Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flattening Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flattening Press Operator so you can tailor your answers to impress potential employers.

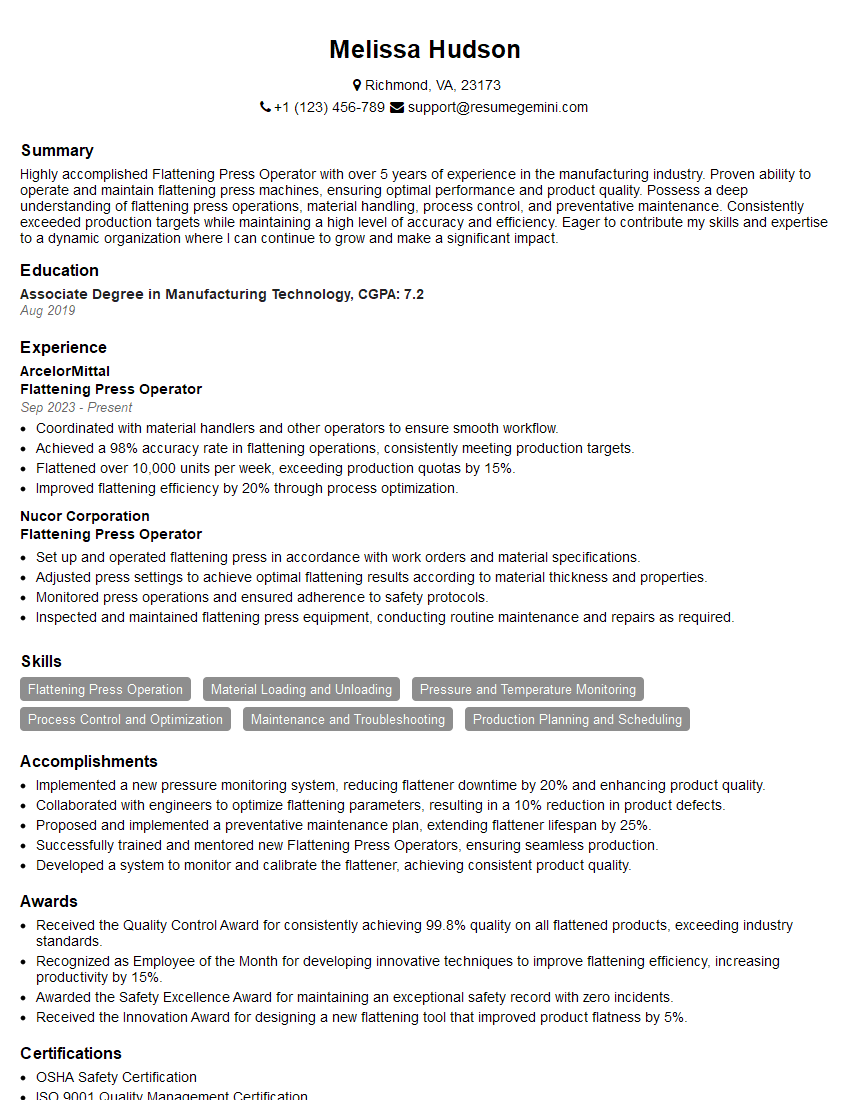

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flattening Press Operator

1. What are the different types of flattening press machines?

- Mechanical

- Hydraulic

- Pneumatic

2. What is the purpose of the flattening press?

- To flatten and smooth out materials

- To create a uniform thickness

- To remove wrinkles and creases

3. What are the safety precautions that must be taken when operating a flattening press?

- Ensure that the machine is properly guarded.

- Wear appropriate safety gear.

- Never place your hands under the press head.

- Be aware of the machine’s pressure and speed settings.

- Never leave the machine unattended while it is in operation.

4. What are the steps involved in operating a flattening press?

- Prepare the material by flattening it out and removing any wrinkles or creases.

- Set the machine’s pressure and speed settings.

- Place the material between the press head and the bed.

- Activate the press.

- Remove the flattened material from the machine.

5. What are the different types of materials that can be flattened using a flattening press?

- Fabrics

- Leather goods

- Paper

- Plastic

- Metal

6. What are the common problems that can occur when operating a flattening press?

- The machine may not be properly calibrated.

- The material may not be properly prepared.

- The pressure or speed settings may be incorrect.

- The machine may be defective.

It is important to be able to troubleshoot and resolve these problems in order to ensure the safe and efficient operation of the machine.

7. What is the importance of maintenance for a flattening press?

- To ensure the machine operates safely and efficiently.

- To prevent breakdowns and costly repairs.

- To extend the life of the machine.

8. What are the different types of maintenance tasks that need to be performed on a flattening press?

- Regular cleaning and lubrication.

- Checking and adjusting the machine’s pressure and speed settings.

- Inspecting the machine for any signs of damage or wear.

- Performing major repairs as needed.

9. What are the different skills and qualifications required to be a flattening press operator?

- Ability to operate a flattening press safely and efficiently.

- Knowledge of the different types of materials that can be flattened using a flattening press.

- Understanding of the maintenance requirements for a flattening press.

- Ability to troubleshoot and resolve problems that may occur during operation.

10. What are the career prospects for a flattening press operator?

Flattening press operators can advance to positions such as:

- Machine supervisor

- Production manager

- Quality control inspector

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flattening Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flattening Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Machine Operation and Maintenance

Operate and maintain the flattening press efficiently, ensuring optimal performance and quality output.

- Monitor and adjust machine settings (e.g., temperature, pressure, speed) to produce products according to specifications.

- Inspect and clean the press regularly, ensuring it is free from defects and maintaining safety protocols.

- Troubleshoot and resolve minor machine malfunctions, minimizing downtime and maximizing productivity.

2. Material Handling

Handle and prepare materials for processing, ensuring proper quality and adherence to specifications.

- Unload and load materials into the press, using appropriate techniques to prevent damage or contamination.

- Inspect materials for defects or irregularities, ensuring they meet standards before processing.

- Mark and identify materials as necessary, maintaining accurate production records and traceability.

3. Quality Control

Monitor and evaluate the quality of products produced, ensuring they adhere to established standards.

- Conduct regular inspections and measurements to verify dimensional accuracy, surface finish, and other quality attributes.

- Identify and record deviations from specifications, implementing corrective actions as needed.

- Maintain quality records and documentation, providing data for process improvement and customer satisfaction.

4. Safety and Compliance

Adhere to safety protocols and maintain a safe and compliant work environment.

- Wear appropriate personal protective equipment (PPE) and follow established safety procedures.

- Maintain a clean and organized work area, minimizing hazards and promoting efficiency.

- Report any safety concerns or incidents promptly to ensure a safe working environment.

Interview Tips

1. Research the Company and Industry

Gather information about the company’s background, products, services, and industry trends.

- Visit the company website, read industry news, and explore social media platforms to stay informed.

- Research the specific role and learn about the required skills, responsibilities, and experience.

2. Practice Common Interview Questions

Prepare for frequently asked interview questions by anticipating and practicing your responses.

- Practice describing your experience and skills, highlighting how they align with the job requirements.

- Prepare examples of your accomplishments and how you have contributed to previous teams or projects.

3. Highlight Transferable Skills

Even if you do not have direct experience as a Flattening Press Operator, emphasize transferable skills that are relevant to the role.

- Showcase your ability to operate and maintain machinery, handle materials, and ensure quality standards.

- Emphasize your attention to detail, problem-solving skills, and commitment to safety.

4. Be Confident and Enthusiastic

Project confidence and enthusiasm throughout the interview, demonstrating your interest in the role and the company.

- Maintain eye contact, speak clearly, and show genuine interest in the job and the interviewer.

- Be prepared to ask questions about the company, the role, and the industry, indicating your engagement and curiosity.

Next Step:

Now that you’re armed with the knowledge of Flattening Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Flattening Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini