind cylindrical workpieces without the need for centers.

5. How do you ensure the accuracy and precision of finish grinding operations?

- Use high-quality grinding machines with precise controls.

- Calibrate and maintain grinding machines regularly.

- Use precision measuring tools to monitor and adjust grinding parameters.

- Follow established grinding procedures and techniques.

- Monitor the grinding process closely to identify and correct any errors or deviations.

6. What are the common challenges encountered in finish grinding and how do you overcome them?

Challenges

- Surface defects, such as scratches or burns.

- Dimensional inaccuracies.

- Excessive heat generation.

Solutions

- Use sharp and properly dressed grinding wheels.

- Apply appropriate grinding fluids to reduce heat and lubricate the process.

- Adjust grinding parameters, such as speed, feed, and depth of cut.

- Use precision measuring tools to monitor and correct deviations.

7. How do you maintain and troubleshoot finish grinding equipment?

Maintenance

- Regularly clean and lubricate grinding machines.

- Inspect and replace worn or damaged components, such as bearings and seals.

- Calibrate and adjust grinding machines as needed.

Troubleshooting

- Identify the source of the problem by observing machine behavior and workpiece quality.

- Check for common issues, such as dull grinding wheels, improper workpiece setup, or incorrect grinding parameters.

- Refer to manufacturer’s manuals or seek assistance from qualified technicians.

8. What are the safety precautions that must be taken when operating finish grinding equipment?

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs.

- Ensure proper ventilation to remove grinding dust and fumes.

- Keep the work area clean and free of tripping hazards.

- Follow established safety protocols and procedures.

- Be aware of the machine’s moving parts and potential pinch points.

9. How do you stay updated on the latest advances and techniques in finish grinding?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Participate in online forums and discussion groups.

- Consult with grinding equipment manufacturers and experts.

- Seek continuing education opportunities.

10. How do you handle high-tolerance and critical finish grinding jobs?

- Pay meticulous attention to detail and follow established processes.

- Use high-precision equipment and tools.

- Monitor grinding parameters closely and make necessary adjustments.

- Implement quality control measures to ensure accuracy and precision.

- Work closely with engineers and quality assurance personnel.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Finish Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Finish Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Finish Grinder is responsible for operating a grinding machine to smooth and polish the surfaces of metal components. They ensure that the finished products meet the required specifications, and they work closely with other team members to produce high-quality products.

1. Set up and operate grinding machines

The Finish Grinder is responsible for setting up and operating grinding machines. This includes selecting the appropriate grinding wheels, setting the correct speeds and feeds, and loading and unloading workpieces.

- Select the appropriate grinding wheels based on the material being ground, the desired finish, and the size and shape of the workpiece.

- Set the correct speeds and feeds to ensure that the grinding process is efficient and produces the desired results.

- Load and unload workpieces into and out of the grinding machine, using proper safety procedures.

2. Inspect finished products

The Finish Grinder is responsible for inspecting finished products to ensure that they meet the required specifications. This includes checking the surface finish, dimensions, and tolerances.

- Visually inspect finished products to identify any defects, such as scratches, nicks, or burrs.

- Use measuring tools, such as micrometers and calipers, to verify that the dimensions and tolerances of the finished products meet the required specifications.

- Report any defects or non-conforming products to the supervisor.

3. Maintain grinding machines

The Finish Grinder is responsible for maintaining grinding machines to ensure that they are operating properly and safely. This includes cleaning and lubricating the machines, and replacing worn or damaged parts.

- Clean and lubricate grinding machines according to the manufacturer’s instructions.

- Inspect grinding machines for worn or damaged parts, and replace them as necessary.

- Report any maintenance issues to the supervisor.

4. Work with other team members

The Finish Grinder works closely with other team members to produce high-quality products. This includes communicating with engineers, machinists, and quality control personnel.

- Communicate with engineers to understand the design specifications for the finished products.

- Work with machinists to ensure that the workpieces are properly prepared for grinding.

- Collaborate with quality control personnel to ensure that the finished products meet the required specifications.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Finish Grinder position:

Before the Interview

- Research the company and the position. This will help you understand the company’s culture and the specific requirements of the job.

- Practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Dress professionally and arrive on time for your interview. First impressions matter, so make sure you put your best foot forward.

During the Interview

- Be yourself and be honest. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be enthusiastic and positive. The interviewer wants to see that you’re excited about the opportunity to work for their company.

- Listen carefully to the interviewer’s questions and answer them thoughtfully and concisely.

- Ask questions of your own. This shows that you’re interested in the position and the company.

After the Interview

- Send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and consideration.

- Follow up with the interviewer if you don’t hear back within a week or two. This shows that you’re still interested in the position and that you’re willing to take the initiative.

- Be patient. The hiring process can take time, so don’t get discouraged if you don’t get an offer right away.

Following these tips will help you increase your chances of success in your interview for a Finish Grinder position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Finish Grinder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Finish Grinder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.