Are you gearing up for a career in Flaking Roll Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Flaking Roll Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

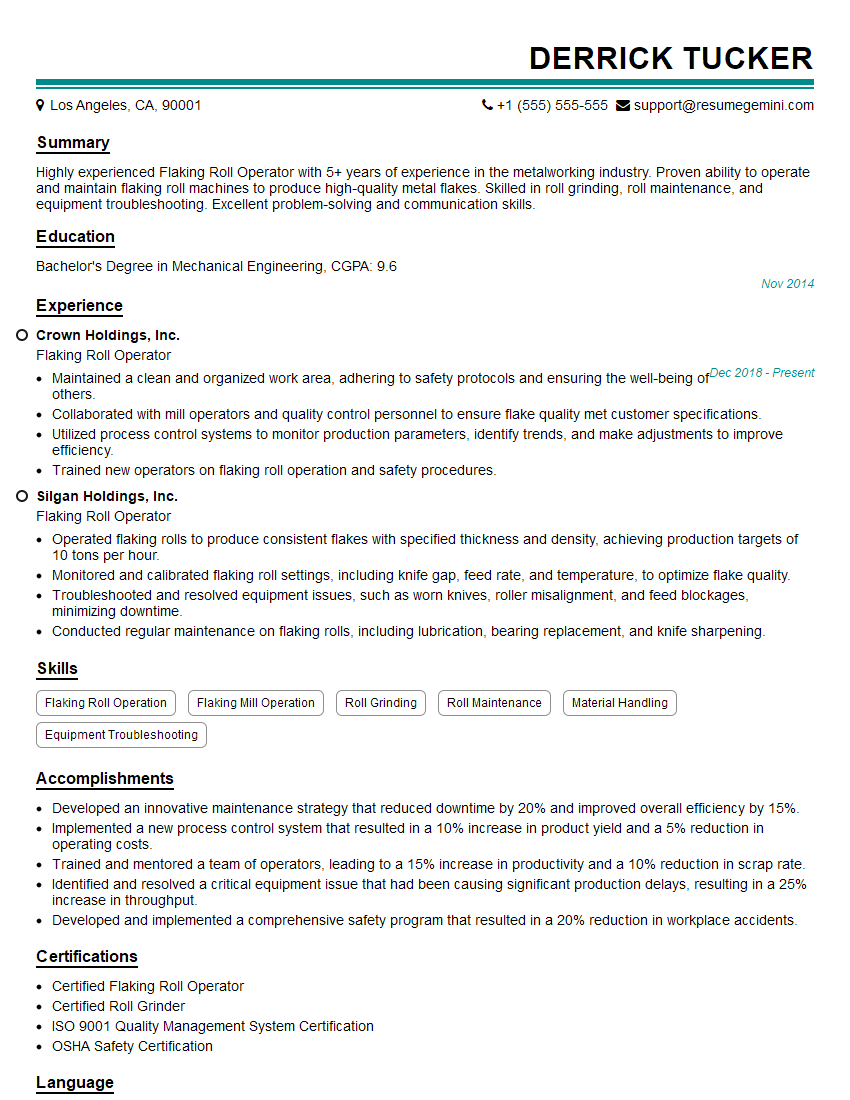

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flaking Roll Operator

1. What is the purpose of the flaking rolls in the production process?

- To reduce the thickness of the dough by pressing it between two rotating rolls

- To create a uniform thickness throughout the dough, ensuring consistent baking

- To improve the texture and structure of the dough, making it more tender and flaky

2. Describe the process of setting up the flaking rolls for a specific product.

Adjusting the Roll Gap:

- Determine the desired thickness of the dough and adjust the gap between the rolls accordingly

- Use shims or spacers to set the correct gap and ensure uniform thickness

Lubricating the Rolls:

- Apply a food-grade lubricant to the rolls to prevent dough from sticking and reduce friction

- Ensure that the lubricant is compatible with the dough and does not affect its flavor or quality

3. How do you troubleshoot common problems that arise during flaking operations?

- Dough sticking to rolls: Adjust roll gap, lubricate rolls, check dough consistency

- Uneven dough thickness: Recalibrate roll gap, inspect rolls for wear or damage

- Over-flaking: Reduce roll speed, increase roll gap, adjust dough thickness

4. What are the safety precautions that must be followed when operating flaking rolls?

- Wear appropriate safety gear (gloves, hairnet, safety glasses)

- Keep hands away from moving parts and rotating rolls

- Report any malfunctions or hazards to a supervisor immediately

- Follow proper lockout/tagout procedures when performing maintenance or repairs

5. How do you maintain and calibrate flaking rolls to ensure optimal performance?

- Regularly clean and lubricate rolls to prevent wear and tear

- Inspect rolls for damage or wear and replace as needed

- Calibrate roll gap regularly using shims or spacers to maintain consistent thickness

- Monitor roll temperature and adjust lubrication as necessary to prevent overheating

6. What are the different types of doughs that can be flaked, and how do their properties affect the flaking process?

- Laminated doughs: Require precise roll gap control and careful lubrication to achieve desired flakiness

- Yeast-based doughs: Need longer flaking times and may require additional lubrication to prevent sticking

- Cookie doughs: Have a higher butter content, making them more challenging to flake evenly

7. How do you determine the correct roll speed and pressure for a given dough?

- Consider the dough’s consistency, thickness, and desired flakiness level

- Start with low speed and pressure and gradually increase as needed

- Monitor the dough’s texture and thickness during flaking to adjust speed and pressure accordingly

8. What is the role of temperature control in flaking operations?

- Dough temperature affects its consistency and flow through the rolls

- Maintaining optimal dough temperature helps prevent sticking and ensures consistent flaking

- Rolls should be at the correct temperature to prevent dough from overheating or cooling too quickly

9. How do you handle quality control issues related to flaking?

- Monitor dough thickness and flakiness during production

- Identify and correct any deviations from specifications

- Document quality control measures and maintain records for traceability

- Communicate with production and maintenance teams to ensure continuous improvement

10. What are the latest innovations and best practices in flaking roll technology?

- Automated roll gap adjustment systems for greater precision and consistency

- Improved lubrication systems to reduce downtime and maintenance costs

- Temperature-controlled rolls for optimal dough handling

- Data analytics and machine learning to optimize flaking processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flaking Roll Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flaking Roll Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flaking Roll Operators play a crucial role in the production of various products in a variety of industries. Their primary responsibilities include:

1. Machine Operation

Flaking Roll Operators are responsible for the safe and efficient operation of flaking rolls, ensuring that they produce uniform and high-quality flakes.

- Monitor and adjust machine settings, including speed, pressure, and temperature, to optimize production

- Inspect raw materials and ensure they meet specifications before processing

2. Production Monitoring

Flaking Roll Operators closely monitor the production process to ensure that flakes meet the desired specifications and quality standards.

- Monitor flow rates, pressures, and other process parameters to ensure consistent flake quality

- Inspect and test flakes to ensure they meet specifications for size, thickness, and other attributes

3. Maintenance and Troubleshooting

Flaking Roll Operators are responsible for maintaining and troubleshooting the flaking rolls and associated equipment to minimize downtime and ensure smooth operation.

- Perform routine maintenance tasks, such as lubrication, cleaning, and minor repairs

- Troubleshoot and resolve equipment malfunctions, replacing worn or damaged parts as necessary

4. Quality Control

Flaking Roll Operators are responsible for ensuring the quality of the flaked products, ensuring they meet customer specifications and industry standards.

- Inspect and test flakes for quality, checking for defects, contamination, and adherence to specifications

- Maintain records of production and quality control activities to ensure traceability and compliance

Interview Tips

To ace an interview for a Flaking Roll Operator position, candidates should:

1. Research the Company and Industry

Demonstrate your understanding of the company’s operations, industry trends, and the specific role you are applying for by researching these aspects thoroughly before the interview.

- Visit the company website and review their products, services, and industry presence.

- Read industry publications and news to stay informed about the latest developments and best practices in flaking operations.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are directly relevant to the job requirements. Quantify your accomplishments whenever possible, using specific examples to demonstrate your capabilities.

- Discuss your experience in operating and maintaining flaking rolls, including any specific types or models you have worked with.

- Provide examples of how you have successfully monitored and controlled production processes to ensure product quality.

3. Prepare for Common Interview Questions

Practice answering common interview questions that are likely to be asked in a Flaking Roll Operator interview. By preparing thoughtful responses, you can present yourself confidently and effectively.

- Tell me about your experience in operating flaking rolls.

- Describe a time when you identified and resolved a problem with a flaking roll.

- How do you ensure the quality of flaked products?

4. Dress Professionally and Arrive Punctually

First impressions matter, so dress professionally and arrive for your interview on time. This demonstrates respect for the interviewer’s time and shows that you are serious about the opportunity.

Next Step:

Now that you’re armed with the knowledge of Flaking Roll Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Flaking Roll Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini