Feeling lost in a sea of interview questions? Landed that dream interview for Flame Hardening Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Flame Hardening Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

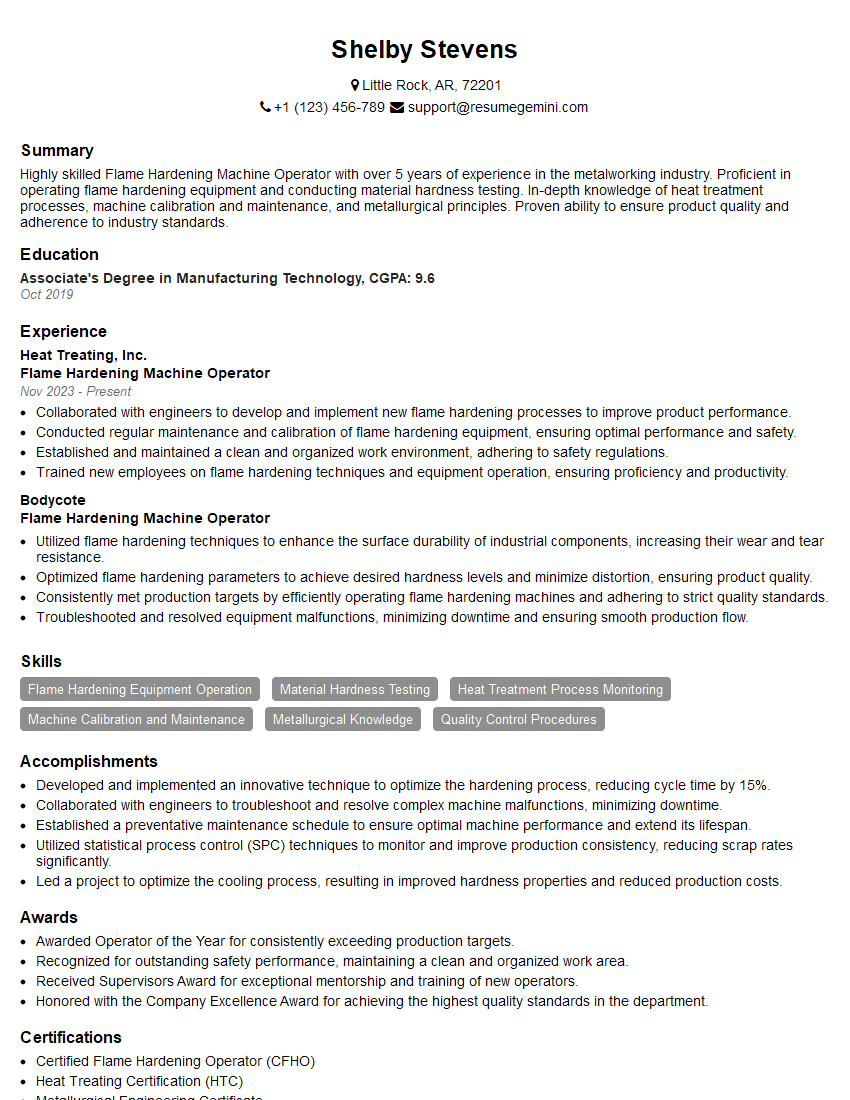

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flame Hardening Machine Operator

1. What is the purpose of flame hardening?

Flame hardening is a surface hardening process that increases the wear resistance and durability of metal components. It involves heating the surface of the metal to a high temperature using an oxy-fuel torch, then rapidly cooling it with a water or air jet. This creates a thin, hard layer on the surface while the core remains soft and tough.

2. What are the different factors that affect the depth of hardening in flame hardening?

Factors affecting depth of hardening:

- Temperature of the flame

- Speed of travel of the torch

- Distance between the torch and the workpiece

- Type and thickness of the workpiece

3. What are the advantages and disadvantages of flame hardening compared to other surface hardening processes?

Advantages:

- Fast and economical process

- Can be applied to a wide range of metals

- Minimal distortion or warping

Disadvantages:

- Limited depth of hardening

- Can cause surface cracking if not properly controlled

4. How do you ensure the quality of flame hardened components?

Quality control measures for flame hardening include:

- Visual inspection for surface defects

- Hardness testing to verify the desired hardness level

- Microstructural analysis to assess the microstructure of the hardened layer

5. What are the safety precautions that must be taken when operating a flame hardening machine?

Safety precautions for flame hardening include:

- Wearing appropriate personal protective equipment (PPE), including flame-resistant clothing, gloves, and eye protection

- Ensuring adequate ventilation to prevent the accumulation of flammable gases

- Properly grounding the workpiece and equipment to prevent electrical hazards

6. Describe the different types of flame hardening equipment.

Types of flame hardening equipment include:

- Manual torches

- Semi-automatic machines

- Fully automated systems

7. What are the different types of fuels used in flame hardening?

Common fuels used in flame hardening include:

- Acetylene

- Propane

- Natural gas

8. What are the different types of cooling media used in flame hardening?

Cooling media used in flame hardening include:

- Water

- Air

- Oil

9. What are the different applications of flame hardening?

Applications of flame hardening include:

- Gears

- Shafts

- Bearings

- Cutting tools

10. What are the career progression opportunities for a Flame Hardening Machine Operator?

Career progression opportunities for a Flame Hardening Machine Operator include:

- Senior Machine Operator

- Supervisor

- Manager

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flame Hardening Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flame Hardening Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Flame Hardening Machine Operator is entrusted with the responsibility of operating flame hardening machines and handling the entire flame hardening process. The operator ensures that the metal components undergo the optimal hardening process. The primary duties of a Flame Hardening Machine Operator include:

1. Machine Operation

The operator sets up and operates flame hardening machines according to the established procedures and work orders. They adjust machine settings, such as flame temperature, speed, and gas flow, to achieve the desired results.

2. Component Handling

The operator carefully handles metal components during the flame hardening process. They position and move components to ensure they receive uniform hardening. The operator also inspects components for defects before and after hardening.

3. Process Monitoring

The operator closely monitors the flame hardening process to ensure quality and safety. They observe the components during hardening and adjust machine settings as needed to maintain the desired hardening parameters.

4. Equipment Maintenance

The operator conducts routine maintenance and cleaning of flame hardening machines. This includes replacing worn parts, lubricating components, and ensuring the overall cleanliness of the equipment.

Interview Preparation Tips

Preparing for a Flame Hardening Machine Operator interview requires a thorough understanding of the role and the industry. Follow these tips to enhance your chances of success:

1. Research the Company and Position

Before the interview, research the company and the specific position you are applying for. Familiarize yourself with their products, services, and industry standing. Understand the responsibilities of the role and the qualifications the company seeks.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers accordingly. Practice your responses to questions about your experience, skills, and knowledge of flame hardening. Use the STAR method to provide clear and concise examples.

3. Highlight Relevant Skills and Experience

Emphasize your technical skills in flame hardening, metalworking, and machine operation. Discuss your experience in handling and inspecting metal components. Quantify your accomplishments using specific metrics and results.

4. Demonstrate Safety Consciousness

Flame hardening involves working with high temperatures and potential hazards. Highlight your commitment to safety by discussing your adherence to safety protocols and your experience in handling hazardous materials.

5. Ask Informed Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest and engagement. Inquire about the company’s projects, the training and development opportunities, and the career growth potential.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Flame Hardening Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.