Feeling lost in a sea of interview questions? Landed that dream interview for Floor Grinder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Floor Grinder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

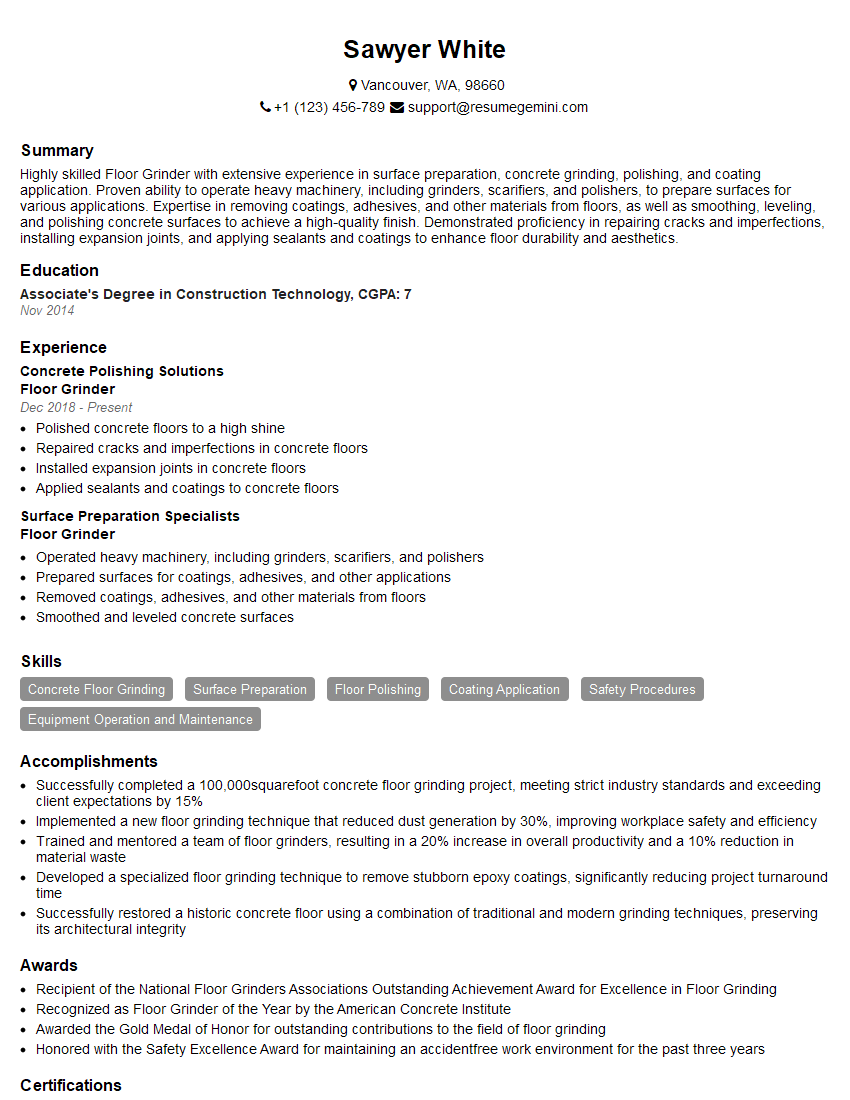

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Floor Grinder

1. What are the different types of floor grinding machines and their applications?

- Single-head grinders are the most common type of floor grinder. They have a single grinding head that rotates at a high speed to remove material from the floor. Single-head grinders are ideal for small to medium-sized projects, such as grinding concrete or removing old paint or glue from a floor.

- Double-head grinders have two grinding heads that rotate in opposite directions. This allows them to remove material from the floor more quickly and efficiently than single-head grinders. Double-head grinders are ideal for large projects, such as grinding concrete or terrazzo floors.

- Planetary grinders have multiple grinding heads that rotate around a central axis. This allows them to remove material from the floor very quickly and evenly. Planetary grinders are ideal for large projects, such as grinding concrete or marble floors.

2. What are the different types of abrasives used in floor grinding and their applications?

Diamond abrasives

- Diamond abrasives are the most durable and longest-lasting type of abrasive. They are ideal for grinding hard materials, such as concrete or stone.

- Diamond abrasives are available in a variety of grits, from coarse to fine. The grit size of the abrasive will determine the smoothness of the finished surface.

Ceramic abrasives

- Ceramic abrasives are less durable than diamond abrasives, but they are also less expensive. They are ideal for grinding softer materials, such as wood or plastic.

- Ceramic abrasives are also available in a variety of grits, from coarse to fine.

Metal abrasives

- Metal abrasives are the least durable type of abrasive, but they are also the least expensive. They are ideal for grinding soft materials, such as paper or fabric.

- Metal abrasives are available in a variety of grits, from coarse to fine.

3. What are the safety precautions that should be taken when operating a floor grinder?

- Wear appropriate safety gear, including a hard hat, safety glasses, earplugs, and gloves.

- Make sure the floor grinder is properly grounded.

- Inspect the floor grinder before each use to make sure it is in good working condition.

- Never operate a floor grinder on a wet floor.

- Be aware of your surroundings and keep others away from the work area.

- Follow the manufacturer’s instructions for operating the floor grinder.

4. How do you level a concrete floor using a floor grinder?

- Start by grinding the high spots on the floor. Use a coarse grit abrasive to remove the high spots quickly.

- Once the high spots have been removed, switch to a finer grit abrasive and grind the entire floor surface. This will help to smooth out the floor and remove any unevenness.

- Repeat step 2 until the floor is level. You can check the level of the floor using a level or a straightedge.

5. How do you remove old paint or glue from a floor using a floor grinder?

- Start by grinding the old paint or glue using a coarse grit abrasive. This will help to break up the old finish and make it easier to remove.

- Once the old finish has been broken up, switch to a finer grit abrasive and grind the floor surface until the old finish has been completely removed.

- Vacuum the floor to remove any dust or debris.

6. How do you polish a concrete floor using a floor grinder?

- Start by grinding the concrete floor using a coarse grit abrasive. This will help to remove any unevenness in the floor surface.

- Once the floor surface has been ground, switch to a finer grit abrasive and grind the floor surface again. This will help to smooth out the floor and remove any scratches.

- Repeat step 2 until the floor surface is smooth and polished. You can check the smoothness of the floor by running your hand over the surface.

7. What are the common problems that can occur when operating a floor grinder?

- The floor grinder is not properly grounded. This can cause the grinder to shock the operator.

- The floor grinder is not properly maintained. This can cause the grinder to overheat or break down.

- The operator is not properly trained. This can lead to accidents or injuries.

- The wrong type of abrasive is being used. This can damage the floor surface.

- The floor grinder is being used incorrectly. This can also damage the floor surface.

8. How do you troubleshoot a floor grinder that is not working properly?

- Check to make sure that the floor grinder is properly plugged in.

- Check to make sure that the floor grinder is properly grounded.

- Check to make sure that the circuit breaker for the floor grinder is not tripped.

- Check to make sure that the power cord for the floor grinder is not damaged.

- Check to make sure that the brushes in the floor grinder are not worn out.

- Check to make sure that the bearings in the floor grinder are not damaged.

9. What are the maintenance tasks that should be performed on a floor grinder?

- Clean the floor grinder after each use.

- Inspect the floor grinder before each use to make sure it is in good working condition.

- Lubricate the floor grinder according to the manufacturer’s instructions.

- Replace the brushes in the floor grinder when they become worn out.

- Replace the bearings in the floor grinder when they become damaged.

10. What are the benefits of using a floor grinder?

- Floor grinders can be used to level concrete floors.

- Floor grinders can be used to remove old paint or glue from floors.

- Floor grinders can be used to polish concrete floors.

- Floor grinders can be used to remove unevenness from floors.

- Floor grinders can be used to create a smooth, polished surface on floors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Floor Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Floor Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Floor Grinders are responsible for the preparation, maintenance, and resurfacing of floors in buildings and other structures. They may work on various types of floors, including concrete, tile, hardwood, and epoxy. Their key responsibilities include:1. Floor Preparation

Prepare floors for grinding by removing existing finishes, adhesives, or coatings using grinders, scarifiers, or other specialized equipment. Ensuring the floor is level, smooth, and free of debris or imperfections.

2. Grinding and Polishing

Operate grinders to remove the top layer of concrete or other flooring materials, creating a smooth and uniform surface. Utilizing various grits and techniques to achieve the desired finish, from rough grinding for leveling to fine polishing for a glossy appearance.

3. Floor Sealing and Coating

Apply sealants or coatings to protect the newly ground or polished floors. Using brushes, rollers, or sprayers to evenly distribute the protective layer, ensuring a durable and long-lasting finish.

4. Equipment Maintenance

Maintain and calibrate grinding equipment, including grinders, dust collectors, and polishers. Regularly inspect and perform necessary repairs or adjustments to ensure optimal performance and safety.

5. Safety and Compliance

Adhere to safety protocols and industry regulations related to grinding operations. Wear appropriate protective gear, such as masks, gloves, and earplugs, while operating equipment. Follow established guidelines for dust control and waste disposal.

Interview Tips

To ace an interview for a Floor Grinder position, it is essential to prepare thoroughly and showcase your skills and experience. Here are some tips to help you succeed:1. Research the Company and Position

Familiarize yourself with the company’s industry, history, and values. Research the specific role and its responsibilities to demonstrate your interest and understanding of the position.

2. Highlight Relevant Skills and Experience

Emphasize your experience in floor preparation, grinding, polishing, and sealing techniques. Quantify your accomplishments whenever possible, using specific metrics to showcase the impact of your work.

3. Prepare for Technical Questions

Anticipate questions about your knowledge of grinding equipment, safety protocols, and different types of floor finishes. Review industry standards and be prepared to discuss your understanding of the latest technologies.

4. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role,” and “What are your strengths and weaknesses.” Practice articulating your skills, experience, and motivations.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive at the interview on time to demonstrate your respect for the company and the position. Maintain a positive and enthusiastic attitude throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Floor Grinder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!