Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Flat Polisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

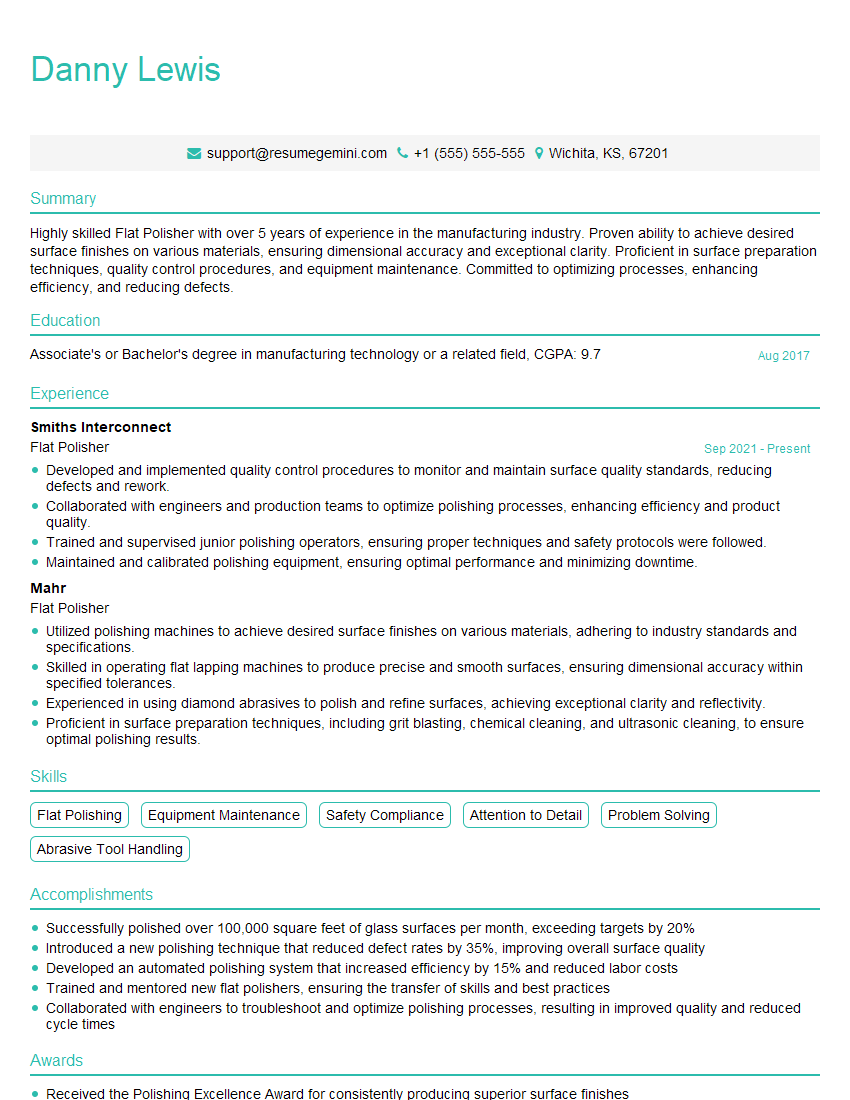

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flat Polisher

1. What are the different types of flat polishing machines and their applications?

- Rotary flat polishers: Used for large-scale production of flat surfaces, such as metal plates, glass sheets, and semiconductor wafers.

- Linear flat polishers: Used for polishing smaller, delicate surfaces, such as optical lenses and precision components.

- Wet flat polishers: Use a water-based coolant to prevent heat build-up and surface damage.

- Dry flat polishers: Use air or vacuum systems to remove polishing debris, suitable for polishing materials sensitive to water.

2. Describe the process of flat polishing step by step.

Surface Preparation

- Clean the surface to remove any contaminants.

- Level the surface using a grinding or sanding process.

Polishing

- Select the appropriate polishing pads and abrasives.

- Apply polishing slurry or lubricant to the surface.

- Use the flat polishing machine to apply pressure and motion to the surface.

- Monitor the polishing process and adjust parameters as needed.

Finishing

- Clean the surface to remove polishing debris.

- Check the surface for desired finish and flatness.

3. What are the common defects that can occur during flat polishing and how can they be prevented?

- Surface scratches: Can be caused by using too coarse abrasives, incorrect polishing pressure, or insufficient lubrication.

- Uneven polishing: Can be caused by uneven pressure distribution during polishing, improper pad selection, or misalignment of the polishing machine.

- Thermal damage: Can be caused by excessive heat build-up during polishing, which can lead to surface warping or discoloration.

- Chemical contamination: Can be caused by using inappropriate polishing slurries or cleaning agents, which can react with the surface material.

- Prevention measures: Use appropriate abrasives and polishing parameters, ensure proper lubrication, avoid excessive pressure, and monitor the polishing process closely.

4. How do you determine the correct polishing pressure for different materials?

- Consider the hardness and thickness of the material.

- Use a pressure gauge to measure and adjust the polishing pressure applied by the flat polishing machine.

- Start with a low pressure and gradually increase it until the desired surface finish is achieved.

- Monitor the surface for any signs of damage or deformation.

5. What are the different types of polishing pads used in flat polishing and their characteristics?

- Foam pads: Soft and flexible, used for delicate surfaces and initial polishing stages.

- Cloth pads: Durable and wear-resistant, used for general-purpose polishing.

- Felt pads: Compressible and conformable, used for polishing irregular surfaces.

- Diamond pads: Extremely hard and long-lasting, used for polishing hard materials like glass and ceramics.

6. How do you select the appropriate abrasive for flat polishing?

- Consider the material being polished and its hardness.

- Start with a coarse abrasive for initial stock removal.

- Gradually transition to finer abrasives to achieve the desired surface finish.

- Use a combination of abrasives for a balanced polishing process.

7. What safety precautions should be taken when operating a flat polishing machine?

- Wear appropriate safety gear, including gloves, eye protection, and a dust mask.

- Ensure the machine is properly grounded and has emergency stop controls.

- Keep the work area clean and free of tripping hazards.

- Handle and dispose of polishing debris properly to avoid environmental contamination.

8. What maintenance procedures are required for a flat polishing machine?

- Regularly clean the machine and its components.

- Lubricate moving parts as per manufacturer’s guidelines.

- Inspect and replace worn or damaged parts, such as polishing pads and abrasives.

- Calibrate the machine to ensure accurate polishing parameters.

9. What experience do you have in troubleshooting flat polishing issues?

I have encountered and resolved various flat polishing issues, such as uneven polishing, surface scratches, and thermal damage. I use a systematic approach to identify the root cause, including:

- Inspecting the surface and polishing machine.

- Adjusting polishing parameters, such as pressure, speed, and abrasives.

- Troubleshooting mechanical or electrical issues.

- Consulting with manufacturers or technical experts as needed.

10. What quality control measures do you implement to ensure the accuracy and consistency of flat polished surfaces?

- Establish clear specifications and flatness tolerances.

- Use precision measuring instruments, such as profilometers or interferometers, to measure surface flatness.

- Implement Statistical Process Control (SPC) techniques to monitor and improve polishing consistency.

- Regularly calibrate measuring equipment and perform verification checks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flat Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flat Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Flat Polishing

Involves using abrasive materials to smooth and polish flat surfaces such as concrete, marble, and granite

- Selecting and using appropriate abrasive materials and equipment

- Setting up and operating polishing machines

2. Surface Preparation

Preparing surfaces for polishing, including cleaning, grinding, and leveling

- Assessing the condition of surfaces

- Removing imperfections and debris

3. Maintenance and Calibration

Maintaining and calibrating polishing equipment to ensure optimal performance

- Inspecting and cleaning equipment

- Calibrating and adjusting settings

4. Quality Control

Ensuring the quality of polished surfaces meets customer specifications

- Inspecting finished surfaces for defects

- Taking corrective actions as needed

Interview Tips

To ace the interview, it’s crucial to prepare and showcase your skills and experience:

1. Research the Company

Explore the company’s website, social media, and industry news to gain insights into their business, culture, and recent developments. This will help you tailor your answers and demonstrate your interest.

2. Practice Your Answers

Anticipate common interview questions and prepare clear and concise answers that highlight your qualifications. Rehearse your delivery to ensure you articulate your points effectively.

3. Emphasize Relevant Experience

Describe your previous experiences in flat polishing, surface preparation, and quality control. Use specific examples and quantify your results to demonstrate your abilities.

4. Highlight Attention to Detail

In this role, attention to detail is paramount. Provide examples of how you have consistently exceeded quality standards and ensured customer satisfaction.

5. Demonstrate Safety Awareness

Safety is a critical aspect of flat polishing. Discuss your understanding of safety protocols, use of protective gear, and any certifications you hold.

6. Ask Informative Questions

Ask thoughtful questions about the company, the role, and the industry. This shows your interest, engagement, and eagerness to learn more.

7. Dress Professionally

First impressions matter. Dress professionally and arrive on time for your interview to convey a sense of respect and seriousness.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flat Polisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!