Are you gearing up for a career in Finished Stock Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Finished Stock Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

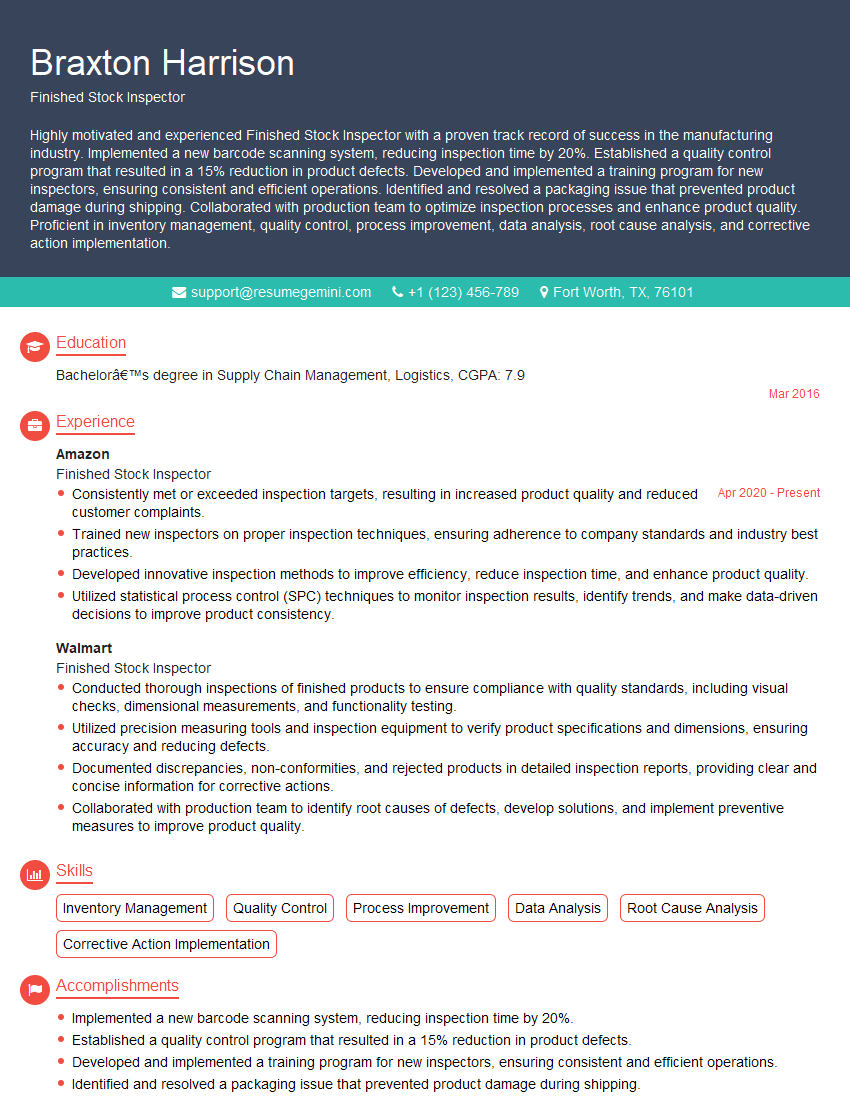

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Finished Stock Inspector

1. What are the key responsibilities of a Finished Stock Inspector?

As a Finished Stock Inspector, I am responsible for:

- Inspecting and verifying finished products for defects in accordance with quality standards and specifications

- Measuring product dimensions and tolerances using precision instruments to ensure they meet specifications

- Identifying and documenting any non-conforming or defective products and taking appropriate corrective actions

- Maintaining accurate records and documentation on all inspection activities and reporting any quality-related issues

- Collaborating with production team to identify and resolve manufacturing issues affecting product quality

2. What are the different types of inspections you conduct as a Finished Stock Inspector?

Incoming Inspection

- Verifying the quality and quantity of incoming raw materials and components

- Inspecting packaging for any damage or defects

- Cross-referencing against purchase orders and specifications

In-Process Inspection

- Monitoring production processes to detect potential defects

- Inspecting products at various stages of manufacturing

- Providing feedback to production team on areas for improvement

Final Inspection

- Thoroughly inspecting finished products before they are shipped to customers

- Ensuring product functionality, appearance, and compliance with specifications

- Inspecting product packaging and labeling for accuracy and completeness

3. How do you prioritize inspection tasks when faced with multiple production lines and high volume?

- Assess the urgency of each production line based on customer demand and delivery schedules

- Focus on inspecting critical components and products with high failure rates

- Use historical data and statistical process control to identify potential quality issues

- Work closely with supervisors and production managers to determine the most efficient inspection schedule

- Delegate tasks to ensure timely and effective inspection of all products

4. What is your approach to handling non-conforming materials?

- Segregate non-conforming materials and tag them for identification

- Document the type and severity of the defects

- Determine the root cause of the defects and work with production team to implement corrective actions

- Decide whether the materials can be reworked or need to be scrapped

- Follow up with production to ensure corrective actions are effective and prevent recurrence of defects

5. How do you communicate inspection findings and ensure corrective actions are taken?

- Create detailed inspection reports and communicate them to production supervisors and managers

- Discuss inspection results and identify areas for improvement with the production team

- Participate in quality improvement meetings to provide insights and support

- Follow up with production team to ensure corrective actions are implemented within agreed-upon timelines

- Monitor the effectiveness of corrective actions and provide feedback to management

6. What is your experience with using quality control software and inspection tools?

- Proficient in using inspection software to manage inspections, record data, and generate reports

- Experienced in using precision measuring instruments such as calipers, micrometers, and gauges

- Familiar with statistical process control techniques and quality control methodologies

- Knowledge of industry-specific quality standards and regulations

- Ability to interpret technical drawings and specifications

7. How do you stay up-to-date with the latest quality control techniques and industry best practices?

- Attend industry conferences and seminars

- Read trade publications and technical articles

- Participate in online forums and webinars

- Receive training from manufacturers and suppliers on new inspection techniques and equipment

- Network with other quality control professionals

8. How do you handle pressure and work effectively in a fast-paced manufacturing environment?

- Maintain composure and prioritize tasks even during periods of high demand

- Use effective time management skills to meet deadlines without compromising accuracy

- Communicate clearly and effectively with team members to ensure smooth workflow

- Stay organized and maintain a clean and efficient work area

- Take breaks and engage in stress-reducing activities to maintain focus and productivity

9. What motivates you to succeed in the role of Finished Stock Inspector?

- Passion for ensuring product quality and customer satisfaction

- Attention to detail and a commitment to accuracy

- Desire to contribute to the company’s success through effective inspection practices

- Enjoyment of working in a fast-paced and results-oriented environment

- Opportunity to make a meaningful impact on the safety and quality of manufactured products

10. Do you have any questions for me about the role or the company?

I am eager to learn more about the specific responsibilities and expectations for this position within your organization. Additionally, I would appreciate insights into the company’s quality control culture and its commitment to continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Finished Stock Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Finished Stock Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Finished Stock Inspectors play a crucial role in ensuring the quality and accuracy of finished products.

1. Inspect and Verify Products

Meticulously examine finished products to ensure they meet specified standards and specifications.

- Check for defects, damages, and other discrepancies.

- Verify product quantities, dimensions, and packaging.

2. Document Inspections

Maintain accurate records of inspections conducted, including details of any defects or discrepancies found.

- Prepare inspection reports and submit them to supervisors.

- Track and analyze inspection data to identify trends and improve processes.

3. Quality Control

Adhere to established quality control procedures and ensure compliance with industry standards.

- Inspect raw materials and components to prevent defects.

- Monitor production processes to identify potential issues.

4. Collaboration and Communication

Effectively communicate with production staff, supervisors, and customers to resolve issues and ensure timely delivery of quality products.

- Provide feedback to production teams to improve product quality.

- Respond to customer inquiries and address concerns promptly.

Interview Preparation Tips

To ace the interview for a Finished Stock Inspector position, consider the following preparation tips:

1. Research the Company and Industry

Thoroughly research the company’s products, services, and quality standards.

- Visit the company website and read industry publications.

- Stay up-to-date on the latest industry trends and best practices.

2. Highlight Relevant Skills and Experience

Emphasize your attention to detail, ability to follow instructions, and problem-solving skills.

- Quantify your accomplishments and provide specific examples of your work.

- Showcase your knowledge of quality control procedures and inspection techniques.

3. Prepare for Common Interview Questions

Anticipate and prepare for common interview questions about your experience, qualifications, and motivation for the role.

- Practice answering questions related to your inspection methods and quality control measures.

- Prepare examples of how you have handled challenging inspection situations.

4. Be Professional and Enthusiastic

Dress professionally, arrive on time, and maintain a positive and enthusiastic demeanor throughout the interview.

- Demonstrate your passion for quality control and your commitment to delivering exceptional products.

- Ask thoughtful questions to show your interest and engage the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Finished Stock Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!