Feeling lost in a sea of interview questions? Landed that dream interview for Flame Hardening Machine Setter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Flame Hardening Machine Setter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

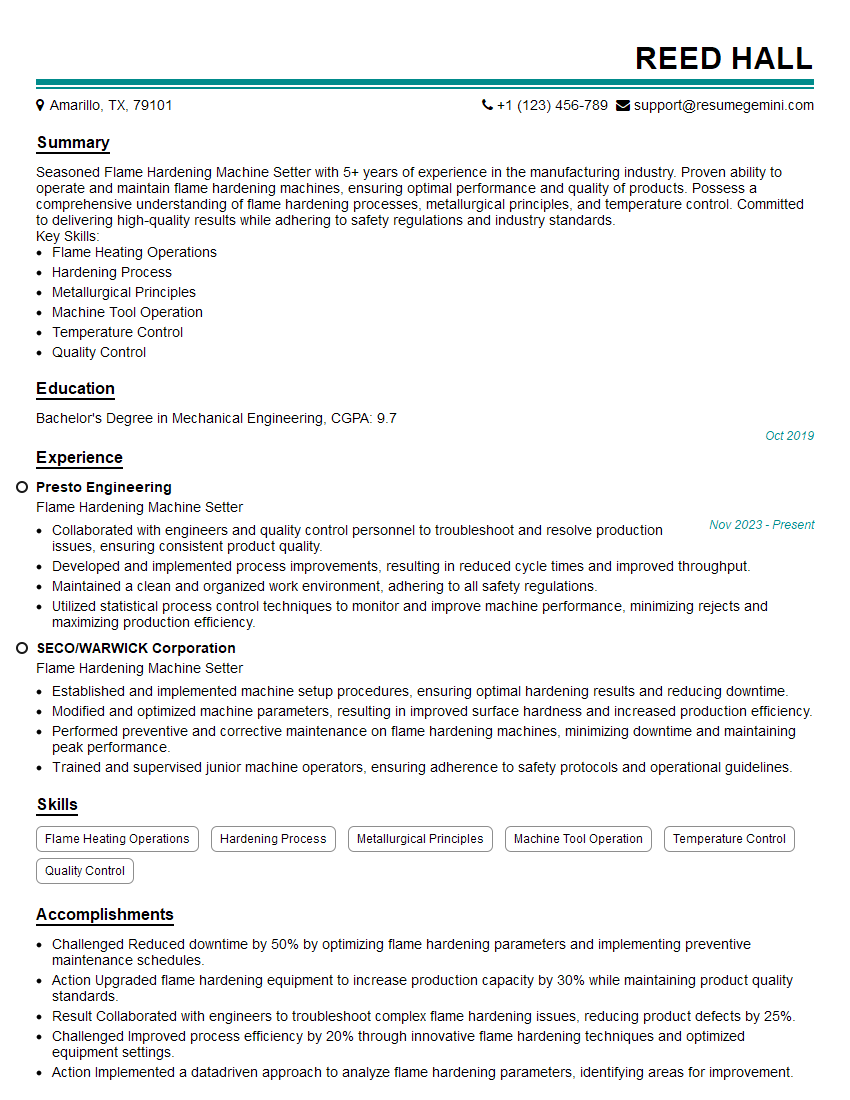

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flame Hardening Machine Setter

1. Describe the process of flame hardening?

Flame hardening is a surface hardening process that involves heating the surface of a metal workpiece to a high temperature using a flame, followed by rapid cooling. This process results in a hardened surface with improved wear resistance and hardness, while the core of the workpiece remains relatively soft and ductile.

2. What are the key parameters that need to be controlled during flame hardening?

- Temperature: The temperature of the workpiece surface must be carefully controlled to achieve the desired hardness and wear resistance.

- Heating time: The heating time must be sufficient to allow the surface to reach the desired temperature but not too long to cause excessive oxidation or distortion.

- Cooling rate: The cooling rate must be rapid enough to achieve the desired hardness and wear resistance. This can be controlled by the use of water, oil, or air as the cooling medium.

- Flame characteristics: The flame characteristics, such as flame shape, size, and composition, can affect the heating and cooling process.

3. What are the advantages of using flame hardening?

- Improved wear resistance: Flame hardening can significantly improve the wear resistance of metal surfaces.

- Increased hardness: Flame hardening can increase the hardness of metal surfaces, making them more resistant to deformation and damage.

- Enhanced fatigue strength: Flame hardening can enhance the fatigue strength of metal surfaces, making them more resistant to cracking and failure under repeated loading.

- Selective hardening: Flame hardening allows for selective hardening of specific areas of a workpiece, leaving other areas unaffected.

4. What are the different flame hardening methods?

- Progressive flame hardening: The flame is moved along the surface of the workpiece, heating and hardening it progressively.

- Stationary flame hardening: The flame is held stationary over the workpiece, heating and hardening a specific area.

- Scan flame hardening: The flame is scanned across the surface of the workpiece, creating a hardened pattern.

5. What are the safety precautions that need to be taken when operating a flame hardening machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and fire-resistant clothing.

- Ensure that the workpiece is properly secured and supported.

- Use proper ventilation to remove fumes and gases generated during the process.

- Keep the work area clear of flammable materials.

- Be aware of the potential for burns and take necessary precautions to avoid contact with hot surfaces.

6. How do you determine the appropriate flame hardening parameters for a given workpiece?

Determining the appropriate flame hardening parameters requires consideration of factors such as the material properties, the desired hardness and wear resistance, the workpiece geometry, and the available equipment. It often involves testing and experimentation to optimize the process for specific applications.

7. How do you troubleshoot common problems encountered in flame hardening?

- Excessive oxidation: This can be caused by insufficient or improper cooling, resulting in the formation of a scale on the workpiece surface.

- Distortion: This can occur due to uneven heating or cooling, causing the workpiece to bend or warp.

- Insufficient hardness: This can be caused by inadequate heating or rapid cooling, resulting in insufficient surface hardening.

- Cracking: This can occur due to excessive heating or too rapid cooling, causing the surface to become brittle and prone to cracking.

8. What are the maintenance procedures for a flame hardening machine?

- Regular cleaning and inspection of the machine to ensure proper operation and prevent malfunctions.

- Calibration and adjustment of the machine to maintain accuracy and precision.

- Replacement of worn or damaged components, such as nozzles and tips, to ensure optimal performance.

- Following manufacturer’s recommendations for maintenance and service intervals.

9. What are the quality control measures used in flame hardening?

- Hardness testing to verify the achieved hardness of the hardened surface.

- Dimensional inspection to ensure that the workpiece meets the required dimensions and tolerances.

- Visual inspection to detect any defects or abnormalities.

- Non-destructive testing methods, such as ultrasonic or magnetic particle testing, to assess the integrity of the hardened surface.

10. How do you stay updated with the latest advancements in flame hardening technology?

I regularly attend industry events, conferences, and seminars to learn about new technologies and best practices in flame hardening. Additionally, I read technical publications and online resources to stay informed about the latest developments in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flame Hardening Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flame Hardening Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flame Hardening Machine Setters are responsible for setting up and operating flame hardening machines to harden metal surfaces. They ensure that the machines are properly calibrated and maintained, and that the hardening process is carried out according to specifications.

1. Setup and Calibration

Set up and calibrate flame hardening machines according to specifications

- Install and adjust fixtures and tooling

- Ensure that the machine is level and properly grounded

- Calibrate the machine’s temperature, pressure, and flow rate settings

2. Machine Operation

Operate flame hardening machines to harden metal surfaces

- Load and unload workpieces from the machine

- Monitor the hardening process and make adjustments as needed

- Ensure that the hardened surfaces meet the desired specifications

3. Maintenance

Perform routine maintenance on flame hardening machines

- Clean and lubricate the machine

- Inspect the machine for wear and tear

- Replace worn or damaged parts

4. Troubleshooting

Troubleshoot and resolve problems with flame hardening machines

- Identify the source of the problem

- Repair or replace the faulty component

- Calibrate the machine to ensure that it is operating properly

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are some tips for nailing your Flame Hardening Machine Setter interview:

1. Research the Company

Take some time to learn about the company you’re applying to. This will help you understand their culture, values, and what they’re looking for in a Flame Hardening Machine Setter.

- Visit the company’s website

- Read their social media pages

- Talk to people who work for the company

2. Practice Your Answers

Once you have a good understanding of the company, start practicing your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Think about your strengths and weaknesses

- Prepare examples of your experience

- Practice answering questions with the STAR method

(Situation, Task, Action, Result)

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Avoid wearing jeans, t-shirts, or sneakers

- Choose clothes that are comfortable and that you can move around in easily

- Make sure your clothes are clean and free of wrinkles

4. Be Enthusiastic

Employers want to hire people who are passionate about their work. Show the interviewer that you’re excited about the opportunity to work as a Flame Hardening Machine Setter.

- Smile and make eye contact

- Speak clearly and confidently

- Be positive and enthusiastic about the company and the position

5. Ask Questions

Asking questions at the end of the interview shows the interviewer that you’re interested in the position and that you’re taking the interview seriously.

- Ask about the company’s culture

- Ask about the opportunities for advancement

- Ask about the training and development programs

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Flame Hardening Machine Setter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Flame Hardening Machine Setter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.