Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flat Surfacer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flat Surfacer so you can tailor your answers to impress potential employers.

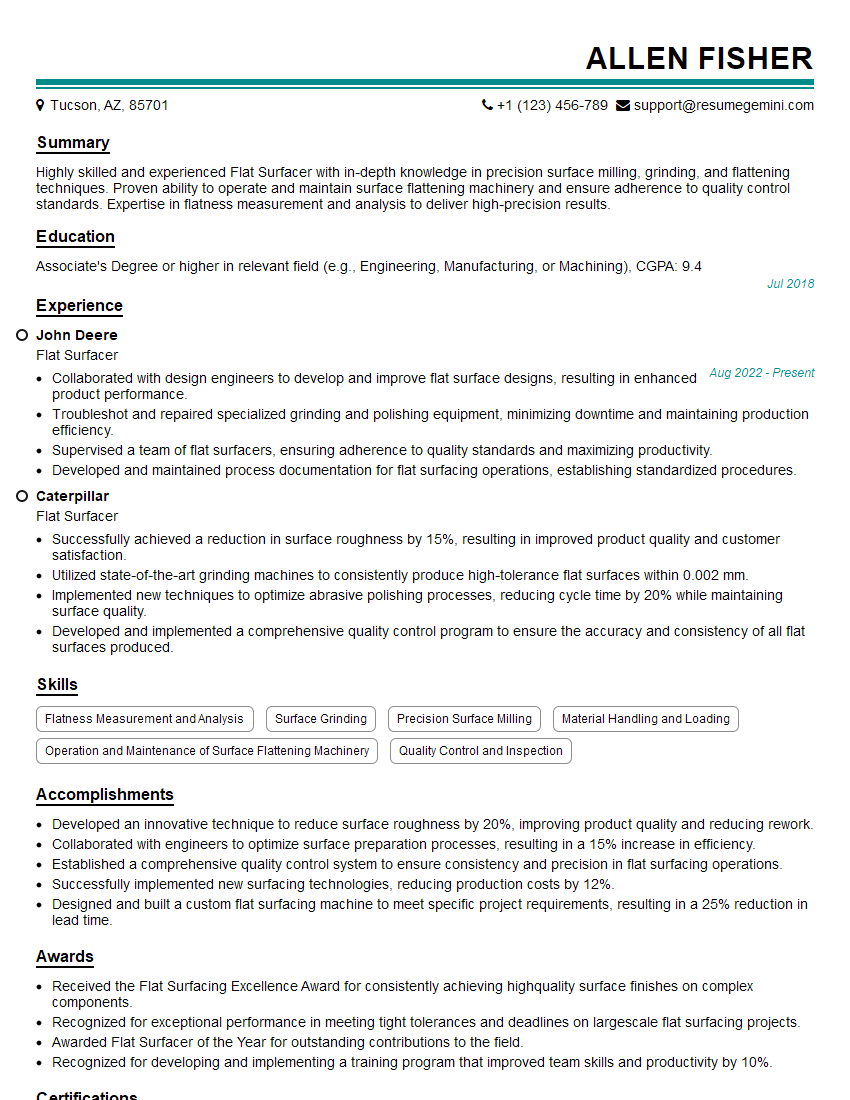

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flat Surfacer

1. What are the different types of flat surfacing machines and their applications?

There are several types of flat surfacing machines used for various applications, including:

- Wide Belt Sanders: Used for sanding and finishing surfaces of wood, metal, and composite materials.

- Edge Sanders: Designed to sand and finish the edges of workpieces.

- Planers: Used to remove material from the surface of workpieces, leveling and smoothing the surface.

- Surface Grinders: Employed in metalworking to grind and finish surfaces to precise tolerances.

- Rotary Table Sanders: Equipped with a rotating table for sanding and polishing curved or irregular surfaces.

2. What are the key factors to consider when selecting a flat surfacing machine?

When choosing a flat surfacing machine, the following factors should be taken into account:

- Type of material: Different machines are suitable for different materials, such as wood, metal, or plastic.

- Desired finish: The machine should be capable of producing the desired surface finish, such as rough sanding, fine sanding, or polishing.

- Workpiece size and shape: The machine should be able to accommodate the size and shape of the workpieces being processed.

- Accuracy and precision: The machine should provide the required level of accuracy and precision for the application.

- Productivity: The machine should have the appropriate speed and efficiency for the required production rate.

3. What are some common problems encountered in flat surfacing and how can they be resolved?

Some common problems in flat surfacing and their potential resolutions include:

- Scratches or uneven surface: Ensure the machine is properly set up, using appropriate abrasives and feed rates.

- Burning or discoloration: Reduce feed rate, use a lower grit abrasive, or ensure proper workpiece cooling.

- Chattering or vibration: Check machine alignment, balance the workpiece, or adjust the feed rate.

- Excessive dust: Use dust collection systems, properly maintain abrasives, and ensure workpiece is free of debris.

- Uneven thickness: Verify machine calibration, check workpiece clamping, or adjust the feed rate.

4. What are the safety precautions that must be observed when operating flat surfacing machines?

To ensure a safe working environment, it is essential to adhere to the following safety precautions:

- Proper PPE: Wear appropriate safety glasses, hearing protection, and gloves.

- Machine guarding: Ensure all machine guards and covers are in place and functioning correctly.

- Workpiece securing: Secure workpieces firmly to the machine using clamps or fixtures.

- Abrasive selection: Choose abrasives that are suitable for the material being processed and are in good condition.

- Maintenance: Regularly inspect and maintain the machine, ensuring proper lubrication and alignment.

5. What are your experiences in using different flat surfacing techniques?

Surface Grinding

- Experience using surface grinding machines for high-precision finishing of metal surfaces.

- Familiar with various grinding wheels, coolants, and techniques to achieve desired surface quality.

Wide Belt Sanding

- Expertise in operating wide belt sanders for sanding and finishing of large wooden surfaces.

- Proficient in selecting appropriate abrasives, feed rates, and sanding techniques to obtain desired results.

Planing

- Experience in using planers for leveling and smoothing wood surfaces.

- Understanding of different planer types, cutter head configurations, and feed rates to achieve desired thickness and surface quality.

6. How do you ensure the quality of flat surfaces produced?

To maintain the desired surface quality, I follow a systematic approach:

- Pre-Inspection: Inspect raw materials and workpieces for any defects or imperfections.

- Machine Setup: Ensure proper machine alignment, calibration, and abrasive selection.

- Process Control: Monitor feed rates, cutting depths, and temperatures throughout the process.

- Intermediate Inspection: Regularly inspect the workpiece during the process to identify any surface irregularities.

- Final Inspection: Conduct a thorough examination of the finished surface using appropriate measuring instruments and visual inspection.

7. What are your knowledge and experience with surface finishing standards?

I am familiar with various surface finishing standards, including:

- ISO 25178: Geometric Product Specifications (GPS) – Surface texture: Areal

- ANSI B46.1: Surface Texture

- JIS B 0601: Standard for the Representation of Surface Texture

- DIN EN ISO 13565: Geometrical Product Specifications (GPS) – Surface texture: Profile method

These standards provide guidelines for surface texture measurement, classification, and specification, enabling me to ensure the surface quality meets required standards.

8. How do you keep up with the latest advancements in flat surfacing technologies?

To stay updated with the latest advancements, I engage in continuous learning and professional development activities, such as:

- Industry Trade Shows: Attend exhibitions and conferences to learn about new technologies.

- Technical Publications: Read industry journals, research papers, and technical articles.

- Online Learning: Utilize online platforms and courses to enhance my knowledge.

- Workshops and Seminars: Participate in training sessions conducted by manufacturers and industry experts.

9. How do you handle complex or non-standard surface requirements?

When faced with complex or non-standard surface requirements, I approach the task with the following steps:

- Analysis: Assess the specific requirements and challenges.

- Research: Explore alternative techniques, materials, and processes.

- Collaboration: Consult with colleagues, engineers, or technical experts to gather additional insights.

- Testing: Conduct trials and experiments to determine the optimal solution.

- Adaptation: Modify or adapt existing techniques to meet the unique demands of the project.

10. What are your strengths and weaknesses as a Flat Surfacer?

Strengths

- Technical Expertise: Thorough understanding of flat surfacing principles, techniques, and equipment.

- Quality Focus: Committed to producing high-quality surfaces that meet industry standards.

- Problem-Solving Abilities: Skilled in identifying and resolving issues related to flat surfacing.

- Attention to Detail: Meticulous in ensuring accurate measurements and precise results.

Weaknesses

- Limited Experience with Specific Advanced Technologies: Open to expanding my knowledge in emerging areas.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flat Surfacer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flat Surfacer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Flat Surfacer is a highly skilled professional responsible for leveling and finishing concrete surfaces. They ensure the smoothness, flatness, and precision of concrete floors, walls, and other structures.

1. Surface Preparation

Prepare concrete surfaces by removing debris, curing compounds, and other materials that may interfere with the finishing process.

2. Leveling and Floating

Use a variety of tools and techniques to level and float the concrete surface to achieve a smooth and uniform finish.

3. Laser Screeding

Operate laser screeds to precisely level and smooth large concrete surfaces, ensuring optimal flatness and accuracy.

4. Troweling

Apply trowels to smooth and densify the concrete surface, enhancing its durability and resistance to wear and tear.

5. Grinding and Polishing

Use grinding and polishing equipment to remove imperfections and create a smooth, polished surface, as required for decorative or industrial applications.

6. Cleaning and Maintenance

Clean and maintain equipment, tools, and work areas to ensure a safe and efficient work environment.

Interview Tips

To ace the interview for a Flat Surfacer position, candidates should:

1. Research the Company and Industry

Familiarize themselves with the company’s history, values, and current projects. Also, research industry trends and best practices.

2. Highlight Relevant Experience and Skills

Emphasize their expertise in surface preparation, leveling, and finishing techniques. Showcase their ability to operate laser screeds, trowels, and other specialized equipment.

3. Demonstrate Safety Awareness

Highlight their understanding of safety protocols and their commitment to working safely on construction sites. Mention specific safety measures they have implemented in previous projects.

4. Prepare Example Portfolio and References

Bring a portfolio showcasing their best work, including photos or descriptions of successful projects. Provide references who can attest to their technical skills and work ethic.

5. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Why are you interested in this position?” and “What are your greatest strengths as a Flat Surfacer?”.

6. Dress Professionally and Arrive on Time

Make a positive first impression by dressing professionally and arriving at the interview on time. Punctuality and professionalism demonstrate respect for the interviewer’s time.

7. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to show their engagement and interest in the position. This demonstrates their enthusiasm and desire to learn more about the company.

8. Follow Up

Within 24 hours of the interview, send a thank-you note to the interviewer. Express gratitude for their time and reiterate their interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flat Surfacer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.