Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flotation Tender Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flotation Tender Helper so you can tailor your answers to impress potential employers.

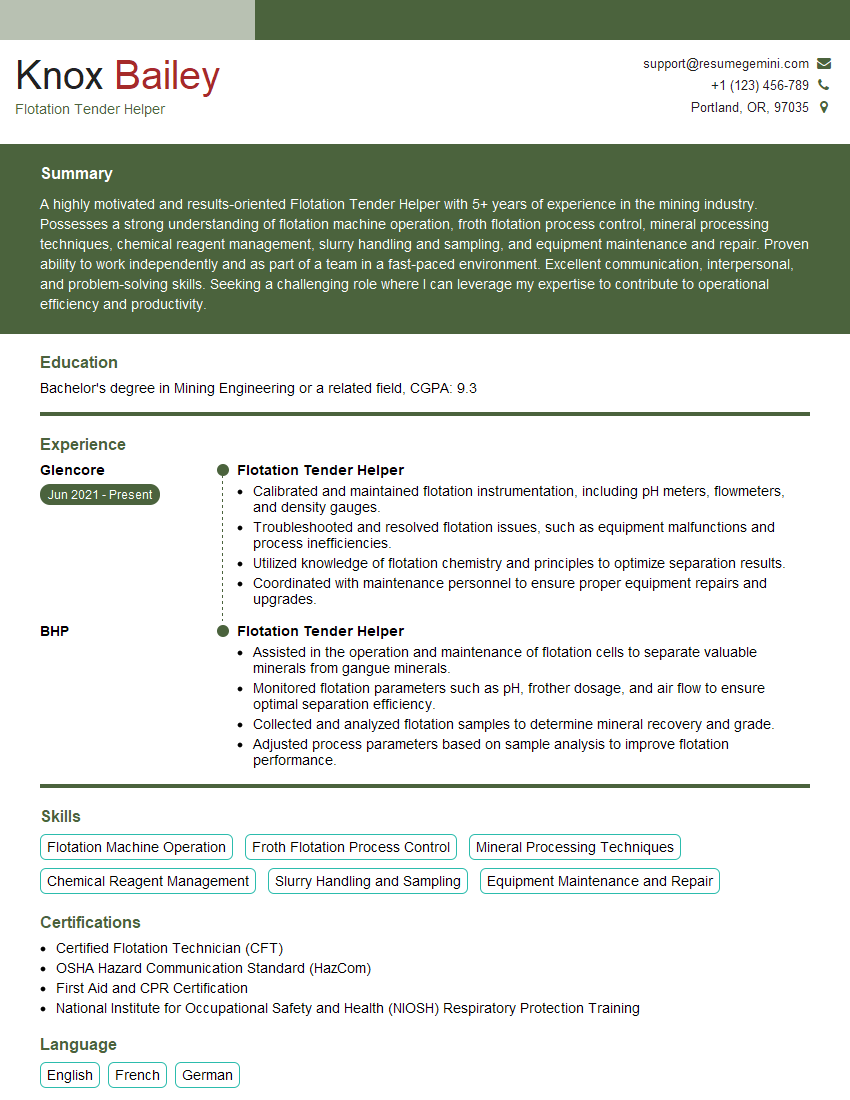

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flotation Tender Helper

1. Explain the key responsibilities and duties of a Flotation Tender Helper?

As a Flotation Tender Helper, I would be responsible for assisting with the operation and maintenance of flotation equipment.

- Assist with the installation, operation, and maintenance of flotation equipment

- Monitor the operation of flotation equipment and make necessary adjustments

- Help to maintain a clean and safe work area

- Perform other duties as assigned by supervisor

2. How do you ensure the proper operation of flotation machines to achieve optimal separation results?

Monitoring Flotation Equipment

- Regularly monitoring flotation machine performance parameters (e.g., feed rate, air flow, froth depth)

- Identifying any deviations from optimal operating ranges

- Making timely adjustments to ensure efficient separation

Process Control Adjustments

- Adjusting reagent dosage to optimize mineral recovery and selectivity

- Modifying flotation cell operating conditions (e.g., impeller speed, air flow) to improve separation performance

- Collaborating with plant operators to optimize overall processing efficiency

3. Describe the principles of flotation and how they are applied in the mining industry?

Flotation is a process used to separate minerals from gangue (waste) by selectively attaching air bubbles to the desired minerals.

- The process involves mixing ground ore with water, reagents, and air in a flotation cell.

- Air bubbles attach to hydrophobic (water-repelling) mineral particles, forming a froth that floats to the surface.

- The froth is skimmed off, while the hydrophilic (water-loving) gangue particles remain in the water.

4. How do you troubleshoot common problems associated with flotation machines?

Common problems with flotation machines and their troubleshooting steps:

- Low recovery: Check feed rate, air flow, reagent dosage, and impeller speed. Optimize process parameters and adjust settings accordingly.

- High froth volume: Reduce air flow, adjust impeller speed, or add anti-foaming agent to control froth levels.

- Poor selectivity: Optimize reagent dosage and adjust flotation pH to improve selectivity between desired minerals and gangue.

- Mechanical issues: Inspect and maintain equipment regularly for worn or damaged parts. Replace or repair components as needed.

5. Explain the importance of maintaining a clean and safe work area in a flotation plant?

- Safety: To prevent slips, trips, and falls, as well as exposure to hazardous chemicals and dust.

- Equipment maintenance: To ensure efficient operation of flotation machines and minimize breakdowns.

- Product quality: To prevent contamination of flotation products and maintain desired mineral grades.

- Environmental compliance: To minimize the release of harmful substances into the environment.

6. Describe your experience in working with reagents used in flotation processes?

In my previous role, I was responsible for handling and preparing flotation reagents.

- Familiar with different types of reagents (collectors, frothers, modifiers)

- Experienced in calculating reagent dosages based on ore characteristics and process conditions

- Monitored reagent consumption and adjusted dosages as needed to optimize separation results

7. How do you handle and store flotation reagents safely and effectively?

- Follow established safety protocols and wear appropriate personal protective equipment (PPE)

- Store reagents in designated, well-ventilated areas to prevent spills and leaks

- Monitor reagent levels and maintain proper inventory to avoid shortages or overstocking

- Dispose of expired or unused reagents according to environmental regulations

8. Explain the importance of preventive maintenance for flotation equipment?

- Increased uptime: Regular maintenance helps identify and address potential problems early on, reducing unplanned downtime.

- Improved efficiency: Well-maintained equipment operates more efficiently, leading to higher productivity and lower operating costs.

- Extended equipment life: Preventive maintenance helps extend the lifespan of flotation machines by reducing wear and tear.

- Safety: Regularly inspecting and servicing equipment minimizes the risk of accidents and ensures a safe work environment.

9. Describe your experience in working with other team members in a flotation plant?

In my previous role, I worked closely with other team members to ensure smooth operation of the flotation plant.

- Communicated regularly with operators, supervisors, and maintenance personnel

- Assisted with equipment troubleshooting and process optimization

- Contributed to team efforts to improve safety and efficiency

10. Why are you interested in working as a Flotation Tender Helper in our company?

- I am excited about the opportunity to contribute my skills and experience to your reputable company.

- I am eager to learn from experienced professionals and contribute to the success of your flotation operations.

- I am particularly interested in the company’s commitment to safety, innovation, and environmental sustainability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flotation Tender Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flotation Tender Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Flotation Tender Helper is responsible for assisting in the operation of a flotation process, which involves separating valuable minerals from waste materials using a froth flotation technique. Key responsibilities include:1. Process Operation

- Monitoring and adjusting process parameters to optimize recovery and grade

- Operating and maintaining flotation cells, pumps, and other equipment

- Collecting and analyzing samples to ensure process efficiency

2. Equipment Maintenance

- Performing regular inspections and preventative maintenance on flotation equipment

- Troubleshooting and resolving mechanical and electrical issues

- Assisting in major repairs and overhauls

3. Health and Safety

- Following all safety protocols and procedures

- Wearing appropriate personal protective equipment (PPE)

- Maintaining a clean and organized work area

4. Teamwork and Communication

- Collaborating with other team members to ensure smooth operation

- Communicating effectively with supervisors and other stakeholders

- Participating in training and development programs

Interview Tips

To ace an interview for a Flotation Tender Helper position, candidates should follow these tips:1. Research the Company and Industry

- Learn about the company’s background, products, and operations

- Understand the key trends and challenges in the mining and minerals processing industry

- Identify the specific responsibilities and requirements of the role

2. Highlight Relevant Experience and Skills

- Emphasize any prior experience in flotation operations or related fields

- Showcase your mechanical and electrical troubleshooting skills

- Demonstrate your commitment to safety and attention to detail

3. Prepare for Common Interview Questions

- Tell me about your experience in flotation operations

- Describe your approach to troubleshooting mechanical and electrical issues

- How do you ensure that you follow all safety protocols?

4. Ask Meaningful Questions

- Inquire about the company’s future plans and growth prospects

- Ask about the training and development opportunities available

- Seek insights into the company’s culture and values

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Flotation Tender Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.