Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Floor Surfacer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Floor Surfacer so you can tailor your answers to impress potential employers.

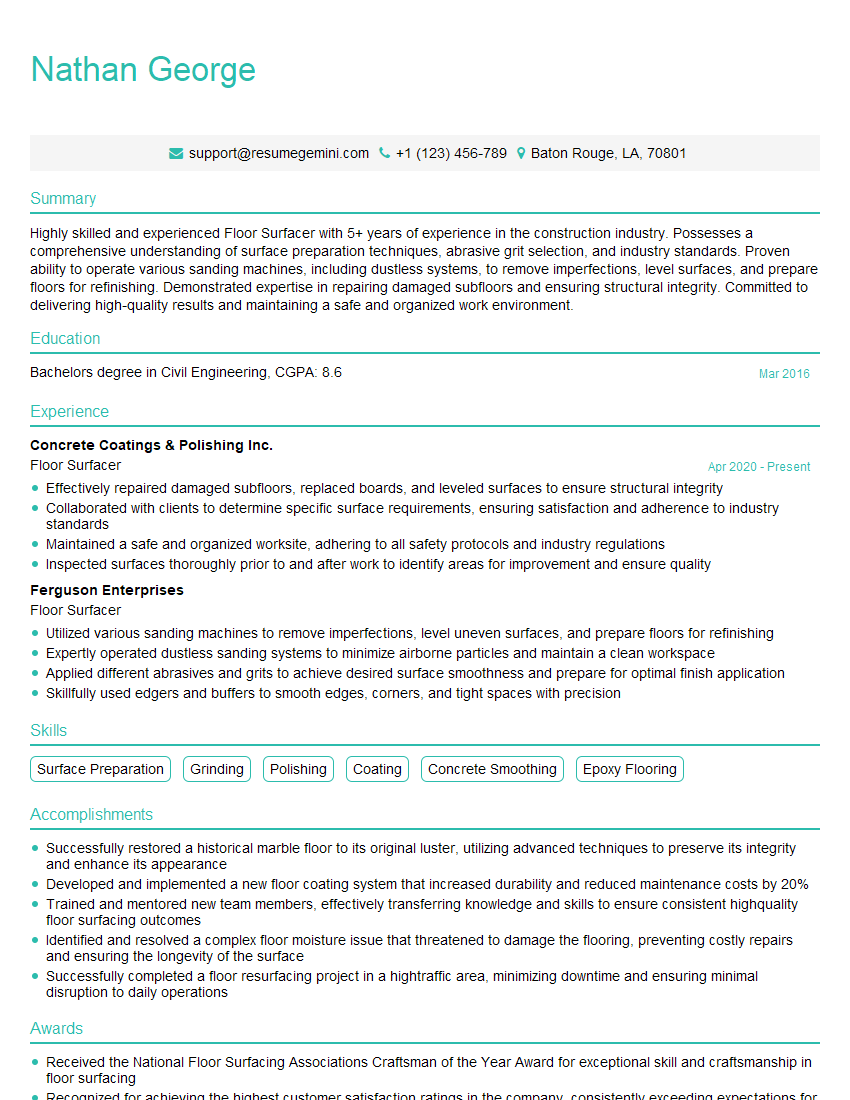

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Floor Surfacer

1. Describe the different types of floor surfacing machines and their uses?

There are several types of floor surfacing machines, each designed for specific tasks:

- Rotary Floor Surfacing Machines: These machines use rotating discs or brushes to clean, polish, and remove coatings from hard floors.

- Orbital Floor Surfacing Machines: Similar to rotary machines, orbital machines use a rotating motion combined with an orbital movement to achieve a smoother finish.

- Edgers: These machines are used to grind and smooth the edges of floors, creating a clean and finished appearance.

- Scarifiers: Heavy-duty machines designed to remove thick coatings, adhesives, and imperfections from concrete and other hard surfaces.

- Polishing Machines: Used to restore and maintain the shine of hard floors, leaving them with a glossy finish.

2. Explain the process of preparing a floor for surface treatment?

Surface Inspection:

- Inspect the floor for any damage, cracks, or imperfections.

- Identify the type of flooring material and its condition.

Floor Cleaning:

- Remove any dirt, debris, or coatings using appropriate cleaning agents.

- Use a stripping solution to dissolve existing finishes or sealers.

Floor Repair:

- Repair any cracks or imperfections using patching materials.

- Level the floor surface if needed using self-leveling compounds.

3. How do you choose the right abrasive for floor surfacing?

The choice of abrasive depends on several factors:

- Floor Material: Abrasives vary in hardness and are matched to the specific floor material (e.g., concrete, hardwood, marble).

- Desired Finish: Different abrasives produce varying levels of smoothness and gloss, depending on the desired finish.

- Floor Condition: Heavily damaged floors may require coarser abrasives to remove imperfections, while well-maintained floors can use finer abrasives for polishing.

- Machine Type: Abrasives should be compatible with the type of floor surfacing machine being used.

4. Describe the steps involved in concrete floor grinding?

- Prepare the floor by removing any coatings or debris.

- Use a grinder with a coarse abrasive to remove the top layer of concrete, exposing the aggregate.

- Switch to finer abrasives to achieve the desired smoothness and remove any imperfections.

- Apply a densifier or sealer to protect the exposed concrete and enhance durability.

5. How do you handle uneven or damaged floors during surfacing?

To handle uneven or damaged floors:

- Inspect the floor: Identify the extent of the damage and unevenness.

- Use a leveling compound: Fill in low spots or level out uneven areas using a self-leveling compound.

- Grind high spots: Use a grinder to remove any high spots or bumps that protrude above the desired level.

- Repair cracks or imperfections: Fill in cracks or repair imperfections with patching materials to create a smooth surface.

6. What safety precautions should be taken when using floor surfacing machines?

- Wear appropriate safety gear (e.g., dust masks, earplugs, safety glasses).

- Ensure the machine is properly grounded and inspected before use.

- Use caution when operating the machine near walls or edges to avoid damage.

- Keep the work area well-ventilated to prevent dust inhalation.

- Avoid contact with moving parts of the machine.

7. How do you maintain and troubleshoot floor surfacing machines?

Maintenance:

- Clean and lubricate the machine regularly as per manufacturer’s instructions.

- Inspect abrasives and replace when worn or damaged.

- Check belts and bearings for proper tension and wear.

Troubleshooting:

- Motor not running: Check power supply, fuses, or circuit breaker.

- Belt slipping: Adjust belt tension or replace if damaged.

- Excessive vibration: Check for loose bolts or worn bearings.

- Uneven grinding: Inspect abrasives for wear or damage.

8. What are the common challenges faced in floor surfacing and how do you overcome them?

- Hard-to-remove coatings: Use appropriate strippers and techniques to dissolve and remove coatings effectively.

- Floor imperfections: Fill in cracks or repair imperfections using appropriate patching materials.

- Dust control: Use dust extractors or wet grinding methods to minimize dust generation.

- Time constraints: Plan the project carefully, allocate sufficient time for each step, and use efficient techniques to meet deadlines.

9. Describe the different types of floor finishes and their characteristics?

- Urethane Coatings: Durable, high-gloss coatings resistant to wear and chemicals.

- Epoxy Coatings: Strong, waterproof coatings that provide excellent chemical resistance.

- Acrylic Coatings: Water-based coatings that are UV-resistant and easy to apply.

- Varnishes: Traditional finishes that provide a protective layer and enhance the natural beauty of wood floors.

- Waxes and Oils: Penetrating finishes that protect and nourish wood floors, enhancing their appearance.

10. What are the latest trends and innovations in floor surfacing technology?

- Autonomous floor surfacing machines: Robotic machines that can operate independently, reducing labor costs.

- Dustless floor grinding systems: Advanced technology that minimizes dust generation during grinding operations.

- Environmentally friendly abrasives: Abrasives made from recycled materials or using sustainable production methods.

- Laser-guided leveling: Systems that use lasers to guide machines for precise floor leveling and grinding.

- Advanced coating application techniques: Innovative methods for applying floor finishes, such as spray-on or self-leveling techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Floor Surfacer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Floor Surfacer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Floor Surfacers are accountable for maintaining the flooring surfaces of an establishment in pristine condition. They employ an array of tools and techniques to clean, polish, and refinish floors, ensuring they are aesthetically pleasing, safe, and hygienic.

1. Cleaning and Maintenance

– Sweep, mop, and vacuum floors regularly to remove dirt, debris, and spills.

– Scrub and polish floors to restore their shine and remove stains.

– Apply protective coatings and sealants to protect floors from damage.

2. Floor Repair

– Repair damaged floors by filling cracks, holes, and gouges.

– Replace damaged floor tiles or planks.

– Refinish floors by sanding them down and applying new coatings.

3. Equipment Operation

– Operate floor cleaning machines, such as buffers, polishers, and scrubbers.

– Use power tools, such as saws, drills, and sanders, for floor repairs.

– Maintain and calibrate floor care equipment to ensure optimal performance.

4. Safety and Compliance

– Follow safety protocols when handling chemicals and operating equipment.

– Adhere to environmental regulations regarding the disposal of cleaning products.

– Report any potential hazards or safety concerns to supervisors.

Interview Tips

To ace an interview for a Floor Surfacer position, candidates should prepare diligently and showcase their skills and experience.

1. Research the Company and Industry

– Familiarize yourself with the company’s history, culture, and values.

– Understand the specific industry in which the company operates.

2. Highlight Relevant Skills

– Emphasize your proficiency in floor cleaning, repair, and refinishing techniques.

– Showcase your knowledge of floor care equipment and safety procedures.

3. Demonstrate a Strong Work Ethic

– Convey your commitment to hard work, attention to detail, and a clean work environment.

– Share examples of when you went above and beyond to ensure floor surfaces were impeccably maintained.

4. Prepare for Common Interview Questions

– Practice answering typical interview questions, such as “Tell me about your experience in floor surfacing” and “Why are you interested in this role?”.

– Prepare specific examples to illustrate your skills and abilities.

5. Dress Professionally and Arrive on Time

– First impressions matter, so dress appropriately for the interview.

– Punctuality demonstrates respect for the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Floor Surfacer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!