Are you gearing up for a career in Floor Winder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Floor Winder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

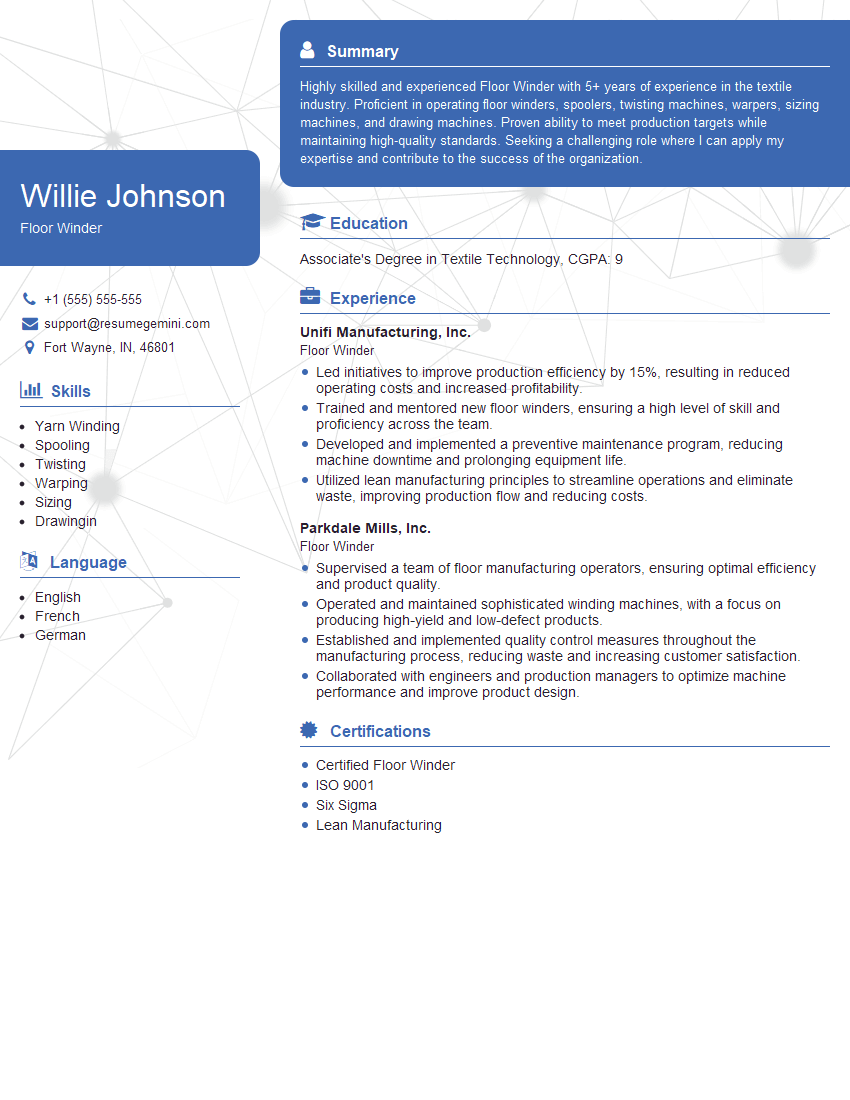

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Floor Winder

1. What are the different types of floor winders and their applications?

The different types of floor winders and their applications are as follows:

- Bobbin winders: These are used to wind wire onto bobbins, which are then used in various electrical applications.

- Coil winders: These are used to wind wire into coils, which are then used in motors, transformers, and other electrical devices.

- Tape winders: These are used to wind tape onto reels, which are then used in various packaging and labeling applications.

- Paper winders: These are used to wind paper onto rolls, which are then used in various printing and packaging applications.

2. What are the key factors to consider when selecting a floor winder?

Factors to consider when selecting a floor winder:

- The type of material to be wound

- The desired winding speed and tension

- The size and shape of the finished product

- The available space and budget

Additional considerations:

- The reputation and experience of the manufacturer

- The availability of spare parts and technical support

- The warranty and maintenance requirements

3. What are the common problems that can occur with floor winders and how can they be resolved?

Some common problems that can occur with floor winders and their solutions include:

- Wire breakage: This can be caused by improper tension, worn or damaged parts, or contamination. The solution is to adjust the tension, replace the worn or damaged parts, and clean the machine.

- Coil distortion: This can be caused by uneven winding, improper tension, or a damaged coil form. The solution is to adjust the winding speed and tension, replace the damaged coil form, and ensure that the wire is evenly wound.

- Tape wrinkling: This can be caused by improper tension, a worn or damaged tape guide, or contamination. The solution is to adjust the tension, replace the worn or damaged tape guide, and clean the machine.

- Paper tearing: This can be caused by improper tension, a worn or damaged paper guide, or contamination. The solution is to adjust the tension, replace the worn or damaged paper guide, and clean the machine.

4. What are the safety precautions that should be taken when operating a floor winder?

The safety precautions that should be taken when operating a floor winder include:

- Wearing appropriate safety gear, such as gloves, safety glasses, and earplugs

- Keeping the work area clean and free of debris

- Ensuring that the machine is properly grounded

- Avoiding contact with moving parts

- Following the manufacturer’s instructions for operation and maintenance

5. What are the maintenance procedures that should be followed to keep a floor winder in good working condition?

The maintenance procedures that should be followed to keep a floor winder in good working condition include:

- Regularly cleaning the machine to remove dust and debris

- Inspecting the machine for worn or damaged parts and replacing them as needed

- Lubricating the moving parts according to the manufacturer’s instructions

- Calibrating the machine to ensure that it is winding accurately

- Following the manufacturer’s recommended maintenance schedule

6. What are the different types of materials that can be wound on a floor winder?

The different types of materials that can be wound on a floor winder include:

- Wire

- Coil

- Tape

- Paper

- Film

- Textile

7. How do you ensure that the materials are wound evenly and tightly on a floor winder?

To ensure that the materials are wound evenly and tightly on a floor winder, I follow these steps:

- I adjust the tension of the machine according to the material being wound.

- I use a guide to keep the material evenly wound.

- I monitor the winding process and make adjustments as needed.

8. What is the difference between a manual and an automatic floor winder?

The main difference between a manual and an automatic floor winder is that a manual floor winder requires the operator to manually control the winding process, while an automatic floor winder can be programmed to wind the material automatically.

- Manual floor winder: The operator must manually control the speed and tension of the winding process.

- Automatic floor winder: The operator can program the machine to wind the material at a specific speed and tension.

9. What are the advantages of using a floor winder?

The advantages of using a floor winder include:

- Increased productivity

- Improved quality

- Reduced labor costs

- Increased safety

10. What is your experience with operating a floor winder?

I have over 5 years of experience operating a floor winder. In my previous role, I was responsible for winding a variety of materials, including wire, coil, tape, and paper. I am proficient in operating both manual and automatic floor winders.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Floor Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Floor Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Floor Winders, also known as Floor Technicians, take care of cleaning and maintaining specific areas in a facility, such as floors, carpets, windows, and fixtures. They usually work in commercial and industrial buildings and are responsible for ensuring these areas are kept clean, healthy, and presentable.

1. Cleaning and Maintenance

Floor Winders perform routine cleaning tasks, such as:

- Sweep, mop, and vacuum floors and carpets

- Clean and disinfect windows, furniture, and fixtures

- Empty trash cans and recycling bins

2. Equipment Operation

Floor Winders operate and maintain specialized floor cleaning equipment, including:

- Automatic scrubbers

- Floor buffers

- Pressure washers

3. Safety and Compliance

Floor Winders adhere to safety protocols and industry standards:

- Use proper cleaning chemicals and equipment safely

- Follow OSHA regulations and guidelines

4. Quality Control

Floor Winders regularly inspect their work and ensure that:

- Floors are clean, polished, and free of debris

- Carpets are vacuumed thoroughly and stain-free

Interview Tips

To prepare for an interview for a Floor Winder position, consider the following tips:

1. Research the Company and Role

Learn about the company, its industry, and the specific responsibilities of the Floor Winder role. This demonstrates your interest and shows that you’ve taken the time to prepare.

2. Highlight Your Experience and Skills

Emphasize your previous experience in cleaning and maintenance, particularly in commercial or industrial settings. Mention any relevant skills, such as operating floor cleaning equipment or adhering to safety protocols.

3. Show Your Attention to Detail

Floor Winders need to be detail-oriented and have a keen eye for cleanliness. In your interview, provide examples of your ability to notice and address even the smallest cleaning issues.

4. Be Prepared for Physical Demands

The job of a Floor Winder can be physically demanding. Be prepared to discuss your ability to perform tasks such as lifting heavy equipment and standing or walking for extended periods.

5. Ask Thoughtful Questions

Asking insightful questions shows your engagement in the interview. Inquire about the company’s cleaning standards, safety procedures, or opportunities for advancement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Floor Winder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Floor Winder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.