Are you gearing up for an interview for a Flash Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Flash Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

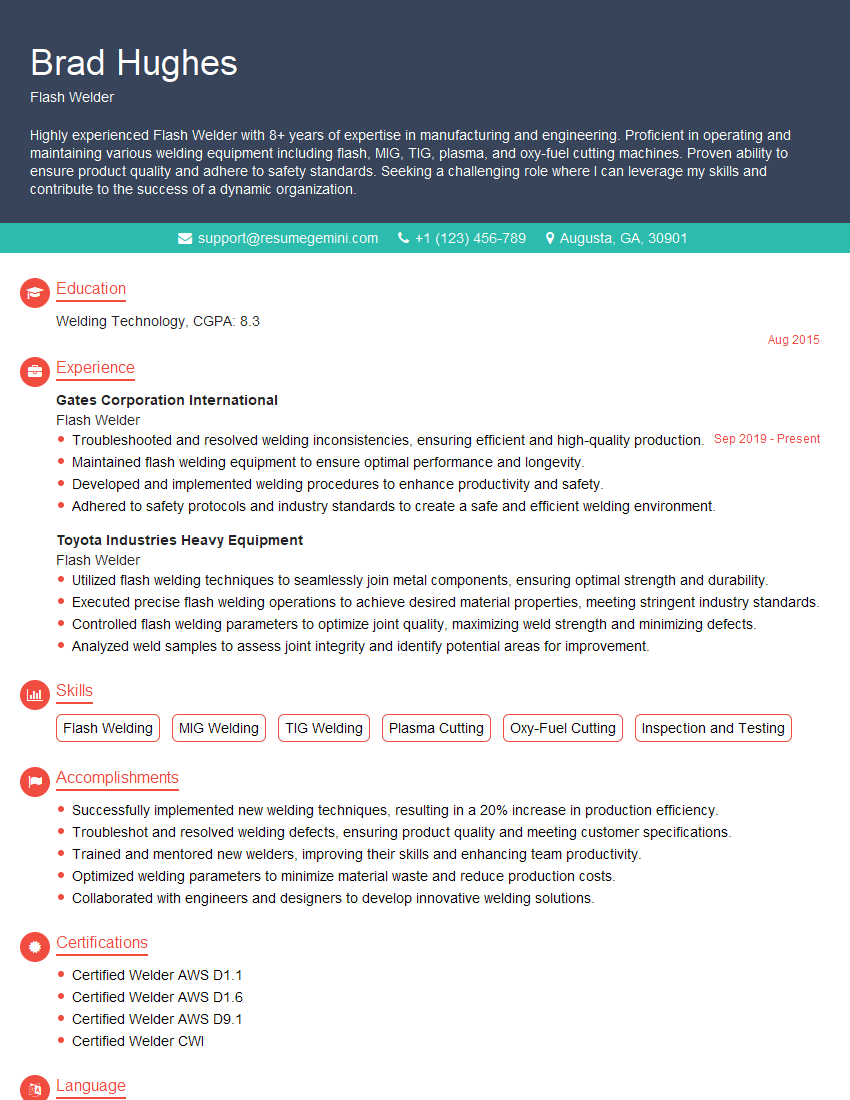

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flash Welder

1. What are the different types of flash welding machines?

- Press type flash welding machines

- Butt type flash welding machines

- Upset type flash welding machines

2. What are the advantages and disadvantages of flash welding?

Advantages

- High production rate

- Low distortion

- Good weld quality

Disadvantages

- High initial investment cost

- Limited to smaller part sizes

- Can generate fumes and sparks

3. What are the key parameters that need to be controlled during flash welding?

- Clamping force

- Flashing time

- Upset force

- Upset time

- Annealing time

4. What are the different troubleshooting techniques that can be used to resolve common flash welding defects?

- Weld cracks

- Weld porosity

- Weld spatter

- Weld undercuts

- Weld burn-throughs

5. What are the safety precautions that should be taken when working with flash welding equipment?

- Wear proper protective clothing, including gloves, eye protection, and hearing protection.

- Ensure that the welding area is well-ventilated.

- Keep flammable materials away from the welding area.

- Never operate a flash welding machine without proper training.

6. What is the difference between flash welding and resistance spot welding?

- Flash welding is a continuous welding process, while resistance spot welding is a discrete welding process.

- Flash welding produces a larger weld nugget than resistance spot welding.

- Flash welding is typically used for welding larger parts, while resistance spot welding is typically used for welding smaller parts.

7. What are the different types of materials that can be flash welded?

- Carbon steel

- Stainless steel

- Aluminum

- Copper

- Nickel

8. What are the applications of flash welding?

- Automotive industry

- Aerospace industry

- Construction industry

- Railroad industry

- Shipbuilding industry

9. What are the career opportunities for Flash Welders?

- Production Welder

- Maintenance Welder

- Welding Inspector

- Welding Supervisor

- Welding Engineer

10. What is the future of flash welding?

- Increased automation

- Improved weld quality

- New and innovative applications

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flash Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flash Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Flash Welder is a skilled professional responsible for joining metal components using flash welding techniques. Their primary duties involve operating and maintaining flash welding machines, ensuring optimal weld quality, and adhering to safety protocols.

1. Welding and Fabrication

Conduct flash welding processes to join metal components, achieving precise and durable welds.

- Set up and operate flash welding machines, adjusting welding parameters based on material properties.

- Prepare weld surfaces, clean weld joints, and ensure proper alignment.

2. Quality Control and Inspection

Monitor and evaluate weld quality using visual inspection, destructive testing, and non-destructive testing methods.

- Identify and rectify weld defects, ensuring adherence to quality standards.

- Maintain detailed records of welding parameters and inspection results.

3. Machine Maintenance and Repair

Perform routine maintenance and repairs on flash welding machines, ensuring optimal performance and longevity.

- Lubricate, clean, and calibrate machine components.

- Troubleshoot machine malfunctions and implement necessary repairs.

4. Safety Compliance

Adhere to all applicable safety regulations and industry best practices.

- Wear appropriate personal protective equipment (PPE) while welding.

- Maintain a clean and organized work area, free from hazards.

Interview Tips

Preparing thoroughly for a Flash Welder interview is crucial to showcase your skills and qualifications. Here are some tips to help you ace the interview:

1. Research the Company and Position

Demonstrate your interest and enthusiasm by researching the company and the specific Flash Welder position. This will allow you to ask informed questions and highlight your alignment with the company’s goals.

- Visit the company website to learn about their products, services, and industry standing.

- Read industry publications and articles to stay updated on the latest welding technologies and trends.

2. Emphasize Your Experience and Skills

Highlight your relevant experience and skills that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact.

- Discuss your experience in operating and maintaining flash welding machines.

- Provide examples of successful welding projects you have completed.

- Showcase your knowledge of different welding techniques, materials, and safety protocols.

3. Prepare for Technical Questions

Expect technical questions related to flash welding processes, equipment, and quality control techniques. Prepare by reviewing the basics of flash welding, troubleshooting methods, and industry standards.

- Explain the principles of flash welding and its applications.

- Describe the factors that influence weld quality and how to control them.

- Discuss the different types of weld defects and how to prevent or rectify them.

4. Practice Your Interview Responses

Practice answering common interview questions to gain confidence and deliver clear and concise responses. Seek feedback from a friend, family member, or career counselor.

- Prepare an elevator pitch highlighting your key skills and experience.

- Rehearse answers to questions about your strengths, weaknesses, and career aspirations.

- Consider potential questions related to safety, quality control, and problem-solving scenarios.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flash Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!