Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Floor Covering Printer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

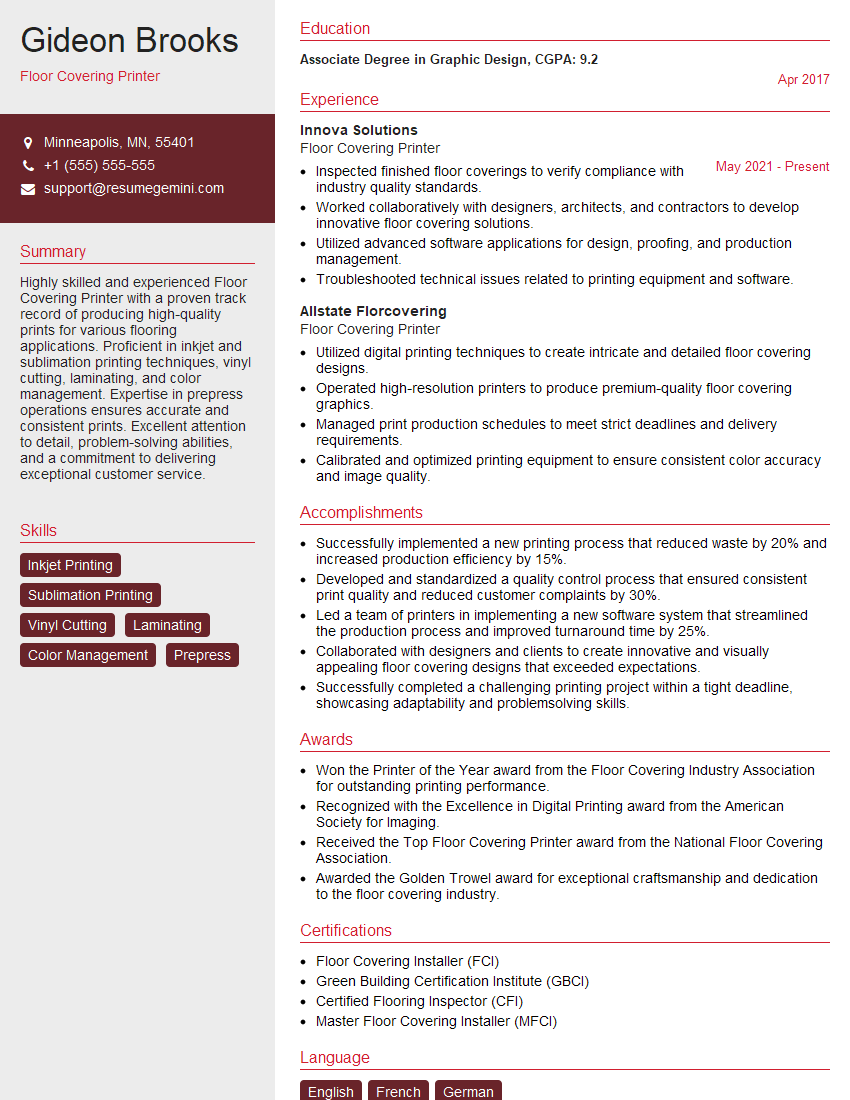

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Floor Covering Printer

1. What are the different types of floor covering printing presses?

- Gravure printing press

- Flexographic printing press

- Offset printing press

- Digital printing press

2. What is the difference between a gravure printing press and a flexographic printing press?

Gravure printing press

- Uses a metal cylinder engraved with the printing image

- The engraved cylinder is inked and then transferred to the paper or other substrate

- Produces high-quality prints with fine details

Flexographic printing press

- Uses a flexible printing plate made of rubber or plastic

- The printing plate is inked and then transferred to the paper or other substrate

- Produces good-quality prints at high speeds

3. What are the different types of inks used in floor covering printing?

- Water-based inks

- Solvent-based inks

- UV-curable inks

- Latex inks

4. What are the different types of substrates used in floor covering printing?

- Paper

- Cardboard

- Vinyl

- Carpet

- Tile

5. What are the different types of finishing processes used in floor covering printing?

- Coating

- Laminating

- Die-cutting

- Embossing

- Foil stamping

6. What are the different types of quality control checks that need to be performed in floor covering printing?

- Color matching

- Print registration

- Substrate quality

- Ink coverage

- Finish quality

7. What are the different types of safety precautions that need to be taken when operating a floor covering printing press?

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs

- Keep the work area clean and organized

- Be aware of the location of all emergency stops and exits

- Follow all safety instructions provided by the manufacturer

- Never operate a press that is not in good working condition

8. What are the different types of maintenance tasks that need to be performed on a floor covering printing press?

- Daily maintenance tasks, such as cleaning the press and checking the oil levels

- Weekly maintenance tasks, such as lubricating the press and inspecting the belts

- Monthly maintenance tasks, such as changing the ink filters and cleaning the print heads

- Yearly maintenance tasks, such as overhauling the press and replacing major components

9. What are the different types of troubleshooting skills that are required for a floor covering printer?

- The ability to identify and fix common printing problems, such as color matching issues, print registration problems, and substrate quality issues

- The ability to use diagnostic tools to troubleshoot more complex problems

- The ability to work with other members of the production team to resolve problems

- The ability to learn new troubleshooting techniques as new technologies are introduced

10. What are the different types of customer service skills that are required for a floor covering printer?

- The ability to communicate effectively with customers to understand their needs

- The ability to answer customer questions and provide technical support

- The ability to resolve customer complaints and build strong relationships

- The ability to work as part of a team to provide excellent customer service

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Floor Covering Printer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Floor Covering Printer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Floor Covering Printer is responsible for the production of high-quality floor covering products using specialized printing equipment. Their key responsibilities include:

1. Pre-Press Activities

Ensuring accurate pre-press preparation of artwork, including managing color correction, image manipulation, and layout design

2. Printing Process

Operating specialized printing machinery, such as rotogravure or digital printers, to create floor covering products based on design specifications

Monitoring and maintaining printing parameters to achieve optimal print quality and consistency

3. Post-Press Operations

Inspecting printed materials for defects and ensuring adherence to quality standards

Performing finishing techniques, such as laminating, embossing, or cutting, to create the desired product

4. Equipment Maintenance

Conducting regular maintenance and cleaning of printing equipment to prevent breakdowns and ensure optimal performance

Troubleshooting and resolving printing issues to minimize downtime

5. Material Handling

Handling and managing raw materials, such as inks, films, and substrates, to ensure efficient production

Storing and organizing finished products to maintain inventory

Interview Tips

Preparing for an interview for a Floor Covering Printer position requires a thorough understanding of the role and its responsibilities. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and industry reputation

Research the specific role and its requirements to tailor your answers during the interview

2. Highlight Your Technical Skills

Emphasize your expertise in operating printing equipment, including your knowledge of print processes and ink formulations

Provide examples of how you have used your technical skills to solve printing challenges

3. Showcase Your Attention to Detail

Stress your ability to focus on accuracy and precision in all aspects of your work, from pre-press to post-press operations

Discuss your methods for ensuring quality control and identifying potential defects

4. Demonstrate Your Problem-Solving Abilities

Share examples of how you have successfully resolved printing issues or optimized production processes

Explain your approach to troubleshooting and your ability to find solutions quickly

5. Prepare Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement

Prepare questions related to the company’s printing technology, production timelines, or industry trends

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Floor Covering Printer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!