Feeling lost in a sea of interview questions? Landed that dream interview for Flexographic Press Set-Up Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Flexographic Press Set-Up Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

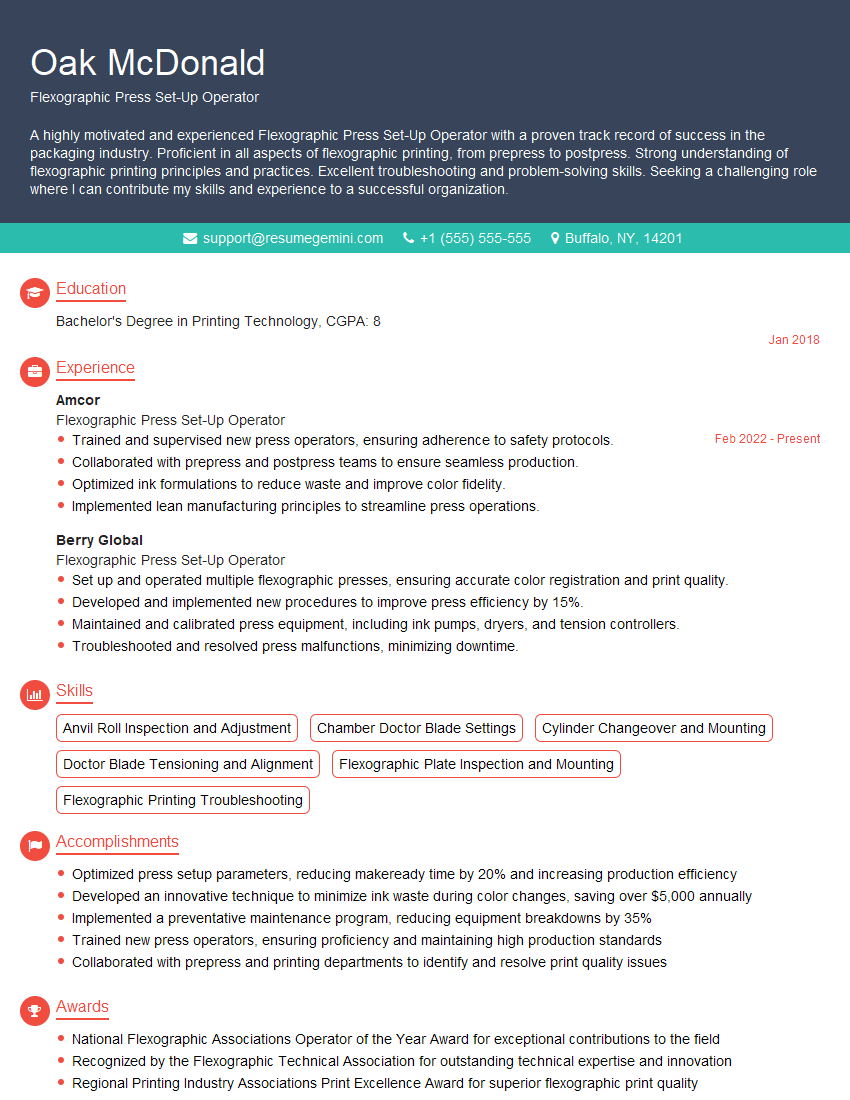

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flexographic Press Set-Up Operator

1. Describe the steps involved in setting up a flexographic press for a new print run.

– Review the print job specifications and materials. – Mount the printing plates on the press cylinders. – Set the ink fountains and adjust the ink flow to achieve the desired ink density. – Calibrate the press to ensure correct registration of the colors. – Run a test print to verify the color accuracy and print quality.

2. How do you handle variations in substrate thickness and absorbency?

Ink adjustments

- Adjust ink viscosity to improve ink transfer and prevent smearing.

- Modify ink density to compensate for substrate absorbency.

Press adjustments

- Adjust press speed to control ink drying time and prevent smudging.

- Calibrate press tension to ensure proper substrate feeding and registration.

3. Explain the factors that affect print quality in flexographic printing and how you optimize them.

– Plate quality: Inspect plates for defects and ensure proper etching depth. – Ink viscosity: Adjust ink viscosity to achieve the desired color density and flow characteristics. – Press settings: Calibrate press speed, tension, and register to prevent distortion and misalignment. – Substrate quality: Ensure substrate uniformity and surface smoothness. – Environmental factors: Control temperature and humidity to maintain ink stability and prevent drying issues.

4. Describe troubleshooting techniques for common flexographic printing defects, such as mottling and ghosting.

Mottling: Uneven distribution of ink on the substrate

- Check ink fountain and adjust ink flow.

- Inspect Anilox roll for damage or wear.

- Verify press speed and tension settings.

Ghosting: Secondary impression of an image

- Inspect printing plates for cracks or scratches.

- Calibrate press register to ensure proper plate alignment.

- Adjust ink tack to reduce dot gain and prevent image transfer.

5. Discuss the importance of maintaining press cleanliness and how you ensure it.

– Improved print quality: Clean presses prevent ink build-up and contamination, ensuring sharp and consistent printing. – Reduced maintenance downtime: Regular cleaning minimizes wear and tear on press components, extending their lifespan. – Enhanced safety: Clean presses reduce the risk of accidents and work-related injuries. – Increased productivity: Clean presses operate more efficiently, reducing setup and downtime, thereby increasing overall productivity.

6. Describe your experience with different types of flexographic inks and their applications.

– Water-based inks: Environmentally friendly, suitable for a wide range of substrates, require proper drying conditions. – Solvent-based inks: Durable, offer excellent color vibrancy, but require careful handling due to toxicity. – UV-curable inks: Quick-drying, provide high gloss and scratch resistance, require UV lamps for curing. – Specialty inks: Inks with unique properties, such as fluorescent, metallic, or thermal inks, used for specific applications.

7. How do you work with prepress and postpress departments to ensure a smooth production process?

– Effective communication: Establish clear communication channels to exchange information on job requirements and timelines. – Accurate file preparation: Review prepress proofs to ensure correct plate creation and print quality. – Proper finishing: Collaborate with postpress to determine the appropriate finishing processes, such as cutting, folding, and binding. – Problem resolution: Work together to identify and resolve any issues that arise during production, ensuring seamless transition between departments.

8. Explain the principles of flexographic printing and how it differs from other printing methods.

– Flexographic printing: Uses flexible printing plates made of rubber or polymer, transfers ink from a rotating plate to a substrate through an Anilox roll. – Differences from other methods: – Offset printing: Uses metal plates and multiple rollers to transfer ink, resulting in higher resolution and print quality. – Gravure printing: Uses etched cylinders to create recesses that hold ink, providing excellent detail and durability. – Digital printing: Uses digital files to print images directly onto a substrate, offering variable data and short print runs.

9. What are the key safety precautions to observe in a flexographic printing environment?

– Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs. – Maintain a clean and organized work area to prevent slipping and tripping hazards. – Ensure proper machine guarding and lockout/tagout procedures are followed. – Handle chemicals and inks safely, including proper disposal and storage. – Be aware of potential fire hazards and know the location of fire extinguishers.

10. How do you stay updated with the latest advancements in flexographic printing technology?

– Attend industry conferences and exhibitions. – Read trade publications and technical journals. – Participate in online forums and discussion groups. – Seek training and certification opportunities. – Network with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flexographic Press Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flexographic Press Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Flexographic Press Set-Up Operator plays a pivotal role in the printing industry by setting up and maintaining flexographic printing presses, ensuring optimal performance and quality output. Their key responsibilities encompass:

1. Press Setup and Operation

Preparing, installing, and adjusting printing plates, inks, and other consumables on the press

2. Quality Control

Conducting pre-press and post-press inspections to verify color accuracy, registration, and overall print quality

3. Troubleshooting and Maintenance

Identifying and resolving press malfunctions, performing routine maintenance, and adhering to safety protocols

4. Collaboration and Communication

Coordinating with press operators, quality control personnel, and supervisors to ensure smooth production

Interview preparation tips

To ace the interview for a Flexographic Press Set-Up Operator position, candidates should:

1. Research the Company and Industry

Gather information about the company’s products, services, and values, as well as the latest trends in flexographic printing.

2. Practice Common Interview Questions

Prepare for standard interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

3. Highlight Relevant Experience and Skills

Emphasize your experience in press setup, quality control, and troubleshooting, and quantify your accomplishments whenever possible.

4. Demonstrate Technical Proficiency

Discuss your knowledge of flexographic printing principles, different types of printing plates, and press maintenance procedures

5. Show Passion and Enthusiasm

Convey your interest in the printing industry and your eagerness to contribute to the company’s success.

6. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flexographic Press Set-Up Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.