Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Flexographic Printing Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

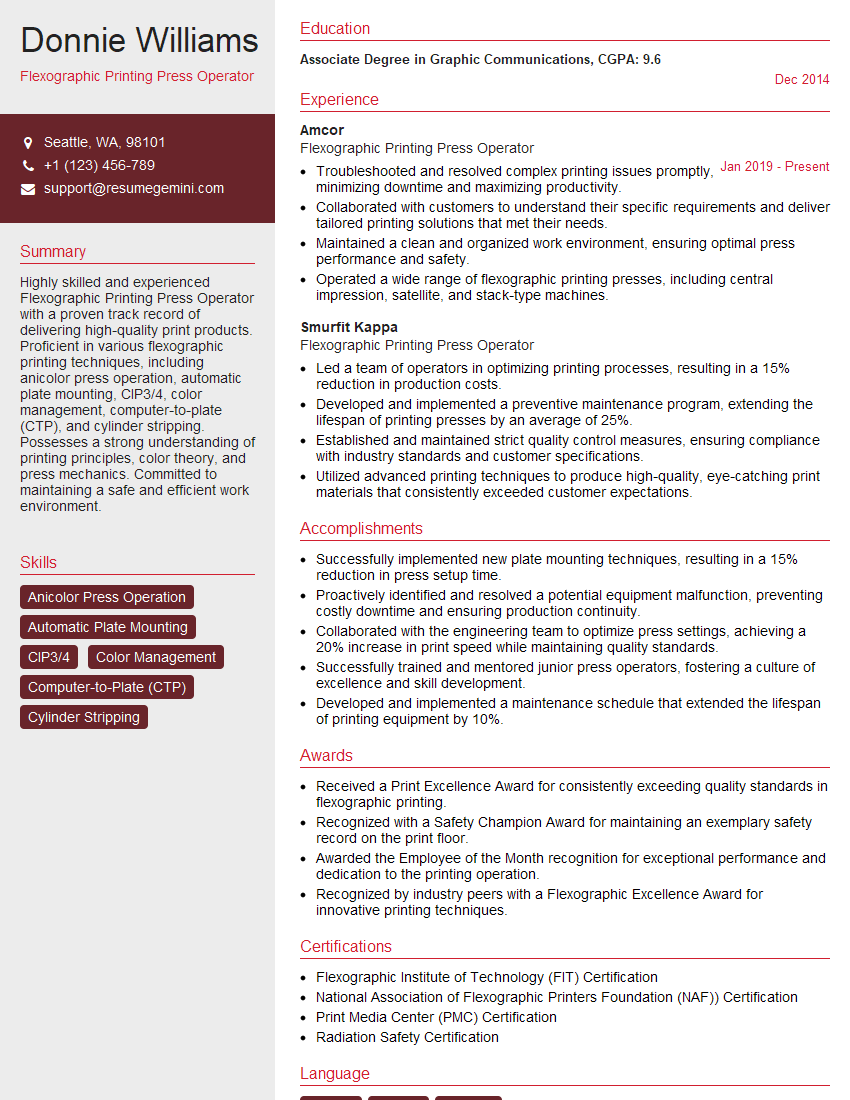

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flexographic Printing Press Operator

1. Describe the process of setting up a flexographic printing press.

The setup process for a flexographic printing press involves the following steps:

- Loading the press: The first step is to load the press with the substrate, which is the material being printed on. The substrate is fed into the press and secured in place.

- Preparing the plates: The flexographic printing plates are mounted on the printing cylinders. The plates are made of a flexible material, such as rubber or polymer, and are engraved with the desired image.

- Setting the ink: The ink is loaded into the ink fountain. The ink is then pumped to the printing cylinders.

- Setting the pressure: The pressure of the printing cylinders is adjusted to ensure that the ink is transferred properly to the substrate.

- Running the press: Once the press is set up, it is ready to be run. The press is started and the substrate is fed through the press.

2. How do you troubleshoot common problems that can occur during flexographic printing?

Troubleshooting ink problems

- If the ink is not transferring properly to the substrate, the pressure of the printing cylinders may need to be adjusted.

- If the ink is smearing, the viscosity of the ink may need to be adjusted.

- If the ink is drying too quickly, the temperature of the press may need to be adjusted.

Troubleshooting substrate problems

- If the substrate is wrinkling, the tension of the substrate may need to be adjusted.

- If the substrate is tearing, the speed of the press may need to be reduced.

- If the substrate is not feeding properly, the feed system may need to be adjusted.

Troubleshooting press problems

- If the press is vibrating, the press may need to be leveled.

- If the press is making noise, the bearings may need to be lubricated.

- If the press is not printing properly, the plates may need to be replaced.

3. What are the different types of flexographic printing plates?

There are two main types of flexographic printing plates:

- Digital plates: Digital plates are made using a digital imaging process. The image is created on a computer and then transferred to the plate. Digital plates are typically used for short-run printing jobs.

- Analog plates: Analog plates are made using a photoengraving process. The image is created on a film negative and then transferred to the plate. Analog plates are typically used for long-run printing jobs.

4. What is the difference between water-based and solvent-based inks?

Water-based inks and solvent-based inks are two different types of inks that are used in flexographic printing. The main difference between the two types of inks is the way that they dry.

- Water-based inks: Water-based inks are made with water as the solvent. They dry by evaporation of the water.

- Solvent-based inks: Solvent-based inks are made with a solvent as the solvent. They dry by evaporation of the solvent.

5. What are the different types of flexographic printing presses?

There are two main types of flexographic printing presses:

- Central impression presses: Central impression presses are the most common type of flexographic printing press. In a central impression press, the printing cylinders are arranged around a central impression cylinder.

- Satellite presses: Satellite presses are a newer type of flexographic printing press. In a satellite press, the printing cylinders are arranged around a central ink drum.

6. What are the advantages of flexographic printing over other printing methods?

- High quality: Flexographic printing can produce high-quality prints with fine detail.

- Fast printing speeds: Flexographic printing presses can print at high speeds, making them ideal for long-run printing jobs.

- Wide range of substrates: Flexographic printing can be used to print on a wide range of substrates, including paper, plastic, metal, and fabric.

- Low cost: Flexographic printing is a relatively low-cost printing method.

7. What are the different types of dies used in flexographic printing?

- Rotary dies: Rotary dies are used to diecut shapes out of the substrate. Rotary dies are mounted on a rotating cylinder and are used in conjunction with a cutting anvil.

- Flat dies: Flat dies are used to diecut shapes out of the substrate. Flat dies are mounted on a flat surface and are used in conjunction with a cutting press.

- Combination dies: Combination dies are a combination of rotary dies and flat dies. Combination dies are used to diecut shapes out of the substrate and to create creases.

8. What are the different types of finishing processes used in flexographic printing?

- Coating: Coating is a process of applying a protective or decorative layer to the printed substrate. Coatings can be applied by a variety of methods, including spraying, brushing, and dipping.

- Laminating: Laminating is a process of bonding two or more layers of substrate together. Laminating can be used to improve the strength, durability, and appearance of the printed substrate.

- Die cutting: Die cutting is a process of cutting shapes out of the printed substrate. Die cutting can be used to create labels, boxes, and other products.

- Folding and gluing: Folding and gluing is a process of folding and gluing the printed substrate to create a finished product. Folding and gluing can be used to create boxes, brochures, and other products.

9. What are the different types of quality control checks that are performed in flexographic printing?

- Visual inspection: Visual inspection is a simple but effective way to check the quality of a printed product. Visual inspection can be used to identify defects such as scratches, smudges, and misprints.

- Densitometry: Densitometry is a method of measuring the density of ink on a printed product. Densitometry can be used to ensure that the ink is applied evenly and that the printed product meets the desired specifications.

- Colorimetry: Colorimetry is a method of measuring the color of a printed product. Colorimetry can be used to ensure that the printed product matches the desired color specifications.

- Gloss measurement: Gloss measurement is a method of measuring the amount of gloss on a printed product. Gloss measurement can be used to ensure that the printed product has the desired level of gloss.

10. What are the different types of safety precautions that must be taken when operating a flexographic printing press?

- Wear appropriate clothing: Loose clothing and jewelry can get caught in the press and cause injury. Wear close-fitting clothing and remove all jewelry before operating the press.

- Keep hands away from moving parts: Keep your hands away from the printing cylinders, gears, and other moving parts of the press. These parts can cause serious injury.

- Use caution when working with sharp objects: Dies and other sharp objects can cause cuts and other injuries. Use caution when handling sharp objects and wear gloves when necessary.

- Be aware of your surroundings: Be aware of your surroundings and be careful not to trip over cords or other objects. Pay attention to the movement of the press and other equipment.

- Follow all safety procedures: Follow all safety procedures and guidelines that are established for the press. These procedures are designed to protect you and others from injury.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flexographic Printing Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flexographic Printing Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flexographic Printing Press Operators are responsible for operating, monitoring, and maintaining a flexographic printing press. They ensure that the press is operating correctly and that the printed materials meet the required quality standards.

1. Operating the Press

Press operators are responsible for loading the press with paper, ink, and plates. They also need to adjust the press settings to ensure that the printed materials meet the required specifications.

- Loading and unloading paper rolls

- Adjusting press settings, such as speed, pressure, and temperature

- Monitoring the press for any problems

2. Maintaining the Press

Press operators are also responsible for maintaining the press. This includes cleaning the press, lubricating the moving parts, and making minor repairs.

- Cleaning the press

- Lubricating the moving parts

- Making minor repairs

3. Troubleshooting

Press operators need to be able to troubleshoot any problems that may occur with the press. This may involve identifying the source of the problem and making the necessary repairs.

- Identifying the source of the problem

- Making the necessary repairs

4. Quality Control

Press operators are responsible for ensuring that the printed materials meet the required quality standards. This may involve inspecting the printed materials for any defects and making adjustments to the press settings as needed.

- Inspecting the printed materials for any defects

- Making adjustments to the press settings as needed

Interview Tips

Preparing for a job interview can be daunting. However, by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before you go to the interview, take some time to research the company and the position for which you are applying. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on its website and social media pages. You can also talk to people who work at the company or read articles about it in the news.

- Visit the company’s website and social media pages

- Talk to people who work at the company

- Read articles about the company in the news

2. Practice Answering Common Interview Questions

There are certain questions that are commonly asked in job interviews. By practicing answering these questions, you can increase your confidence and deliver more polished responses during the interview. Some common interview questions include:

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “Why should we hire you?”

3. Be Yourself

It is important to be yourself during the interview. The interviewer wants to get to know the real you. So, don’t try to be someone you’re not. Just relax and let your personality shine through.

- Don’t try to be someone you’re not

- Relax and let your personality shine through

4. Dress Appropriately

First impressions matter. So, make sure you dress appropriately for the interview. This means wearing clean, pressed clothes that are appropriate for the company culture.

- Wear clean, pressed clothes

- Dress appropriately for the company culture

5. Be Punctual

Punctuality is important for any job interview. Arrive at the interview on time, or even a few minutes early. This shows the interviewer that you are respectful of their time.

- Arrive at the interview on time, or even a few minutes early

- Plan your route to the interview in advance

6. Follow Up

After the interview, take the time to follow up with the interviewer. This could involve sending a thank-you note or email. Following up shows the interviewer that you are interested in the position and that you appreciate their time.

- Send a thank-you note or email

- Follow up with the interviewer about the next steps in the hiring process

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Flexographic Printing Press Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Flexographic Printing Press Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.