Are you gearing up for a career in Flexo Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Flexo Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

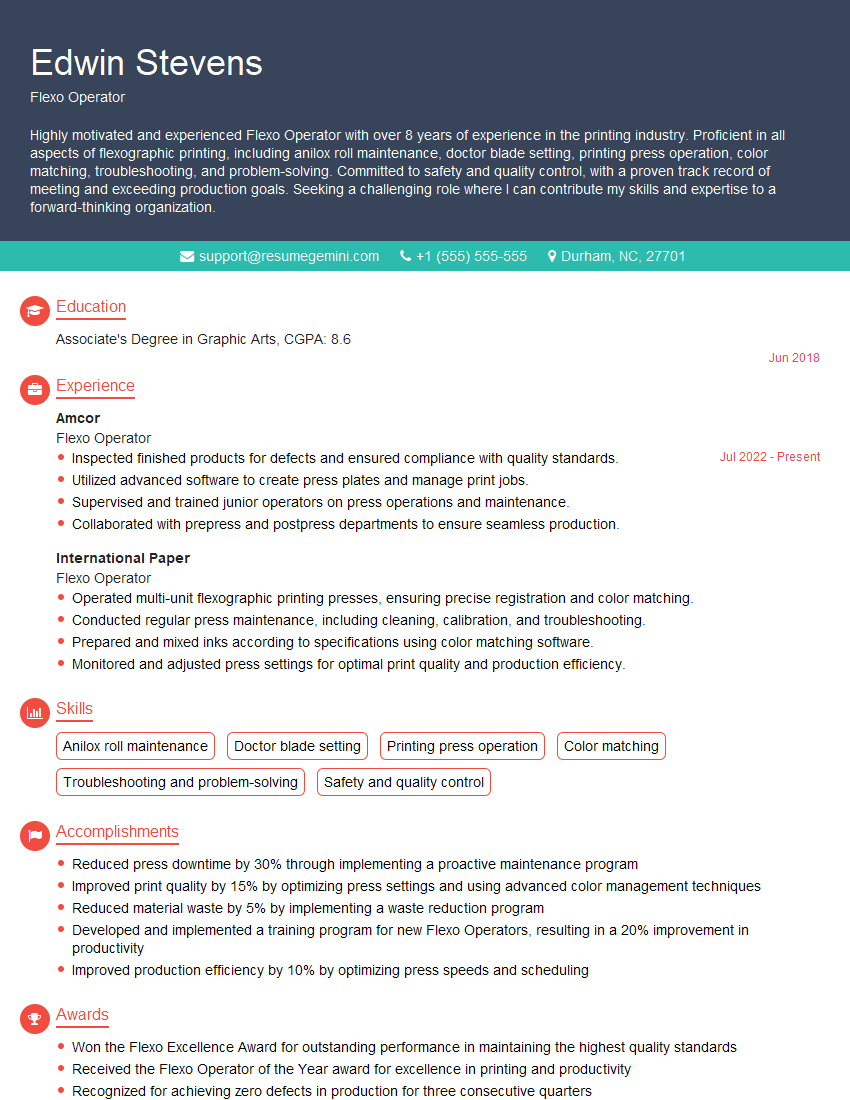

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flexo Operator

1. Explain the steps involved in setting up a flexographic printing press for a new job?

The steps involved in setting up a flexographic printing press for a new job include:

- Unloading and inspecting the printing plates

- Mounting the printing plates onto the press cylinders

- Setting the impression and register

- Loading the substrate into the press

- Adjusting the press speed and tension

- Running a test print and making any necessary adjustments

2. What are the different types of flexographic printing inks?

Solvent-based inks

- Advantages: Fast drying, good adhesion, vibrant colors

- Disadvantages: Flammable, hazardous to health, require special disposal

Water-based inks

- Advantages: Environmentally friendly, non-flammable, safe for food packaging

- Disadvantages: Slower drying, less vibrant colors, may require special coatings

UV-curable inks

- Advantages: Fast drying, high gloss, resistant to scratching and abrasion

- Disadvantages: Require special UV lamps, may be more expensive than other inks

3. What are the factors that affect the quality of flexographic printing?

The factors that affect the quality of flexographic printing include:

- The quality of the printing plates

- The type of ink used

- The press speed and tension

- The condition of the press

- The skill of the operator

4. What are the common problems that can occur during flexographic printing?

- Printing defects such as dot gain, slurring, and banding

- Ink problems such as foaming, skinning, and drying too slowly

- Press problems such as misregistration, web breaks, and vibration

5. How do you troubleshoot and resolve problems during flexographic printing?

To troubleshoot and resolve problems during flexographic printing, you need to:

- Identify the problem

- Determine the cause of the problem

- Implement a solution to the problem

- Test the solution to ensure that the problem has been resolved

6. What are the safety precautions that need to be taken when operating a flexographic printing press?

- Wear appropriate safety gear, including gloves, safety glasses, and a lab coat

- Keep the press area clean and free of debris

- Be aware of the moving parts of the press and keep hands clear

- Follow all manufacturer’s safety instructions

7. What is the role of a flexographic printing press operator?

The role of a flexographic printing press operator is to operate and maintain a flexographic printing press to produce high-quality printed products.

- Set up and operate the press

- Monitor the press during operation

- Troubleshoot and resolve problems

- Maintain the press

8. What are the skills and qualifications required to be a flexographic printing press operator?

- Knowledge of flexographic printing principles

- Experience operating a flexographic printing press

- Troubleshooting and problem-solving skills

- Good communication and interpersonal skills

- Ability to work independently and as part of a team

9. What are the career advancement opportunities for a flexographic printing press operator?

- Lead operator

- Supervisor

- Manager

- Technical support

- Sales

10. What is your favorite thing about working as a flexographic printing press operator?

My favorite thing about working as a flexographic printing press operator is the variety of work. Every day is different, and I get to learn new things all the time. I also enjoy the challenge of producing high-quality printed products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flexo Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flexo Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Flexo Operator is accountable for operating flexographic printing presses to create high-quality printed materials such as labels, packaging, and flexible films. Key responsibilities include:

1. Machine Operation

Operate flexographic printing presses to produce printed materials

- Set up and adjust printing presses according to job specifications

- Load and unload materials onto the press

- Monitor the printing process and make adjustments as needed

2. Quality Control

Ensure the quality of printed materials by:

- Inspecting printed materials for defects

- Making adjustments to the printing process to correct defects

- Maintaining accurate color and registration

3. Maintenance

Maintain printing presses and related equipment to ensure optimal performance and prevent breakdowns

- Perform routine maintenance tasks such as cleaning, lubrication, and adjustments

- Identify and troubleshoot mechanical problems

- Coordinate with mechanics to perform major repairs and upgrades

4. Other Responsibilities

In addition to the above, Flexo Operators may also:

- Train and supervise new operators

- Develop and implement new printing processes

- Work with customers to resolve printing issues

Interview Tips

Preparing for a Flexo Operator interview requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take some time to learn about the company and the specific Flexo Operator position. This will allow you to tailor your answers and show that you are genuinely interested in the opportunity.

- Visit the company website to learn about their products, services, and culture.

- Read industry publications and news articles to stay up-to-date on the latest trends in flexographic printing.

- Connect with current or former employees on LinkedIn to gain insights into the company and the position.

2. Practice Your Answers

Once you have a good understanding of the company and position, it’s time to practice your answers to common interview questions. This will help you feel more confident and articulate during the interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Use the STAR method to structure your answers and provide specific examples of your work.

- Practice your answers out loud in front of a mirror or with a friend or family member.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire. Make sure your clothes are clean, pressed, and fit well.

- For men, a suit or dress pants with a button-down shirt and tie is appropriate.

- For women, a skirt or pantsuit with a blouse or sweater is a good choice.

- Avoid wearing casual clothing such as jeans, t-shirts, or sneakers.

4. Be Punctual

Punctuality is essential for any job interview. Make sure to arrive at the interview location on time, or even a few minutes early. This shows that you are respectful of the interviewer’s time and that you are serious about the opportunity.

- Plan your route ahead of time and allow plenty of time for travel.

- If you are running late, call the interviewer as soon as possible to let them know.

- Do not be late for your interview without a valid excuse.

5. Be Enthusiastic and Positive

During the interview, it is important to be enthusiastic and positive about the opportunity. This means being excited to talk about your experience and skills, and demonstrating a genuine interest in the company and position.

- Smile, make eye contact, and speak clearly and confidently.

- Be passionate about your work and share examples of your successes.

- Avoid being negative or complaining about your previous job or experience.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Flexo Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.