Feeling lost in a sea of interview questions? Landed that dream interview for Fishing Floats Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fishing Floats Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

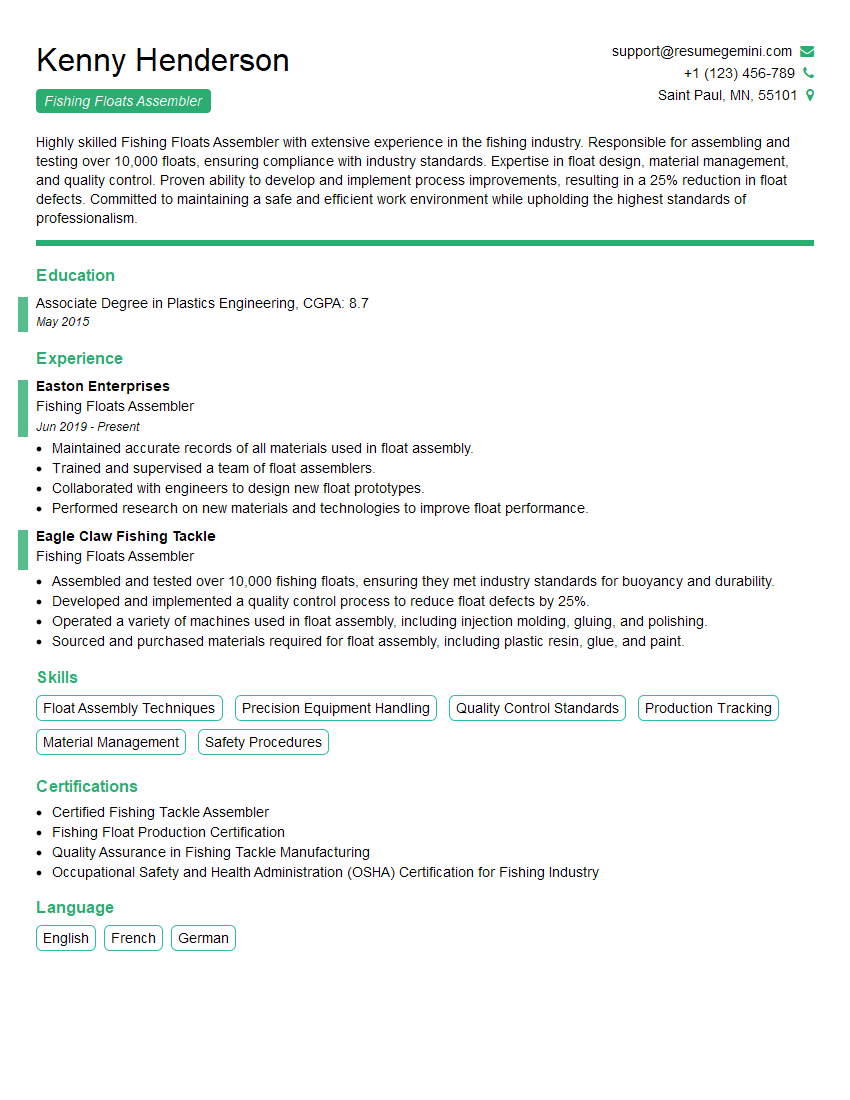

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fishing Floats Assembler

1. Describe the key steps involved in assembling a fishing float.

- Preparing the materials, including the float body, antenna, and weight

- Attaching the antenna to the float body using adhesive or a crimping tool

- Inserting the weight into the float body, ensuring proper balance and buoyancy

- Testing the float in water to verify its performance and make any necessary adjustments

- Applying a protective coating or paint to enhance durability and aesthetics

2. Explain the different types of fishing floats and their specific applications.

Bobber Floats

- Used for keeping bait suspended at a desired depth

- Common for general fishing, such as bobber fishing for panfish

Slip Floats

- Allow the bait to move freely along the line while providing tension

- Suitable for live bait presentations, such as drifting minnows for trout

Controller Floats

- Used in trolling applications to control the depth and speed of lures

- Typically designed with fins or wings for stability and tracking

3. What are the important factors to consider when selecting fishing floats?

- Target species and fishing technique

- Water depth and current conditions

- Size and weight of the bait

- Visibility and sensitivity desired

- Durability and price

4. How do you ensure the accuracy and consistency of your float assemblies?

- Using precise measuring tools and templates

- Maintaining a clean and organized work area

- Following established assembly procedures and specifications

- Regularly inspecting and calibrating equipment

- Seeking feedback from anglers and making improvements as necessary

5. Describe your experience in troubleshooting common issues related to fishing floats.

- Identifying float leakage and repairing with waterproof adhesives

- Adjusting float buoyancy by inserting or removing weights

- Replacing damaged antennas or weights to ensure proper performance

- Analyzing float behavior in water to diagnose and correct stability problems

- Providing guidance to anglers on float selection and usage

6. Explain the different materials used in fishing float construction and their respective properties.

Balsa Wood

- Lightweight and buoyant, providing excellent sensitivity

- Prone to waterlogging and damage if not properly sealed

Foam

- Durable and waterproof, offering versatility and longevity

- Can be less sensitive than balsa wood in some applications

Plastic

- Affordable and resistant to damage, suitable for general fishing

- May not offer the same buoyancy or sensitivity as balsa wood or foam

7. Discuss the importance of quality control in fishing float production.

- Ensuring consistent performance and meeting customer expectations

- Minimizing defects and reducing returns or complaints

- Maintaining brand reputation and credibility

- Improving production efficiency and reducing waste

- Complying with industry standards and regulations

8. How do you stay up-to-date with the latest innovations and trends in fishing float design?

- Attending industry trade shows and conferences

- Reading fishing publications and online forums

- Collaborating with anglers and float manufacturers

- Experimenting with new materials and techniques

- Seeking feedback and suggestions from customers

9. Describe your experience in working in a team environment, specifically in relation to float assembly.

- Coordinating with colleagues to ensure efficient production

- Sharing knowledge and assisting others in troubleshooting issues

- Maintaining a positive and collaborative work atmosphere

- Meeting deadlines and quality standards as a team

- Providing support and training to new or less experienced team members

10. Why are you interested in this Fishing Float Assembler position, and what skills and experiences make you a suitable candidate?

- Passion for fishing and interest in float assembly

- Demonstrated ability in assembling fishing floats with precision and accuracy

- Understanding of float design, materials, and troubleshooting techniques

- Experience in a manufacturing or assembly environment

- Dedication to quality control and meeting production targets

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fishing Floats Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fishing Floats Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fishing Floats Assembler is a vital role within the fishing industry, responsible for assembling and inspecting fishing floats that meet quality standards. These floats are used by anglers to keep their bait suspended at a desired depth in the water.

The key job responsibilities of a Fishing Floats Assembler include:

1. Assembling Fishing Floats

Assembling fishing floats requires precision and attention to detail. The assembler follows specified instructions and utilizes various tools and techniques to join different components of the float, such as the body, stem, and antenna. They ensure proper alignment, secure connections, and adherence to design specifications.

2. Inspecting Fishing Floats

Quality inspection is crucial to ensure that the assembled floats meet the required standards and perform effectively on the water. The assembler visually examines each float for any defects, imperfections, or damage. They check for proper buoyancy, balance, and durability to guarantee that the floats will function as intended.

3. Maintaining Assembly Area

The assembler maintains a clean and organized work area to facilitate efficient and safe float assembly. They ensure that tools and materials are properly stored, and they dispose of waste materials responsibly. They also participate in regular cleaning and maintenance of equipment to maintain optimal functionality.

4. Safety Compliance

Safety is paramount in any assembly role. The assembler follows established safety protocols, wears appropriate personal protective equipment, and operates machinery and tools safely. They maintain a safe work environment and report any potential hazards or concerns to supervisors.

Interview Preparation Tips

1. Research the Company and Industry

Before the interview, conduct thorough research on the company you are applying to, as well as the fishing industry as a whole. This will provide you with a strong understanding of the company’s values, products or services, and the current market trends. Knowledge of the industry will demonstrate your genuine interest and commitment to the field.

2. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. Anticipate questions related to your technical skills, experience in float assembly, and ability to work in a production environment. Consider using the STAR method to structure your responses, providing specific examples and quantifying your accomplishments whenever possible.

3. Highlight Your Technical Skills and Experience

Emphasize your proficiency in assembling and inspecting fishing floats, as well as your familiarity with different types of materials and tools used in the process. If you have any relevant certifications or training, make sure to mention them during the interview.

4. Showcase Your Quality Control Mindset

Highlight your commitment to quality and your ability to identify and rectify defects. Explain your understanding of quality control standards and provide examples of how you ensure that your work meets the required specifications.

5. Demonstrate Your Adaptability and Team Spirit

Production environments can be fast-paced and require adaptability. Emphasize your ability to work effectively both independently and as part of a team. Share examples of how you have handled changes in workload or adapted to new processes while maintaining productivity.

6. Ask Informed Questions

At the end of the interview, ask thoughtful questions to demonstrate your enthusiasm and engagement. This could include questions about the company’s growth plans, the role of the assembly team within the production process, or any opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fishing Floats Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!