Are you gearing up for an interview for a Flask Fitter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Flask Fitter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

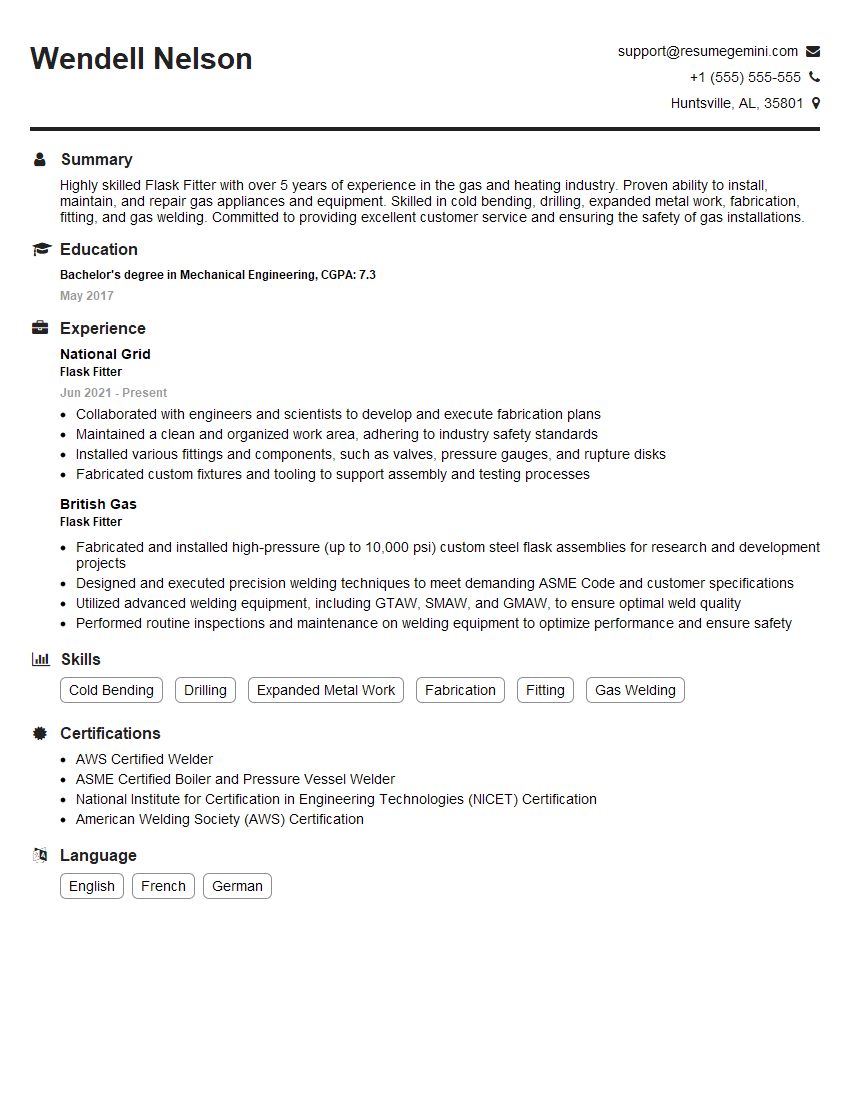

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flask Fitter

1. What are the key responsibilities of a Flask Fitter?

As a Flask Fitter, I would be responsible for installing, maintaining, and repairing various types of flasks and associated equipment. This includes tasks such as:

- Reading and interpreting technical drawings and blueprints

- Fitting and assembling flasks and other components

- Testing and inspecting flasks to ensure they meet specifications

- Troubleshooting and repairing any issues that arise

2. What types of flasks have you worked with in the past?

Glassware flasks

- Conical flasks

- Round-bottom flasks

- Volumetric flasks

Metal flasks

- Stainless steel flasks

- Aluminum flasks

- Copper flasks

3. What are the different materials used in flask construction?

The materials used in flask construction vary depending on the intended use of the flask, but common materials include:

- Glass (borosilicate glass, quartz glass)

- Metals (stainless steel, aluminum, copper)

- Plastics (polypropylene, polyethylene)

- Ceramics

4. What are the key safety considerations when working with flasks?

Working with flasks requires adherence to strict safety protocols, including:

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and lab coats

- Handling glassware carefully to avoid breakage

- Using proper chemical handling techniques when working with hazardous substances

- Being aware of potential pressure or vacuum hazards

5. How do you ensure that flasks are properly sealed and leak-proof?

Ensuring proper sealing and leak-proof flasks is crucial, and I follow these steps:

- Inspecting the flask and sealing surfaces for any damage or defects

- Using appropriate sealants or gaskets to create a tight seal

- Applying the sealant evenly and allowing it to cure properly

- Testing the seal by pressurizing or evacuating the flask

6. Describe the process of fitting a flask to a vacuum line.

Fitting a flask to a vacuum line involves the following steps:

- Selecting the appropriate adapter or connector for the flask and vacuum line

- Lubricating the adapter or connector with a suitable sealant

- Carefully inserting the flask into the adapter or connector

- Tightening the connection securely while avoiding overtightening

- Testing the seal by evacuating the flask and monitoring for any leaks

7. What cleaning procedures do you use to maintain flasks?

Proper cleaning of flasks is essential, and I follow these procedures:

- Disassembling the flask into its components

- Soaking the components in a suitable cleaning solution

- Scrubbing the components with a brush to remove any contaminants

- Rinsing the components thoroughly with water

- Drying the components completely before reassembly

8. How do you troubleshoot common problems that arise with flasks?

Troubleshooting common flask problems requires a systematic approach, including:

- Identifying the specific issue

- Examining the flask and associated equipment for any visible damage or defects

- Checking the seals and connections for leaks

- Inspecting the flask for any cracks or contamination

- Consulting technical documentation or seeking assistance from experienced colleagues

9. Describe the importance of proper documentation in flask fitting and maintenance.

Proper documentation is crucial because it:

- Provides a record of all work performed on flasks

- Facilitates communication and collaboration among team members

- Helps ensure that flasks are fitted and maintained according to specifications

- Assists in troubleshooting and problem-solving

- Complies with regulatory and safety requirements

10. How do you stay up-to-date with the latest advancements in flask fitting and maintenance techniques?

To stay current with the latest advancements, I:

- Attend industry workshops and conferences

- Read technical journals and publications

- Participate in online forums and discussion groups

- Collaborate with other professionals in the field

- Seek opportunities for professional development

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flask Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flask Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flask Fitters are responsible for installing, maintaining, and repairing flasks and other related equipment in various industries, including pharmaceutical, chemical, and food processing.

1. Installation and Assembly

Install and assemble new flasks and equipment according to specifications and drawings.

- Read and interpret blueprints and technical manuals.

- Position and align flasks and equipment correctly.

- Secure flasks and equipment using bolts, nuts, and other fasteners.

2. Maintenance and Repair

Perform routine maintenance and repairs on flasks and equipment to ensure optimal performance.

- Inspect flasks and equipment for wear, damage, or leaks.

- Clean and lubricate moving parts.

- Replace worn or damaged components.

- Troubleshoot and diagnose problems with flasks and equipment.

3. Calibration and Testing

Calibrate and test flasks and equipment to ensure accuracy and compliance with industry standards.

- Use specialized tools and equipment to calibrate flasks and equipment.

- Conduct performance tests and record results.

- Maintain calibration records and documentation.

4. Safety and Compliance

Adhere to all safety regulations and procedures when working with flasks and equipment.

- Wear appropriate personal protective equipment (PPE).

- Follow lockout/tagout procedures.

- Dispose of hazardous materials properly.

Interview Tips

Preparing thoroughly for your Flask Fitter interview can significantly increase your chances of success. Here are some valuable tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific Flask Fitter position. Understanding their industry, products or services, company culture, and the responsibilities of the role will demonstrate your interest and enthusiasm.

2. Practice Answering Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and qualifications. Practice articulating your strengths and why you’re the ideal candidate for the Flask Fitter position. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

3. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience during the interview. Focus on transferable skills, such as problem-solving, attention to detail, and teamwork. Provide specific examples of your accomplishments in previous roles that demonstrate your abilities as a Flask Fitter.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role. Prepare several questions about the company, the position, or the industry. This is an opportunity to clarify any details and demonstrate your enthusiasm.

5. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving on time for your interview. Your appearance and punctuality convey respect and attention to detail, which are essential qualities for a Flask Fitter.

6. Follow Up After the Interview

After the interview, send a thank-you note to the interviewer. Express your appreciation for their time and reiterate your interest in the position. You can also use this opportunity to clarify any additional questions or provide any missing information.

Next Step:

Now that you’re armed with the knowledge of Flask Fitter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Flask Fitter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini