Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flaker Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flaker Operator so you can tailor your answers to impress potential employers.

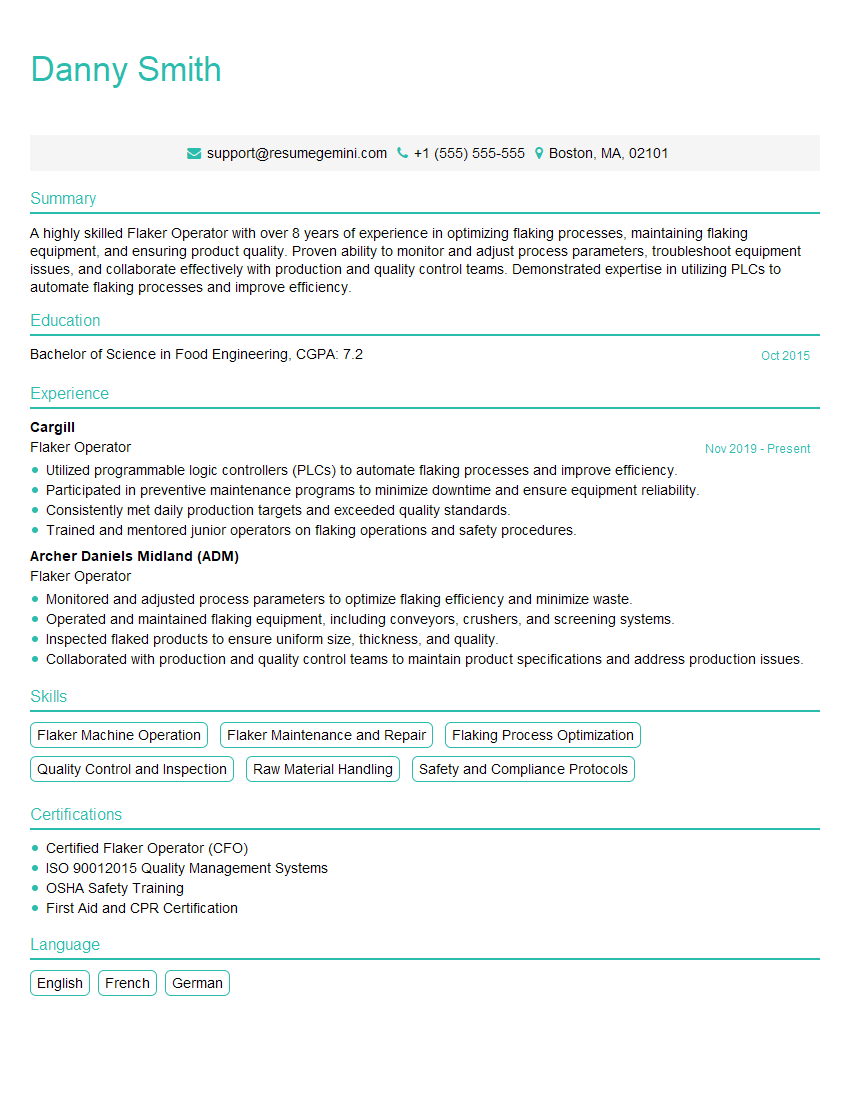

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flaker Operator

1. Describe the process of flake ice production?

- Describe the flaker and evaporator, and how they interact during flake ice production.

- Explain the methods of distributing fresh water during flake ice production.

2. How do you ensure the quality of flake ice produced?

Quality Control Measures

- Monitoring temperature and thickness of flake ice.

- Conducting physical inspections for clarity and purity.

Sanitation and Hygiene Practices

- Maintaining a clean and sanitary work environment.

- Following proper handling and storage protocols to prevent contamination.

3. How do you troubleshoot common problems that can occur during flake ice production?

- Identify potential issues such as clogged nozzles, compressor malfunctions, and power outages.

- Describe the steps taken to diagnose and resolve these problems efficiently.

- Emphasize the importance of preventive maintenance to minimize breakdowns.

4. How do you handle the storage and distribution of flake ice?

- Describe the methods used for storing flake ice, such as insulated bins and silos.

- Explain the equipment and techniques used for distributing flake ice to users, such as conveyors and pneumatic systems.

5. What safety precautions should be observed when working with flake ice production equipment?

- Discuss the potential hazards associated with flake ice production, such as slips and falls, exposure to cold temperatures, and machinery accidents.

- Describe the personal protective equipment (PPE) required and the safe operating procedures that must be followed.

6. How do you prioritize tasks and manage your time effectively in a fast-paced environment?

- Explain your approach to prioritizing tasks based on urgency and importance.

- Describe techniques used to optimize efficiency and minimize downtime.

- Discuss the importance of teamwork and collaboration in maintaining productivity.

7. How do you stay updated on the latest advancements and best practices in flake ice production?

- Describe methods for staying abreast of new technologies and industry trends.

- Discuss the importance of professional development and continuing education.

8. Can you explain the role of automation in modern flake ice production facilities?

- Describe the benefits of automation, such as increased efficiency, reduced labor costs, and improved product quality.

- Discuss the types of automation systems used in flake ice production, such as programmable logic controllers (PLCs) and distributed control systems (DCSs).

9. How do you handle emergency situations, such as power outages or equipment failures, that may arise during flake ice production?

- Describe the emergency response plan and procedures in place.

- Explain the steps taken to minimize the impact on production and ensure the safety of personnel.

10. What is your approach to continuous improvement in the flake ice production process?

- Describe methods for identifying areas for improvement.

- Discuss techniques for implementing and evaluating improvement initiatives.

- Emphasize the importance of data analysis and performance monitoring.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flaker Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flaker Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flaker Operators play a crucial role in maintaining the smooth operations of flake-producing facilities. Their primary responsibilities include:

1. Flaker Operation

Operate and control flaking equipment, ensuring its efficient performance.

- Monitor and adjust machine settings to optimize flake quality and production.

- Troubleshoot and resolve equipment malfunctions to minimize downtime.

2. Quality Control

Monitor flaker performance and maintain flake quality according to established standards.

- Inspect flakes visually or using automated systems to ensure they meet specifications.

- Analyze flake samples to verify their thickness, size, and other quality parameters.

3. Maintenance

Conduct routine maintenance and cleaning of flaking equipment to ensure its longevity.

- Lubricate moving parts, replace worn components, and perform preventive maintenance.

- Maintain a clean and safe work environment around flaking machines.

4. Safety Compliance

Adhere to established safety protocols to minimize risks and accidents.

- Wear protective gear, follow lockout/tagout procedures, and operate equipment safely.

- Report any hazardous conditions or unsafe practices to supervisors immediately.

Interview Tips

To ace your Flaker Operator interview, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific responsibilities of the Flaker Operator role.

- Visit the company website, read industry publications, and connect with employees on LinkedIn.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as flaker operation, quality control, and maintenance experience.

- Quantify your accomplishments and provide specific examples of how you contributed to process optimization and quality improvement.

3. Demonstrate Safety Consciousness

Flaker Operators have a crucial role in maintaining a safe work environment.

- Highlight your understanding of safety protocols and your commitment to adhering to them.

- Share examples of how you identified and addressed potential hazards in previous roles.

4. Prepare for Technical Questions

Be prepared to answer questions about flaking equipment, quality control techniques, and maintenance procedures.

- Review technical terms and concepts related to flaking operations.

- Practice troubleshooting scenarios and explaining your approach to solving common problems.

5. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately and arrive for your interview on time.

- Wear business casual attire or follow the company’s dress code.

Next Step:

Now that you’re armed with the knowledge of Flaker Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Flaker Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini