Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Floatman interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Floatman so you can tailor your answers to impress potential employers.

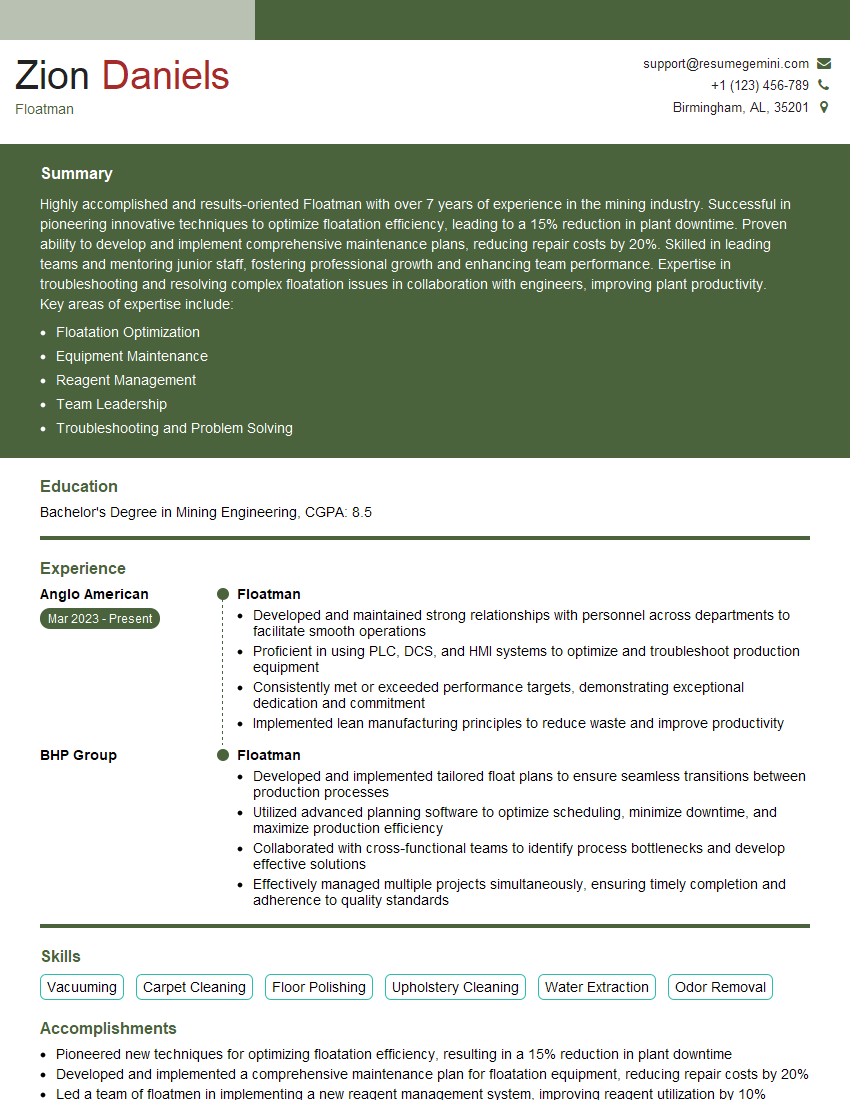

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Floatman

1. How do you ensure the accuracy and reliability of measured data during float glass production?

To ensure accuracy and reliability of measured data during float glass production, I follow these steps:

- Calibration and maintenance of measuring equipment: Regularly calibrate and maintain all measuring instruments, including thickness gauges, temperature sensors, and flow meters, to ensure they meet industry standards.

- Establishing calibration procedures: Implement and adhere to documented calibration procedures to ensure consistency and traceability of measurements.

2. Describe the methods you employ to monitor and control the glass temperature during the float process.

Monitoring Glass Temperature:

- Pyrometers: Use high-precision pyrometers to measure the glass temperature at various points throughout the process.

- Thermocouples: Insert thermocouples into the glass to monitor temperature gradients and ensure uniform heating.

Controlling Glass Temperature:

- Burner system: Adjust the burner system to regulate the heat input and maintain the desired temperature profile.

- Cooling zone: Optimize the cooling zone to gradually reduce the glass temperature and prevent thermal stress.

3. Explain how you handle and resolve process deviations in the float line, ensuring product quality.

To handle and resolve process deviations in the float line, I follow this approach:

- Identify the deviation: Promptly detect and identify any deviations from quality parameters using monitoring systems and visual inspections.

- Determine the root cause: Analyze the process data, equipment status, and environmental factors to determine the underlying cause of the deviation.

- Implement corrective actions: Develop and implement corrective actions based on the root cause analysis, such as adjusting process settings, replacing faulty equipment, or implementing new procedures.

- Monitor and verify: Closely monitor the process after implementing corrective actions to ensure they are effective and maintain product quality.

4. Describe the safety precautions you prioritize during float glass production and inspection.

Safety is paramount in float glass production and inspection. I prioritize the following precautions:

- Personal protective equipment: Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and heat-resistant clothing.

- Hazard identification and risk assessment: Identify and assess potential hazards throughout the process and implement appropriate control measures.

- Safe handling practices: Ensure safe handling of glass sheets, using proper lifting techniques and protective equipment.

- Regular inspections: Conduct regular inspections of equipment, work areas, and safety systems to maintain a safe working environment.

5. Explain how you ensure the dimensional accuracy and surface quality of float glass.

To ensure the dimensional accuracy and surface quality of float glass, I implement these measures:

- Thickness control: Monitor and control the thickness of the glass using precision measuring devices, such as thickness gauges and laser scanners.

- Flatness control: Inspect the flatness of the glass using optical methods, such as interferometers, to ensure it meets specifications.

- Surface quality inspection: Perform thorough surface inspections to identify and remove any defects, such as scratches, bubbles, or inclusions.

6. Discuss your experience in optimizing the float glass production process for efficiency.

To optimize the float glass production process for efficiency, I have implemented the following strategies:

- Process analysis: Analyzed the production process to identify bottlenecks and areas for improvement.

- Equipment upgrades: Recommended and implemented upgrades to equipment, such as faster cutting lines and more efficient burners, to increase productivity.

- Process parameter optimization: Adjusted process parameters, such as temperature and cooling rates, to reduce cycle times and improve product quality.

- Staff training: Provided training to operators on best practices and process optimization techniques.

7. Describe the role of sensors and automation in improving the float glass production process.

Sensors and automation play a vital role in improving the float glass production process:

- Process monitoring: Sensors continuously monitor process parameters, such as temperature, pressure, and flow rates, providing real-time data for analysis and control.

- Automated control: Automation systems adjust process parameters in response to sensor data, ensuring consistent production conditions and reducing the risk of deviations.

- Data analysis: Sensors generate large amounts of data, which can be analyzed to identify trends, predict failures, and optimize the process.

8. How do you maintain and troubleshoot the cooling system used in the float glass process?

To maintain and troubleshoot the cooling system used in the float glass process, I follow these steps:

- Preventive maintenance: Regularly inspect and service the cooling system components, including chillers, heat exchangers, and pumps.

- Temperature monitoring: Monitor the cooling system temperatures at various points to ensure proper operation and prevent overheating.

- Troubleshooting: In case of malfunctions, diagnose the problem by analyzing system data, checking for leaks, and inspecting components. Implement appropriate repairs or adjustments to restore the system’s functionality.

9. Explain your understanding of the annealing process in float glass production.

Annealing is a critical process in float glass production, which involves controlled cooling to remove internal stresses and improve the glass’s strength and durability:

- Temperature control: The glass is gradually cooled through a series of controlled temperature zones, allowing the internal stresses to relax.

- Cooling rate optimization: The cooling rate is carefully controlled to prevent thermal shock and ensure the removal of stresses without inducing new ones.

10. Describe how you ensure the environmental compliance of the float glass production facility.

To ensure environmental compliance of the float glass production facility, I implement the following measures:

- Emissions monitoring: Monitor emissions from the production process, such as particulate matter and sulfur dioxide, to comply with regulatory limits.

- Waste management: Implement a comprehensive waste management plan to minimize and properly dispose of hazardous and non-hazardous waste generated during production.

- Resource conservation: Optimize resource consumption, such as energy and water, through efficient process design and equipment upgrades.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Floatman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Floatman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Floatmen are crucial members of a manufacturing or production team, responsible for maintaining smooth operations. Their key job responsibilities include:

1. Production Support

- Assist production operators on multiple lines or machines

- Monitor equipment and ensure optimal performance

2. Material Handling

- Transport raw materials, work-in-progress, and finished goods within the facility

- Load and unload materials from equipment and vehicles

3. Quality Control

- Perform basic quality checks on products and materials

- Report any defects or deviations to supervisors

4. Housekeeping and Maintenance

- Maintain a clean and organized work area

- Perform minor maintenance tasks, such as cleaning equipment and changing filters

Interview Tips

To ace a Floatman interview, candidates should:

1. Research the Company and Position

- Visit the company website to learn about its products, services, and culture

- Review the job description and identify specific requirements

2. Highlight Relevant Skills and Experience

- Emphasize previous experience in manufacturing, production, or material handling

- Showcase technical skills related to equipment operation and maintenance

3. Prepare for Technical Questions

- Practice answering questions about basic equipment setup and troubleshooting

- Be prepared to discuss quality control procedures and safety protocols

4. Show Enthusiasm and Flexibility

- Convey a positive attitude and a strong work ethic

- Demonstrate a willingness to work in a dynamic and rapidly changing environment

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Floatman interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!