Are you gearing up for an interview for a Flower Pot Press Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Flower Pot Press Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

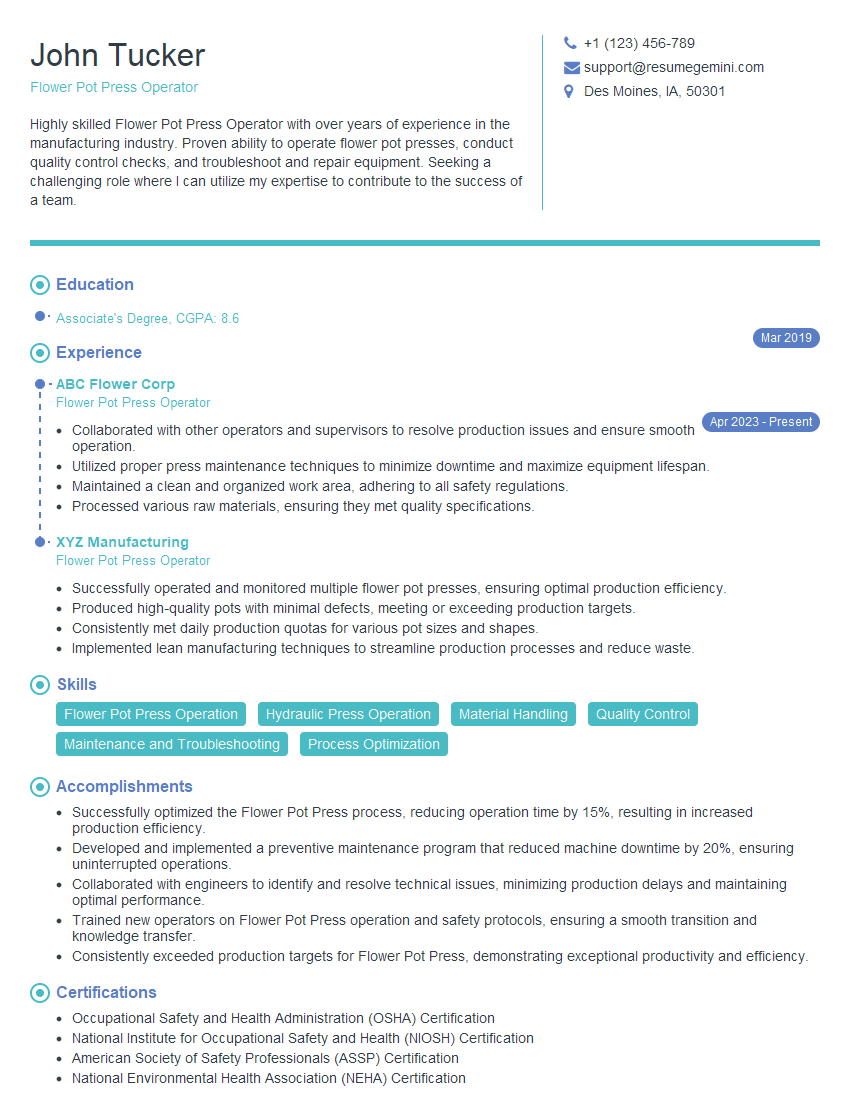

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flower Pot Press Operator

1. What is the procedure for loading raw materials into the flower pot press machine?

The procedure for loading raw materials into the flower pot press machine includes the following steps:

- Check the raw materials to ensure they are of the correct type and quality.

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Open the hopper of the press machine and pour the raw materials into it.

- Close the hopper and secure it properly.

- Start the press machine and allow the raw materials to be fed into the mold.

2. How do you ensure that the flower pots produced are of the correct size and shape?

Regular Inspections

- Conduct regular inspections of the press machine and molds to ensure they are in good working condition.

- Use measuring tools, such as calipers or rulers, to check the size and shape of the flower pots produced.

Quality Control

- Establish quality control procedures to monitor the production process and identify any deviations from specifications.

- Take corrective actions promptly to address any issues that arise.

3. What techniques do you use to troubleshoot common problems with the flower pot press machine?

Common problems with the flower pot press machine and their troubleshooting techniques include:

- Problem: Machine not starting or running erratically. Troubleshooting: Check power supply, electrical connections, and fuses. Inspect motor and drive system.

- Problem: Pots not forming correctly or breaking. Troubleshooting: Check mold alignment, pressure settings, and raw material consistency. Adjust parameters as needed.

- Problem: Excessive waste or material spillage. Troubleshooting: Inspect hopper, feeder, and mold for blockages or damage. Adjust material flow and settings.

4. How do you maintain the flower pot press machine to ensure its optimal performance?

To maintain the flower pot press machine for optimal performance:

- Regular cleaning: Remove dirt, debris, and excess materials from the machine regularly using brushes, compressed air, or cleaning solutions.

- Lubrication: Apply lubricants to moving parts, such as bearings and gears, according to the manufacturer’s instructions.

- Inspections: Conduct routine inspections of electrical components, hoses, and safety features to ensure proper functionality.

- Repairs and adjustments: Promptly address any identified issues or malfunctions to prevent further damage or downtime.

5. What safety precautions should be taken when operating the flower pot press machine?

When operating the flower pot press machine, it is crucial to adhere to the following safety precautions:

- PPE: Always wear appropriate personal protective equipment (PPE) including gloves, safety glasses, and a dust mask.

- Proper training: Ensure adequate training and authorization before operating the machine.

- Guarding: Verify that all guards and safety devices are in place and functioning correctly.

- Lockout/tagout: Follow proper lockout/tagout procedures before performing maintenance or repairs.

- Emergency stop: Familiarize yourself with the location and operation of the emergency stop button.

6. What is the role of temperature and pressure in the flower pot pressing process?

Temperature

- Elevated temperature softens the raw materials, making them more pliable for molding.

- Optimal temperature ensures proper bonding and reduces the risk of cracking or deformation.

Pressure

- Controlled pressure applied to the molds compresses the raw materials, shaping them into pots.

- Proper pressure distribution ensures uniform thickness and structural integrity of the pots.

7. How do you handle and store finished flower pots to prevent damage?

To handle and store finished flower pots effectively and prevent damage:

- Cooling: Allow pots to cool completely before handling to minimize thermal stress.

- Careful handling: Use gloves and handle pots gently to avoid chipping or cracking.

- Proper stacking: Stack pots on flat surfaces, ensuring stability and preventing deformation.

- Storage conditions: Store pots in a dry, well-ventilated area protected from moisture and direct sunlight.

8. What methods do you use to inspect the quality of finished flower pots?

To inspect the quality of finished flower pots, various methods are employed:

- Visual inspection: Examine pots for defects such as cracks, chips, or uneven surfaces.

- Dimensional checks: Use measuring tools to verify that pots meet specified dimensions and tolerances.

- Strength testing: Conduct tests to assess the structural integrity and load-bearing capacity of pots.

- Leak testing: Check for any leaks or water seepage through the pots.

9. How do you optimize production efficiency while operating the flower pot press machine?

To optimize production efficiency while operating the flower pot press machine:

- Setup optimization: Ensure proper setup of the machine, including mold alignment and pressure settings.

- Material preparation: Prepare raw materials adequately to minimize interruptions during production.

- Regular maintenance: Perform regular maintenance to prevent breakdowns and ensure smooth operation.

- Minimizing downtime: Identify and address potential bottlenecks to reduce downtime and increase productivity.

10. What techniques do you use to reduce waste and improve sustainability in the flower pot pressing process?

To reduce waste and improve sustainability, the following techniques are employed:

- Material optimization: Minimize raw material usage by optimizing mold design and reducing scrap.

- Recycling: Implement a recycling system to reuse excess or rejected materials.

- Energy efficiency: Use energy-efficient equipment and optimize production processes to reduce energy consumption.

- Water conservation: Employ water-saving techniques in cleaning and cooling processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flower Pot Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flower Pot Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Flower Pot Press Operator is an individual who is responsible for operating and maintaining flower pot presses in the manufacturing process of flower pots. Their main objective is to ensure the smooth and efficient production of high-quality flower pots.

1. Press Operation and Maintenance

A Flower Pot Press Operator is responsible for effectively managing flower pot presses. This entails setting up the press according to specifications, loading and unloading molds, and initiating the pressing process. Additionally, they must conduct regular maintenance on the press to ensure optimal performance and prevent breakdowns.

- Set up and adjust the flower pot press according to specific production requirements.

- Skillfully load and unload molds into the press, ensuring proper alignment and positioning.

- Control the pressing process by operating the press and monitoring various parameters, such as temperature, pressure, and cycle time.

- Perform preventive maintenance tasks, including cleaning, lubrication, and minor repairs, to maintain the press in good working condition.

- Identify and troubleshoot mechanical or electrical issues with the press, and take necessary corrective actions.

2. Quality Control and Inspection

A Flower Pot Press Operator plays a crucial role in ensuring the quality of flower pots produced. They visually inspect the finished pots for any defects or imperfections, such as cracks, chips, or uneven surfaces. By identifying and addressing quality issues, they ensure that only high-quality pots are released for sale.

- Thoroughly inspect the finished flower pots for any defects or non-conformities.

- Identify and remove defective pots from the production line, preventing them from being packaged and sold.

- Provide feedback to the production team to identify areas for improvement and maintain consistent quality standards.

- Adhere to established quality control procedures and follow industry best practices.

3. Production Monitoring and Optimization

A Flower Pot Press Operator is responsible for monitoring the production process and implementing strategies to optimize efficiency. They track production rates, identify bottlenecks, and make adjustments to maximize output while maintaining quality standards.

- Monitor the production process, including press speed, cycle time, and material consumption.

- Identify and analyze production bottlenecks and implement solutions to improve efficiency.

- Collaborate with the production team to optimize press settings and raw material usage.

- Suggest and implement process improvements to enhance productivity and reduce waste.

4. Safety and Compliance

A Flower Pot Press Operator is committed to maintaining a safe and compliant work environment. They adhere to all safety regulations and follow established procedures to prevent accidents and injuries. They also ensure that the work area is clean and organized, minimizing potential hazards.

- Strictly follow all established safety regulations and operating procedures.

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Maintain a clean and organized work area, free from tripping hazards and spills.

- Regularly inspect equipment and report any safety concerns or potential hazards to supervisors.

- Actively participate in safety training programs and stay updated on industry best practices.

Interview Tips

Preparing thoroughly for a Flower Pot Press Operator interview can significantly increase your chances of success. Here are some valuable tips to help you make a great impression and showcase your skills and qualifications.

1. Research the Company and Position

Before the interview, take the time to learn about the company you are applying to and the specific role you are seeking. Visit their website, read industry news and articles, and connect with current or former employees on LinkedIn. This will demonstrate your interest in the company and position and allow you to tailor your answers to their specific needs.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses in advance. Practice answering out loud to build confidence and ensure your answers are clear, concise, and relevant to the job responsibilities. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples of your skills and experience.

3. Highlight Your Technical Skills

Emphasize your technical skills and experience operating flower pot presses. Describe your proficiency in setting up, operating, and maintaining the equipment, as well as your ability to identify and troubleshoot any issues. Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency or quality.

4. Showcase Your Problem-Solving Abilities

Interviewers want to know that you can handle challenges and solve problems independently. Share examples of situations where you identified and resolved production issues, improved efficiency, or suggested process improvements. Explain your analytical approach and how you collaborated with others to find solutions.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions related to the company’s growth plans, industry trends, or specific aspects of the role that you are curious about. This demonstrates your enthusiasm and eagerness to learn more.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Flower Pot Press Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Flower Pot Press Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.