Are you gearing up for a career in Flour Tester? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Flour Tester and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

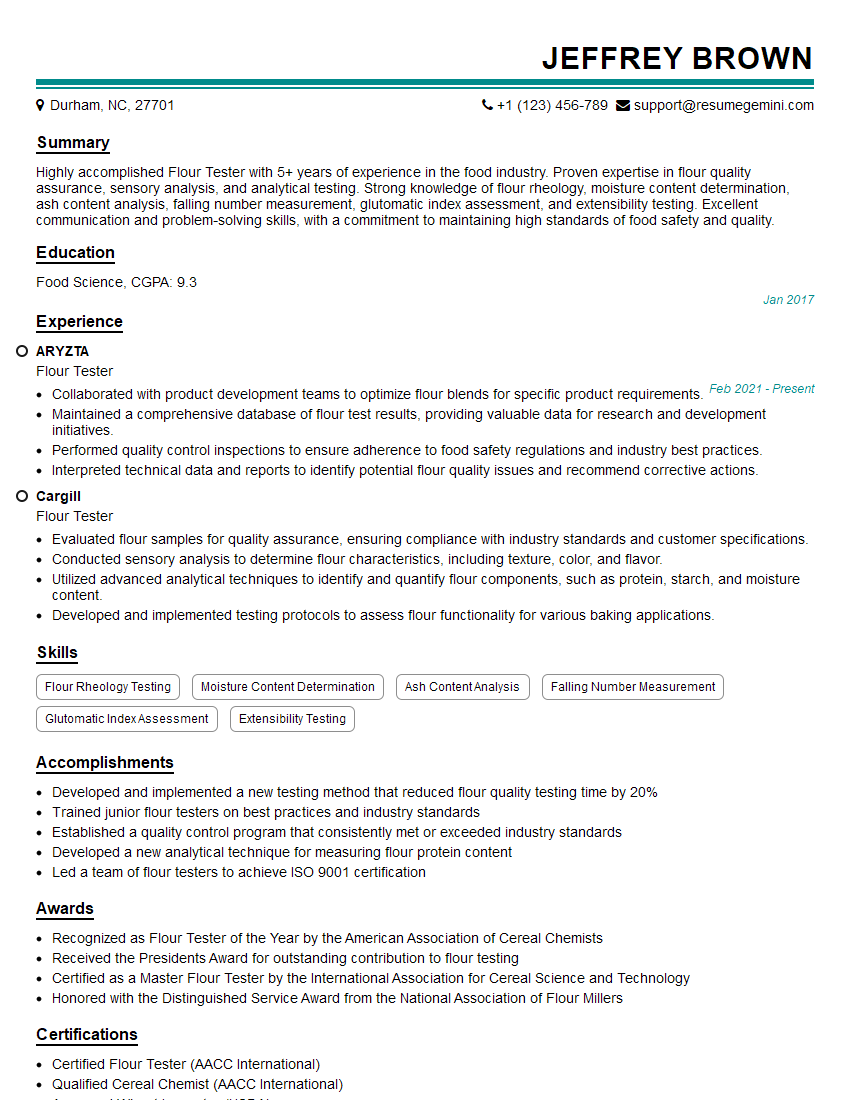

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flour Tester

1. What are the key factors that influence the quality of flour?

The key factors that influence the quality of flour include:

- Wheat variety: Different wheat varieties have different genetic characteristics that affect the quality of the flour, such as protein content, gluten strength, and water absorption.

- Growing conditions: Environmental factors such as soil type, climate, and irrigation practices can affect the wheat’s protein content and gluten strength.

- Milling process: The way the wheat is milled, including the type of mill and the grind size, can impact the flour’s texture, color, and ash content.

2. Describe the different methods used to test flour quality.

Different methods used to test flour quality include:

Chemical tests:

- Moisture content

- Protein content

- Ash content

Physical tests:

- Falling number

- farinograph

- extensograph

Sensory tests:

- Color

- Texture

- Taste

3. How do you interpret the results of flour quality tests?

The results of flour quality tests are interpreted to determine the suitability of the flour for different applications. For example:

- Protein content: High protein flour is suitable for bread-making, while low protein flour is better for pastries and cakes.

- Gluten strength: Strong gluten flour is ideal for bread, while weak gluten flour is preferred for cookies and crackers.

- Water absorption: Flour with high water absorption will produce a dough with a higher yield, while flour with low water absorption will produce a dough that is drier and less extensible.

4. What are the common defects in flour?

Common defects in flour include:

- Insect infestation: Flour can become infested with insects, which can damage the flour and make it unsuitable for human consumption.

- Mold: Flour can develop mold if it is stored in a humid environment.

- Rancidity: Flour can become rancid if it is exposed to heat or light.

- Bleaching: Flour can be bleached to improve its color, but this can also damage the flour’s nutritional value.

5. How do you control the quality of flour in a flour mill?

To control the quality of flour in a flour mill, several steps are taken:

- Wheat selection: The mill selects high-quality wheat varieties that are suitable for the intended flour products.

- Cleaning and conditioning: The wheat is cleaned to remove impurities and then conditioned to adjust the moisture content, which improves milling efficiency.

- Milling: The wheat is milled using a series of rollers to break down the wheat kernels and separate the flour from the bran and shorts.

- Quality control: The flour is tested throughout the milling process to ensure that it meets the desired specifications.

6. What are the latest trends in flour testing?

Latest trends in flour testing include:

- Near-infrared (NIR) spectroscopy: NIR spectroscopy is a rapid and non-destructive method for measuring flour quality parameters, such as protein content and gluten strength.

- Automated image analysis: Automated image analysis systems can be used to assess the physical characteristics of flour, such as particle size and shape.

- Molecular markers: Molecular markers are being developed to identify specific genes that are associated with desired flour quality traits.

7. What is the role of a flour tester in a food manufacturing company?

In a food manufacturing company, the role of a flour tester is to:

- Ensure the quality of incoming flour: The flour tester tests incoming flour shipments to ensure that they meet the company’s specifications.

- Monitor flour quality during production: The flour tester monitors flour quality throughout the production process to ensure that the flour is performing as expected.

- Troubleshoot flour-related problems: The flour tester troubleshoots any flour-related problems that may arise during production.

- Develop new flour products: The flour tester may also be involved in developing new flour products.

8. What are the qualifications and experience required to be a flour tester?

Qualifications and experience required to be a flour tester typically include:

- Bachelor’s degree in food science or a related field: A bachelor’s degree in food science or a related field is typically required.

- Experience in flour testing: Experience in flour testing, either in a flour mill or a food manufacturing company, is highly desirable.

- Strong analytical skills: Strong analytical skills are essential for interpreting flour test results.

- Excellent communication skills: Excellent communication skills are necessary for communicating test results and recommendations to other departments.

9. What are the challenges of being a flour tester?

Some of the challenges of being a flour tester include:

- Keeping up with the latest trends in flour testing: The field of flour testing is constantly evolving, so it is important to stay up-to-date on the latest trends.

- Dealing with a variety of flours: Flour testers must be able to test a wide variety of flours, each with its own unique characteristics.

- Interpreting test results: Interpreting flour test results can be complex, and it requires a deep understanding of flour science.

- Working under pressure: Flour testers often work under pressure, as they are responsible for ensuring the quality of flour used in food products.

10. What is the most rewarding part of being a flour tester?

The most rewarding part of being a flour tester is:

- Ensuring the quality of food products: Flour is a key ingredient in many food products, and flour testers play a vital role in ensuring the quality of these products.

- Solving problems: Flour testers are often called upon to solve problems related to flour quality. Solving these problems can be challenging, but it is also very rewarding.

- Learning new things: The field of flour testing is constantly evolving, and there is always something new to learn.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flour Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flour Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flour Testers play a crucial role in the food industry. They are responsible for ensuring the quality of flour by conducting various tests.

1. Flour Testing and Analysis

Flour Testers conduct a series of tests to evaluate the quality of flour, including:

- Moisture content testing

- Protein content analysis

- Ash content determination

- Falling number test

2. Quality Control

Flour Testers ensure that the flour meets the specified quality standards. They compare the test results against established criteria and identify any deviations.

- Developing and implementing quality control measures

- Monitoring production processes to ensure consistent quality

3. Research and Development

Flour Testers participate in research and development activities to improve flour quality. They explore new methods and technologies for flour testing and analysis.

- Investigating new flour varieties

- Developing innovative testing techniques

4. Technical Documentation and Reporting

Flour Testers document their findings, prepare reports, and provide technical support to other departments. They communicate their results effectively to stakeholders.

- Maintaining accurate records of test results

- Providing technical guidance to flour users

Interview Tips

To ace the interview for a Flour Tester position, it is essential to prepare thoroughly.

1. Research the Role and Company

Familiarize yourself with the job description and the company’s website. Understand the company’s mission, values, and the role’s specific responsibilities.

- Example: “I have carefully reviewed the job description and I am particularly interested in your company’s commitment to sustainability and innovation in flour production.”

2. Highlight Relevant Experience and Skills

Emphasize your technical skills and laboratory experience in flour testing or related fields. Quantify your accomplishments and provide specific examples of your work.

- Example: “In my previous role, I was responsible for conducting a wide range of flour tests, including moisture content, protein content, and ash content analysis. I developed and implemented a new method for determining flour quality that resulted in a 15% increase in efficiency.”

3. Demonstrate Knowledge of Industry Standards

Show your understanding of industry standards and best practices for flour testing. Discuss your familiarity with relevant testing methods and quality control measures.

- Example: “I am well-versed in industry standards such as AACC and ICC methods. I have also participated in proficiency testing programs to ensure the accuracy and precision of my work.”

4. Prepare for Technical Questions

Expect to answer technical questions related to flour testing. Be prepared to discuss your knowledge of flour chemistry, testing equipment, and data analysis methods.

- Example: “I have a strong understanding of flour chemistry, particularly the role of proteins and starch in flour quality. I am also proficient in using various testing equipment, such as moisture meters, protein analyzers, and falling number testers.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flour Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!