Are you gearing up for a career in Flower Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Flower Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

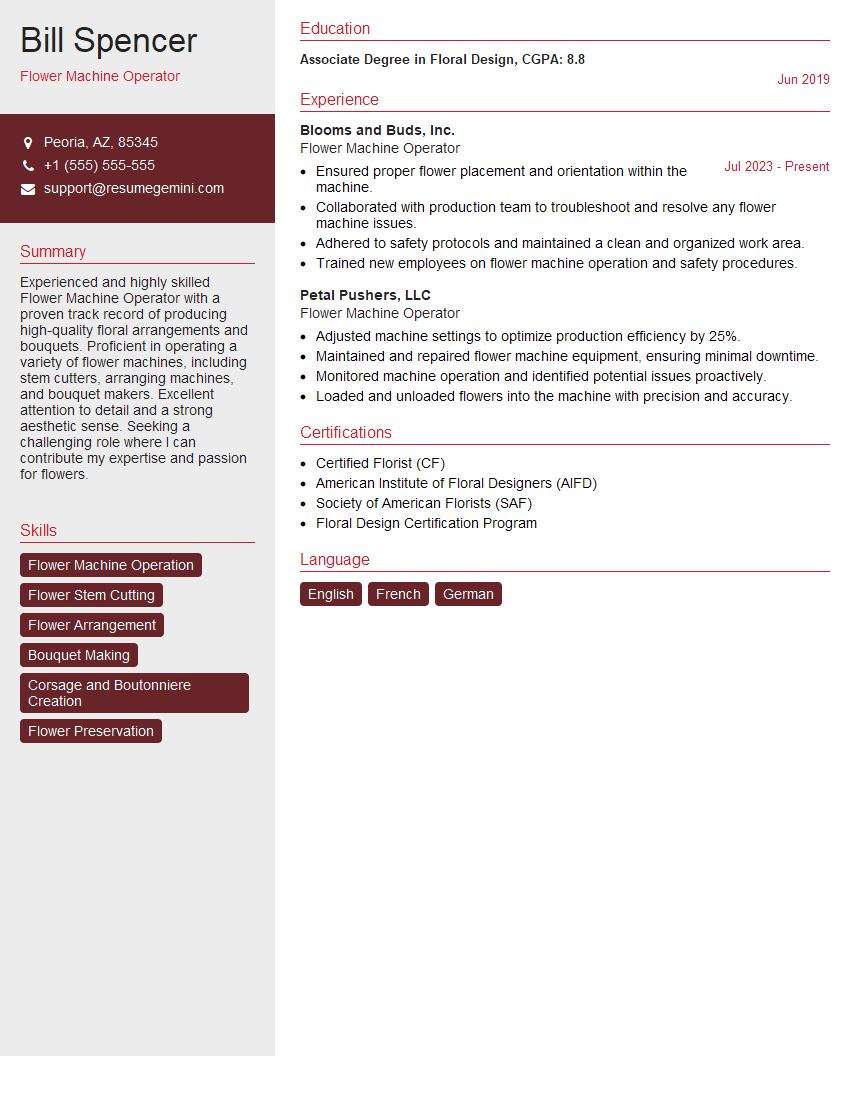

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flower Machine Operator

1. What is the process of operating a flower machine?

The process of operating a flower machine involves several key steps:

- Loading flowers into the machine’s hopper or conveyor belt

- Setting the machine’s parameters, such as cutting length and speed

- Monitoring the machine’s operation to ensure it is processing flowers correctly

- Removing processed flowers from the machine’s output conveyor belt

- Cleaning and maintaining the machine according to manufacturer’s guidelines

2. What types of flowers can be processed using a flower machine?

Flower machines are designed to process a wide variety of flowers, including:

- Roses

- Carnations

- Lilies

- Chrysanthemums

- Gerbera daisies

The type of flower that can be processed will depend on the specific machine’s capabilities and blade design.

3. How do you ensure that the flowers processed by the machine meet the required quality standards?

To ensure the quality of processed flowers, I follow these steps:

- Inspecting flowers before loading them into the machine to remove any damaged or blemished flowers

- Calibrating the machine regularly to maintain accurate cutting lengths

- Monitoring the machine’s operation to detect any deviations from the desired settings

- Performing regular cleaning and maintenance to keep the machine in good working condition

4. What safety precautions should be taken when operating a flower machine?

When operating a flower machine, I prioritize safety by adhering to these precautions:

- Wearing appropriate safety gear, including gloves, safety glasses, and a hairnet

- Keeping the work area clean and free of tripping hazards

- Ensuring that the machine is properly grounded and electrically safe

- Keeping hands and other body parts away from moving parts of the machine

- Following all manufacturer’s safety instructions and guidelines

5. How do you troubleshoot common problems that may occur when operating a flower machine?

When troubleshooting common flower machine problems, I follow a systematic approach:

- Identifying the problem, such as uneven cuts or flower damage

- Checking the machine’s settings and making necessary adjustments

- Inspecting the machine for any blockages or damaged parts

- Consulting the manufacturer’s manual or seeking guidance from a qualified technician

- Taking appropriate corrective actions, such as cleaning the machine, replacing worn parts, or recalibrating the settings

6. What maintenance tasks are required to keep a flower machine in good working condition?

To maintain optimal performance and prevent breakdowns, I perform the following maintenance tasks:

- Cleaning the machine regularly, including the cutting blades, conveyor belts, and electrical components

- Lubricating moving parts according to the manufacturer’s instructions

- Inspecting the machine for any signs of wear or damage, and replacing or repairing parts as needed

- Performing regular calibration to ensure accurate cutting lengths

- Following the manufacturer’s recommended maintenance schedule

7. How do you ensure that the flowers processed by the machine are handled with care to minimize damage?

To minimize flower damage during processing, I take the following precautions:

- Handling flowers gently when loading and unloading them from the machine

- Using sharp, well-maintained cutting blades to ensure clean cuts

- Setting the machine’s parameters to minimize vibration and stress on the flowers

- Avoiding overfeeding the machine to prevent overcrowding and flower damage

- Storing processed flowers in a cool, humid environment to maintain their freshness

8. How do you optimize the efficiency of the flower machine to increase productivity?

To enhance the efficiency of the flower machine and maximize productivity, I implement these strategies:

- Loading the machine with the optimal amount of flowers to avoid overloading or underfeeding

- Fine-tuning the machine’s settings to achieve the desired cutting length and speed

- Keeping the machine well-maintained to minimize downtime and ensure smooth operation

- Streamlining the workflow to reduce bottlenecks and improve overall efficiency

9. How do you stay updated on the latest advancements in flower machine technology?

To keep abreast of the latest advancements in flower machine technology, I engage in the following activities:

- Attending industry workshops and conferences

- Reading trade publications and technical journals

- Consulting with equipment manufacturers and suppliers

- Exploring online resources and forums dedicated to flower machine technology

- Seeking opportunities for training and professional development

10. How do you handle situations where the flower machine breaks down or malfunctions?

When encountering a flower machine breakdown or malfunction, I take the following steps:

- Immediately stopping the machine to prevent further damage

- Identifying the potential cause of the problem based on my knowledge and experience

- Consulting the manufacturer’s manual or seeking guidance from a qualified technician

- Taking appropriate corrective actions, such as replacing fuses, tightening loose connections, or cleaning sensors

- Reporting the issue to my supervisor and initiating the necessary repair or maintenance procedures

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flower Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flower Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flower Machine Operators are responsible for the day-to-day operation and maintenance of flower machines. They work in a fast-paced environment, ensuring that flowers are processed, packaged, and shipped on time.

1. Operate Flower Machines

The primary responsibility of a Flower Machine Operator is to operate flower machines. This includes setting up the machine, loading the flowers, and monitoring the process.

- Set up and calibrate flower machines according to specifications.

- Load flowers into the machine and adjust settings to ensure optimal processing.

- Monitor the operation of the machine and make adjustments as needed to maintain quality and efficiency.

2. Inspect and Maintain Equipment

Flower Machine Operators are also responsible for inspecting and maintaining equipment. This includes cleaning, lubricating, and repairing machines to ensure they are in good working order.

- Clean and lubricate flower machines and equipment regularly to prevent breakdowns.

- Inspect machines for wear and tear, and perform minor repairs as necessary.

- Identify potential problems and report them to supervisors for timely resolution.

3. Handle and Process Flowers

Flower Machine Operators may also be responsible for handling and processing flowers. This includes sorting, grading, and packing flowers to ensure they meet quality standards.

- Sort and grade flowers based on size, color, and quality.

- Pack flowers into boxes or crates for storage or shipment.

- Maintain a clean and organized work area to prevent contamination or damage to flowers.

4. Keep Records and Maintain Inventory

Flower Machine Operators may also be responsible for keeping records and maintaining inventory. This includes tracking the number of flowers processed, the quality of the flowers, and the inventory of supplies.

- Maintain accurate records of flower processing and quality control.

- Track inventory of flowers and supplies to ensure adequate stock levels.

- Report any discrepancies or shortages to supervisors for timely action.

Interview Tips

To ace the interview for a Flower Machine Operator position, it is important to prepare adequately. Here are some tips and hacks to help you succeed:

1. Research the Company and Position

Before the interview, take the time to research the company you are applying to and the specific Flower Machine Operator position. This will help you understand the company’s culture, values, and expectations for the role.

- Visit the company’s website to learn about their history, mission, and products/services.

- Read online reviews and testimonials to gain insights into the company’s reputation and employee experience.

- Review the job description carefully to identify the key responsibilities, skills, and qualifications required for the position.

2. Highlight Relevant Skills and Experience

In your resume and interview answers, emphasize the skills and experience that are most relevant to the Flower Machine Operator role. This may include your ability to operate flower machines, inspect and maintain equipment, handle and process flowers, and keep records.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Use keywords from the job description in your resume and interview responses to show the interviewer that you have the necessary qualifications.

- Be prepared to discuss specific examples of your work experience that demonstrate your skills and abilities.

3. Prepare for Common Interview Questions

Research common interview questions for Flower Machine Operator positions and prepare your answers in advance. This will help you feel more confident and prepared during the interview.

- Practice answering questions about your experience operating flower machines, handling and processing flowers, and maintaining equipment.

- Be prepared to discuss your knowledge of flower quality standards and safety regulations.

- Consider questions about your teamwork, problem-solving skills, and attention to detail.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. This shows the interviewer that you respect the position and the company.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Arrive on time for your interview to demonstrate your punctuality and respect for the interviewer’s time.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flower Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!