Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flakeboard Line Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flakeboard Line Tender so you can tailor your answers to impress potential employers.

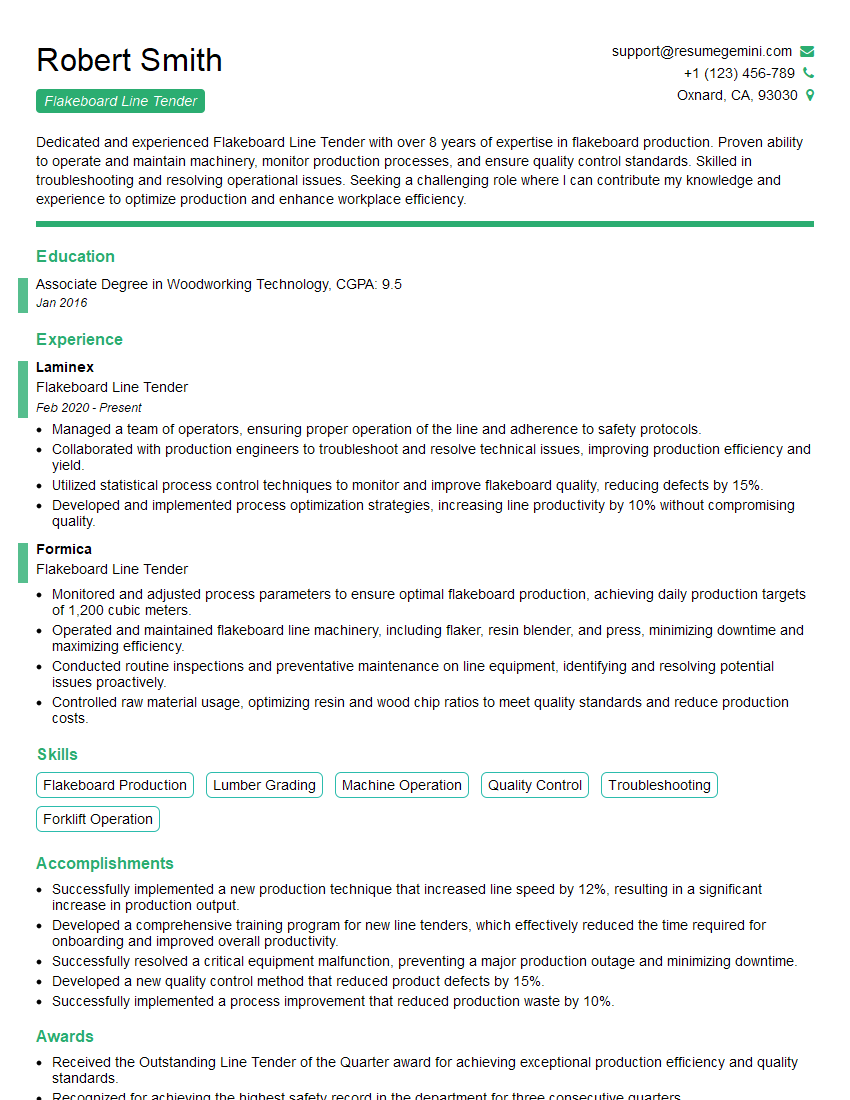

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flakeboard Line Tender

1. Describe the process of setting up a flakeboard line?

To set up a flakeboard line, I first need to check that all the necessary equipment and materials are available and in good working order. Then, I need to set the machine parameters, including the speed, temperature, and pressure. Once the parameters are set, I need to calibrate the machine and run some test boards to ensure that the quality of the flakeboard is acceptable. Finally, I need to start the production process and monitor the line to ensure that it is running smoothly.

2. What are the key factors that affect the quality of flakeboard?

The key factors that affect the quality of flakeboard include:

Raw materials:

- The type of wood used

- The quality of the wood chips

Process parameters:

- The temperature of the press

- The pressure of the press

- The speed of the press

Equipment:

- The condition of the press

- The condition of the other equipment used in the production process

3. How do you troubleshoot problems with a flakeboard line?

To troubleshoot problems with a flakeboard line, I first need to identify the source of the problem. Once I have identified the source of the problem, I need to take steps to correct it. Some common problems with flakeboard lines include:

- The flakeboard is not bonding properly

- The flakeboard is too thick or too thin

- The flakeboard is not smooth

4. What are the safety precautions that you need to take when working on a flakeboard line?

The safety precautions that I need to take when working on a flakeboard line include:

- Wearing appropriate safety gear, such as gloves, safety glasses, and a hard hat

- Being aware of the moving parts of the machine

- Keeping the work area clean and free of debris

- Following all safety procedures

5. What is your experience with operating flakeboard lines?

I have been operating flakeboard lines for the past 5 years. During that time, I have successfully set up and operated a variety of flakeboard lines, including lines that produce different types of flakeboard, such as particleboard, medium-density fiberboard, and high-density fiberboard. I am also familiar with the different types of equipment used in the production of flakeboard, and I am able to troubleshoot and repair problems with flakeboard lines.

6. What are your strengths and weaknesses as a flakeboard line tender?

Strengths:

- I am a highly skilled and experienced flakeboard line tender.

- I have a strong understanding of the flakeboard production process.

- I am able to troubleshoot and repair problems with flakeboard lines.

- I am a team player and I am able to work effectively with others.

Weaknesses:

- I do not have any formal training in flakeboard production.

- I am not familiar with all of the different types of flakeboard lines.

7. What are your career goals?

My career goals are to become a supervisor in the flakeboard industry. I would like to continue to develop my skills and knowledge of the flakeboard production process. I am also interested in learning more about the business side of the flakeboard industry.

8. Why do you want to work for our company?

I want to work for your company because you are a leading manufacturer of flakeboard products. I am impressed by your commitment to quality and innovation, and I believe that my skills and experience would be a valuable asset to your team.

9. What is your availability?

I am available to work immediately.

10. Do you have any questions for me?

Yes, I have a few questions:

- What is the starting salary for this position?

- What are the benefits offered by the company?

- What is the company’s culture like?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flakeboard Line Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flakeboard Line Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flakeboard Line Tenders are responsible for operating and maintaining the equipment used to produce flakeboard, a type of engineered wood product made from wood flakes bonded together with glue. They ensure that the equipment is running properly and that the flakeboard is produced to quality standards.

1. Equipment Operation

Flakeboard Line Tenders operate a variety of equipment, including:

- Flakeboard presses

- Sanders

- Conveyors

- Blenders

2. Quality Control

Flakeboard Line Tenders are responsible for ensuring that the flakeboard produced meets quality standards. They inspect the flakeboard for defects and make sure that it is the correct thickness, width, and length.

3. Maintenance

Flakeboard Line Tenders perform routine maintenance on the equipment they operate. They also troubleshoot problems and make repairs as needed.

4. Safety

Flakeboard Line Tenders are responsible for following all safety procedures. They wear personal protective equipment and operate equipment safely.

Interview Tips

There are a few things you can do to prepare for your Flakeboard Line Tender interview:

1. Research the Company

Before you go to your interview, take some time to research the company you are applying to. This will give you a better understanding of their culture and values, and you can tailor your answers to their specific needs.

2. Practice your Answers

You can practice answering common interview questions by yourself or with a friend. This will help you feel more confident and prepared during the interview.

3. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you are not.

4. Be Enthusiastic

Flakeboard Line Tenders are often responsible for working long hours in a challenging environment. The interviewer wants to see that you are enthusiastic about the job and that you are willing to work hard.

Next Step:

Now that you’re armed with the knowledge of Flakeboard Line Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Flakeboard Line Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini