Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flotation Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flotation Operator so you can tailor your answers to impress potential employers.

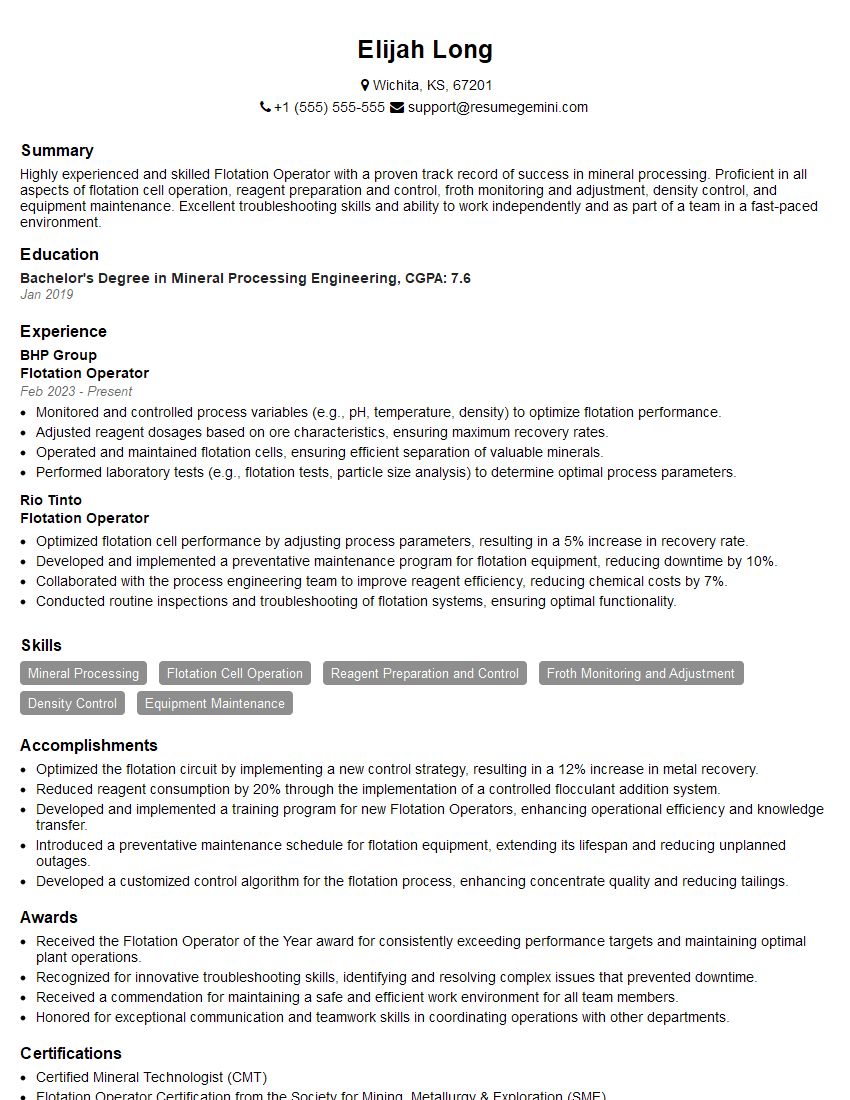

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flotation Operator

1. What are the different types of flotation cells?

There are various types of flotation cells, including mechanical, pneumatic, and column cells. Each type has its own advantages and is used for different applications. For instance, mechanical cells excel in handling coarse particles, while column cells are efficient for fine particle recovery.

2. Explain the role of frothers and collectors in the flotation process.

Role of Frothers

- Reduce surface tension of water, promoting bubble formation.

- Stabilize bubbles, preventing their coalescence.

- Aid in particle attachment to bubbles.

Role of Collectors

- Make mineral particles hydrophobic, promoting their attachment to air bubbles.

- Selective in their action, binding to specific minerals.

- Enhance mineral recovery while reducing gangue contamination.

3. How do you optimize flotation performance?

Optimizing flotation performance involves several key factors, including:

- Particle size and liberation

- Pulp chemistry (pH, redox potential)

- Flotation cell type and operating conditions

- Collector and frother selection and dosage

- Monitoring and control of process parameters

4. Describe the process of flotation column troubleshooting.

Troubleshooting flotation columns involves a systematic approach to identify and rectify issues affecting performance. It includes:

- Assessing feed characteristics and operating conditions

- Inspecting equipment for mechanical problems

- Analyzing froth quality and recovery rates

- Adjusting process parameters (e.g., air flow, feed rate)

- Investigating potential reagent issues

5. How do you ensure the safety of flotation operations?

Ensuring safety in flotation operations is crucial and involves adhering to strict protocols:

- Proper handling and storage of chemicals

- Regular maintenance and inspection of equipment

- Use of personal protective equipment (PPE)

- Training and supervision of personnel

- Emergency response planning and procedures

6. What are the key performance indicators (KPIs) for flotation operations?

KPIs for flotation operations include:

- Recovery rate: Percentage of valuable minerals recovered

- Grade: Concentration of valuable minerals in the concentrate

- Tailings loss: Percentage of valuable minerals lost in the tailings

- Throughput: Volume of material processed per unit time

- Reagent consumption: Amount of reagents used per unit of ore

7. How do you handle variations in ore characteristics?

Variations in ore characteristics require adjustments to the flotation process. Strategies include:

- Modifying collector and frother dosages

- Adjusting pH and redox potential

- Investigating alternative reagents

- Optimizing operating conditions (e.g., impeller speed, air flow)

- Implementing staged flotation or selective flotation techniques

8. What is the impact of particle size on flotation recovery?

Particle size significantly affects flotation recovery. Smaller particles:

- Have a larger surface area for reagent interaction

- Are more readily entrained in air bubbles

- Exhibit higher recovery rates

- However, excessive grinding can lead to over-sliming and reduced recovery

9. How do you optimize froth depth in a flotation cell?

Optimizing froth depth is essential for efficient flotation. Considerations include:

- Froth depth should be sufficient to allow for bubble-particle attachment

- Excessive froth depth can hinder bubble-particle collisions

- Froth depth can be adjusted by modifying air flow rate and impeller speed

- Monitoring froth stability and quality is crucial for optimization

10. What are the potential environmental concerns associated with flotation operations?

Environmental concerns related to flotation operations include:

- Tailings disposal and management

- Chemical usage and potential toxicity

- Noise and dust generation

- Minimizing environmental impact requires responsible waste management, proper reagent selection, and adherence to environmental regulations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flotation Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flotation Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flotation Operators are responsible for the operation and maintenance of flotation machines, which are used to separate minerals from waste materials. Key responsibilities of a Flotation Operator include:

1. Operating flotation machines

Flotation Operators are responsible for operating flotation machines, which use air bubbles to separate minerals from waste materials. They must be able to adjust the operating parameters of the machines to achieve the desired results.

2. Monitoring flotation process

Flotation Operators must monitor the flotation process to ensure that it is running smoothly and efficiently. They must be able to identify and correct any problems that may occur.

3. Maintaining flotation machines

Flotation Operators are responsible for maintaining flotation machines. They must be able to perform routine maintenance tasks, such as cleaning, lubricating, and adjusting the machines.

4. Troubleshooting flotation problems

Flotation Operators must be able to troubleshoot flotation problems. They must be able to identify the cause of the problem and take steps to correct it.

Interview Tips

To ace the interview for a Flotation Operator position, it is important to be prepared. Here are some tips:

1. Research the company and the position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” It is helpful to practice answering these questions in advance.

3. Be prepared to talk about your experience

The interviewer will likely want to know about your experience in the field. Be prepared to talk about your previous experience operating and maintaining flotation machines.

4. Be prepared to talk about your skills

The interviewer will also want to know about your skills. Be prepared to talk about your skills in operating and maintaining flotation machines, as well as your troubleshooting skills.

5. Be prepared to talk about your goals

The interviewer may also want to know about your goals. Be prepared to talk about your career goals and how this position fits into those goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flotation Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!