Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Fixing Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Fixing Machine Operator so you can tailor your answers to impress potential employers.

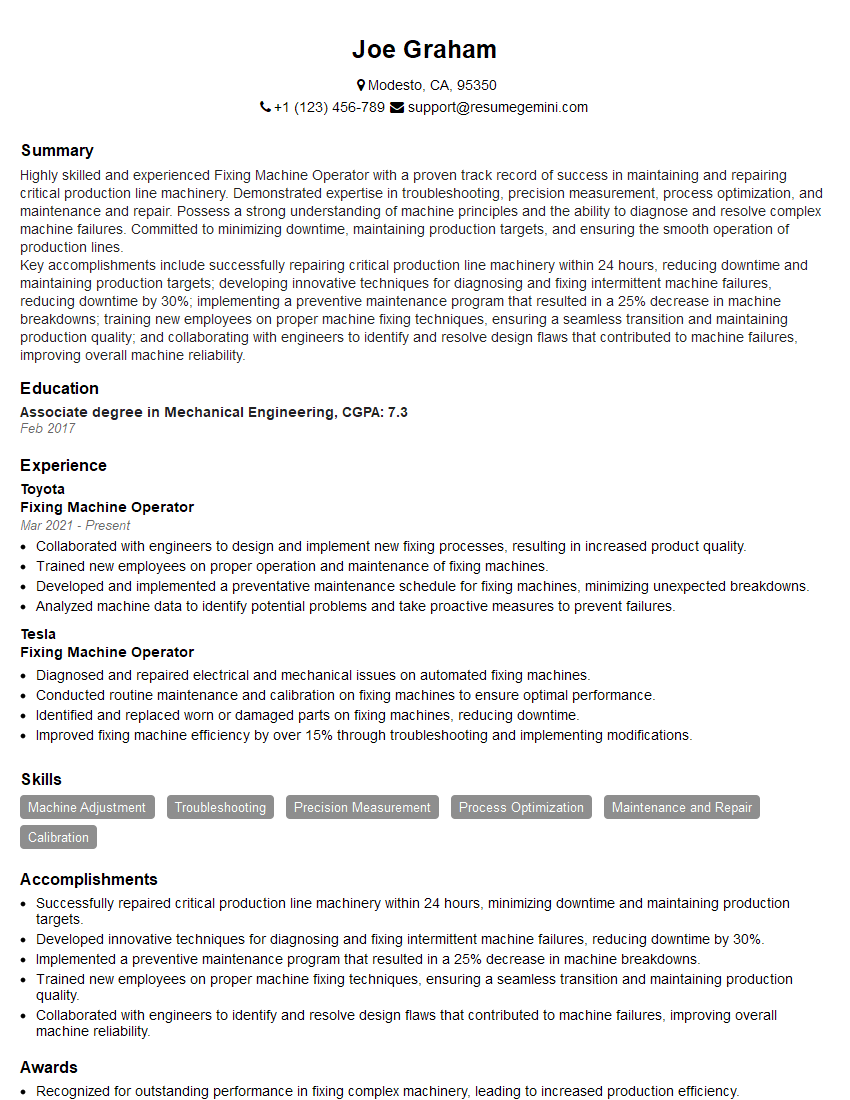

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fixing Machine Operator

1. What are the key responsibilities of a Fixing Machine Operator?

As a Fixing Machine Operator, my key responsibilities include:

- Operating and maintaining fixing machines

- Setting up and adjusting machines to meet production requirements

- Monitoring machine performance and making necessary adjustments

- Inspecting and testing fixed products to ensure quality standards

- Troubleshooting and resolving any machine or product issues

2. Can you explain the different types of fixing machines and their applications?

There are several types of fixing machines used in various industries, each with its specific applications:

Heat-set machines:

- Used for fixing dyes and finishes on textiles and fabrics

- Involve heating the fabric to a precise temperature to set the dyes

Steamers:

- Used to fix dyes on fabrics and garments

- Involve exposing the fabric to high-pressure steam to set the dyes

Dryers:

- Used to remove moisture from products after fixing

- Employ heat or air circulation to dry the products

3. What are the most common problems you have encountered as a Fixing Machine Operator, and how did you resolve them?

Some of the common problems I have faced and resolved as a Fixing Machine Operator include:

- Machine breakdowns: Identified the cause of the breakdown, repaired or replaced faulty components, and ensured the machine was operating correctly.

- Product quality issues: Analyzed the defects, adjusted machine settings, and implemented corrective actions to improve product quality.

- Production delays: Troubleshooted the cause of delays, optimized machine performance, and implemented process improvements to increase efficiency.

4. How do you ensure the quality of fixed products?

To ensure the quality of fixed products, I follow a rigorous process that includes:

- Visual inspection: Inspecting products for any visible defects or imperfections.

- Functional testing: Testing products to ensure they meet performance specifications.

- Adherence to quality standards: Following established quality standards and procedures to maintain consistency and meet customer requirements.

5. What are the safety precautions that you take when operating fixing machines?

Safety is paramount when operating fixing machines, and I adhere to the following precautions:

- Proper clothing and PPE: Wearing appropriate clothing, gloves, and eye protection to prevent injuries.

- Machine guarding: Ensuring that all machine guards are in place and operational.

- Hazard identification: Recognizing potential hazards and taking steps to minimize risks.

- Emergency procedures: Familiarizing myself with emergency procedures and knowing how to respond in case of an incident.

6. What is your experience with preventive maintenance of fixing machines?

Preventive maintenance is crucial to ensure optimal machine performance and prevent breakdowns. My experience includes:

- Regular inspections: Conducting regular inspections to identify potential issues and address them proactively.

- Equipment lubrication: Lubricating moving parts regularly to minimize wear and tear.

- Calibration and adjustments: Calibrating and adjusting machines as needed to maintain accuracy and efficiency.

- Record-keeping: Maintaining detailed records of all maintenance activities for future reference.

7. Can you describe your experience with troubleshooting fixing machine issues?

Troubleshooting is an essential skill in my role. My approach involves:

- Identifying the problem: Analyzing machine behavior, error codes, and other indicators to determine the root cause of the issue.

- Isolating the issue: Narrowing down the problem to a specific component or process.

- Repairing or replacing: Fixing or replacing faulty components as necessary.

- Testing and verification: Thoroughly testing the machine after repairs to ensure it is functioning correctly.

8. What are the different types of fabrics and materials that you have worked with as a Fixing Machine Operator?

I have experience working with a wide range of fabrics and materials, including:

- Textiles: Cotton, polyester, nylon, silk, and blends

- Garments: Shirts, pants, dresses, and outerwear

- Non-woven materials: Felt, fleece, and synthetic fibers

- Leather and vinyl: Upholstery, footwear, and accessories

9. How do you stay up-to-date with the latest developments in fixing machine technology?

To stay abreast of industry advancements, I engage in continuous learning activities:

- Attending industry events: Participating in conferences, workshops, and trade shows to learn about new technologies and best practices.

- Reading industry publications: Subscribing to technical journals and online resources to stay informed about the latest developments.

- Networking with peers: Connecting with other Fixing Machine Operators and professionals to exchange knowledge and experiences.

10. What is your approach to working in a team environment?

In a team environment, I am a collaborative and supportive member who values teamwork. My approach includes:

- Effective communication: Clearly communicating my ideas, seeking input from others, and actively listening to different perspectives.

- Problem-solving: Working together to identify and resolve issues, brainstorming solutions, and sharing knowledge.

- Respect and support: Treating colleagues with respect, offering assistance when needed, and recognizing their contributions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fixing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fixing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fixing Machine Operators are responsible for the smooth functioning of equipment and machinery in a production or manufacturing environment. Their primary focus is to ensure that all equipment operates at optimal levels, minimizing downtime and maximizing productivity.

1. Equipment Maintenance and Troubleshooting

Fixing Machine Operators conduct routine maintenance and inspections on machines to identify potential issues and prevent breakdowns. They also diagnose and troubleshoot any mechanical failures or malfunctions, using their technical knowledge and experience to find solutions.

- Conducting regular inspections and preventive maintenance on equipment

- Diagnosing and repairing mechanical failures or malfunctions

- Replacing defective parts and components

- Performing adjustments and calibrations to ensure optimal performance

2. Machine Programming and Setup

Fixing Machine Operators are responsible for programming and setting up machines according to production requirements. They use their knowledge of machine operations and programming languages to input the necessary commands and parameters to ensure efficient and accurate operation.

- Programming and setting up machines for specific production tasks

- Creating and modifying machine programs to optimize performance

- Monitoring and adjusting machine settings during operation

- Ensuring that machines meet safety and quality standards

3. Production Support and Quality Control

Fixing Machine Operators play a critical role in supporting production processes and maintaining product quality. They monitor machine performance, identify and resolve any issues that arise, and ensure that products meet specifications.

- Monitoring machine performance and productivity

- Identifying and resolving production issues and bottlenecks

- Conducting quality control checks on products

- Making adjustments to machines and processes to improve quality

4. Safety and Compliance

Fixing Machine Operators are responsible for maintaining a safe and compliant work environment. They adhere to safety protocols, follow proper procedures, and ensure that machines operate in a manner that minimizes risks to employees and the surrounding environment.

- Following all safety protocols and procedures

- Identifying and mitigating potential hazards

- Performing lockout/tagout procedures

- Ensuring that machines meet environmental and regulatory standards

Interview Tips

Preparing for an interview for a Fixing Machine Operator position requires a combination of technical knowledge, preparation, and effective communication skills. Here are a few tips to help you ace the interview:

1. Research the Company and the Role

Take the time to research the company you’re applying to and the specific role you’re interested in. Familiarize yourself with their products, services, industry, and culture. Understanding the company’s values and goals will help you tailor your answers and demonstrate your alignment with their mission.

2. Highlight Your Technical Skills

In your resume and during the interview, emphasize your technical skills and experience in equipment maintenance and repair. Describe your proficiency in diagnosing and troubleshooting mechanical issues, programming machines, and performing preventive maintenance tasks. Quantify your accomplishments and provide specific examples of projects or situations where you successfully resolved equipment problems.

3. Demonstrate Problem-Solving Abilities

Fixing Machine Operators are often faced with unexpected challenges and problems on the job. During the interview, highlight your ability to think critically, identify root causes, and develop effective solutions. Share examples of how you’ve successfully diagnosed and repaired complex equipment issues and how you ensured that the equipment met production requirements after repair.

4. Emphasize Safety and Compliance

Safety is paramount in manufacturing environments. In your interview, emphasize your commitment to safety and compliance. Discuss your understanding of safety regulations and protocols, and highlight your experience in following proper lockout/tagout procedures and ensuring that machines meet environmental and regulatory standards.

5. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. Common questions may include:

- Tell me about your experience in repairing and maintaining industrial machinery.

- Describe a time when you successfully diagnosed and resolved a complex equipment issue.

- How do you ensure that machines operate safely and efficiently?

- What are your strengths as a Fixing Machine Operator?

- Why are you interested in this role and our company?

6. Be Confident and Enthusiastic

Confidence is key in any interview. Maintain a positive and enthusiastic attitude throughout the interview. Be clear and articulate in your responses, and don’t be afraid to ask questions to clarify the interviewer’s expectations. Your enthusiasm for the role and the industry will be evident to the interviewer and will make a lasting impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Fixing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!