Are you gearing up for an interview for a Flowmeter Test and Certification Mechanic position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Flowmeter Test and Certification Mechanic and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

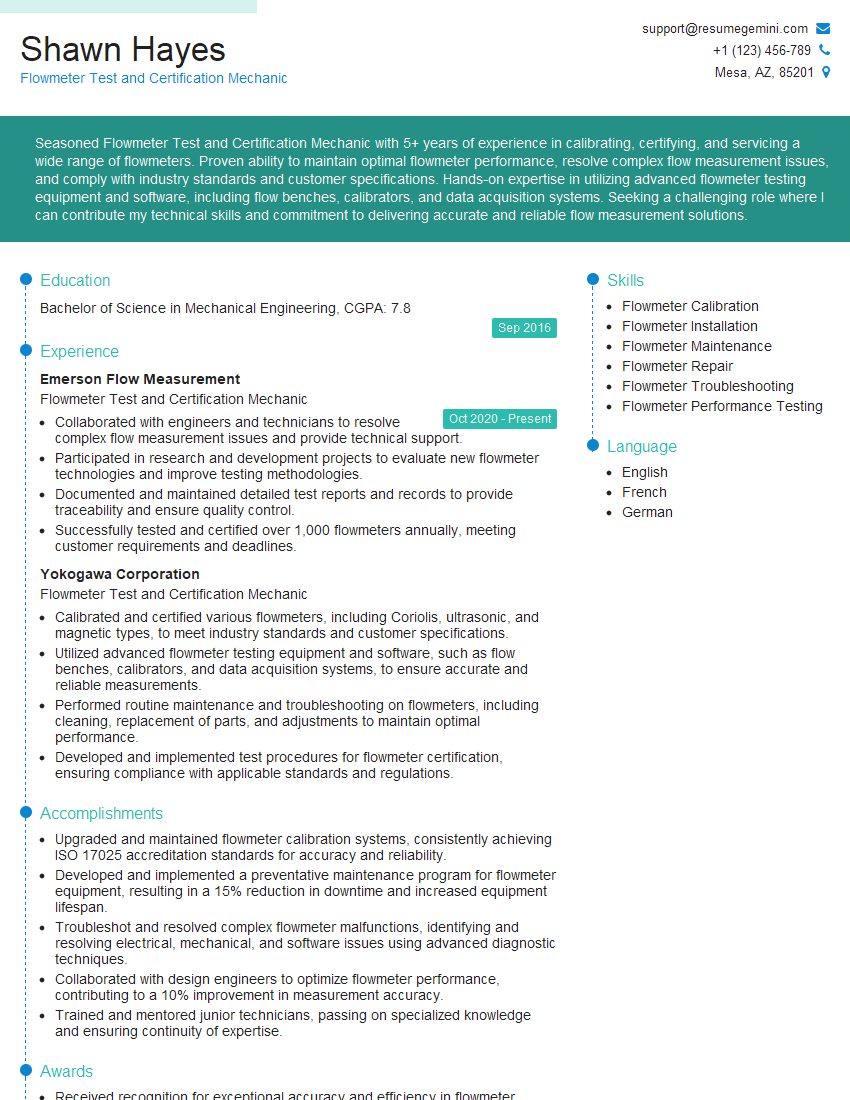

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flowmeter Test and Certification Mechanic

1. Describe the process of calibrating a flowmeter using a primary standard?

- Explain the importance of using a primary standard.

- Outline the steps involved in the calibration process.

- Discuss the need for traceability to national or international standards.

2. What are the different types of flowmeters and how do their operating principles differ?

Turbine flowmeters

- Principle: Blades rotate based on flow rate.

- Advantages: High accuracy, low pressure drop.

Coriolis flowmeters

- Principle: Oscillating tube, flow rate measured by Coriolis force.

- Advantages: Accuracy over wide flow ranges.

Ultrasonic flowmeters

- Principle: Ultrasonic waves sent upstream and downstream, time of flight difference measures flow rate.

- Advantages: Non-invasive, accurate for clean liquids and gases.

3. Explain the concept of fluid viscosity and how it affects the performance of flowmeters?

- Definition of viscosity and its units.

- Describe how viscosity affects flow rate and pressure drop.

- Discuss the importance of considering viscosity when selecting a flowmeter.

4. What are the key specifications to consider when selecting a flowmeter for a specific application?

- Flow rate range, accuracy requirements.

- Fluid compatibility, pressure and temperature ranges.

- Response time, power consumption, environmental conditions.

5. How do you approach troubleshooting a flowmeter that is not performing as expected?

- Inspect the flowmeter for physical issues.

- Check the calibration status and recalibrate if necessary.

- Examine the process conditions and ensure they are within the flowmeter’s specifications.

6. Describe the importance of flowmeter certification and what are the common industry standards used for certification?

- ISO 9001: Quality management system.

- OIML R 129: Tracer gas flowmeter testing.

- Benefits of certification: Enhanced accuracy, traceability, customer confidence.

7. How do you ensure that the flowmeter readings are accurate and reliable?

- Regular calibration using traceable standards.

- Proper installation and mounting of the flowmeter.

- Monitoring the process conditions to ensure they are stable.

8. What are the common challenges you have faced in your previous role as a Flowmeter Test and Certification Mechanic?

Example answer:

- Troubleshooting a flowmeter that was showing inconsistent readings due to a faulty sensor.

- Developing a calibration procedure for a new type of flowmeter.

- Interacting with customers to understand their specific flow measurement needs.

9. How do you stay up-to-date with the latest flowmeter technologies and industry best practices?

- Attending industry conferences and training.

- Reading technical journals and articles.

- Networking with other flowmeter professionals.

10. Describe a time when you successfully implemented a new flowmeter system in a challenging environment.

Example answer:

- Analyzed the customer’s flow measurement needs.

- Selected and recommended an appropriate flowmeter.

- Installed and calibrated the flowmeter.

- Trained the customer’s staff on the operation and maintenance of the flowmeter.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flowmeter Test and Certification Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flowmeter Test and Certification Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Flowmeter Test and Certification Mechanic is responsible for the testing, calibration, and certification of flowmeters used in various industries. Their primary duties include:

1. Flowmeter Testing and Calibration

Conducting comprehensive testing and calibration of flowmeters using advanced calibration equipment and techniques.

- Verifying the accuracy and performance of flowmeters against industry standards and specifications.

- Adjusting and repairing flowmeters to ensure optimal performance and compliance with regulatory requirements.

2. Certification and Documentation

Issuing certificates of calibration and test reports that document the performance and accuracy of flowmeters.

- Maintaining detailed records of all testing and calibration activities for traceability and compliance.

- Providing technical support and guidance to customers regarding flowmeter operation and maintenance.

3. Troubleshooting and Repair

Diagnosing and resolving issues with flowmeters, including electrical faults, mechanical failures, and performance degradation.

- Performing repairs and replacements of flowmeter components to ensure proper functioning.

- Collaborating with engineers and technicians to identify and address complex flowmeter problems.

4. Quality Control and Compliance

Adhering to strict quality control procedures and industry standards throughout the testing and certification process.

- Ensuring compliance with regulatory requirements and customer specifications.

- Maintaining knowledge of industry best practices and advancements in flowmeter technology.

Interview Tips

Preparing for an interview for the Flowmeter Test and Certification Mechanic position requires thorough research and showcasing your technical skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry standing. Learn about their flowmeter testing and certification practices and understand the latest advancements in flowmeter technology.

- Visit the company’s website, read industry publications, and attend relevant webinars or conferences.

- Network with professionals in the field to gain insights and expand your knowledge.

2. Highlight Your Technical Expertise

Emphasize your strong understanding of flowmeter principles, testing methodologies, and calibration techniques. Describe your experience in using calibration equipment and software, and discuss any specific certifications or training you have received.

- Prepare examples of complex flowmeter issues you have successfully resolved.

- Explain your approach to troubleshooting and repairing flowmeters, providing specific technical details.

3. Demonstrate Your Quality Control Skills

Showcase your commitment to quality and compliance by highlighting your attention to detail, adherence to procedures, and ability to maintain accurate records. Explain your understanding of industry regulations and standards, and discuss any quality control measures you have implemented.

- Provide examples of how you have ensured the accuracy and reliability of flowmeter testing results.

- Discuss your experience in developing or implementing quality control processes.

4. Prepare for Common Interview Questions

Anticipate questions about your technical skills, experience with specific flowmeter types, and your problem-solving abilities. Practice answering questions such as:

- Describe your experience in calibrating and testing different types of flowmeters.

- How do you approach troubleshooting a complex flowmeter issue?

- What are the key industry regulations and standards you are familiar with?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flowmeter Test and Certification Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!