Feeling lost in a sea of interview questions? Landed that dream interview for Fluid Jet Cutter Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Fluid Jet Cutter Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

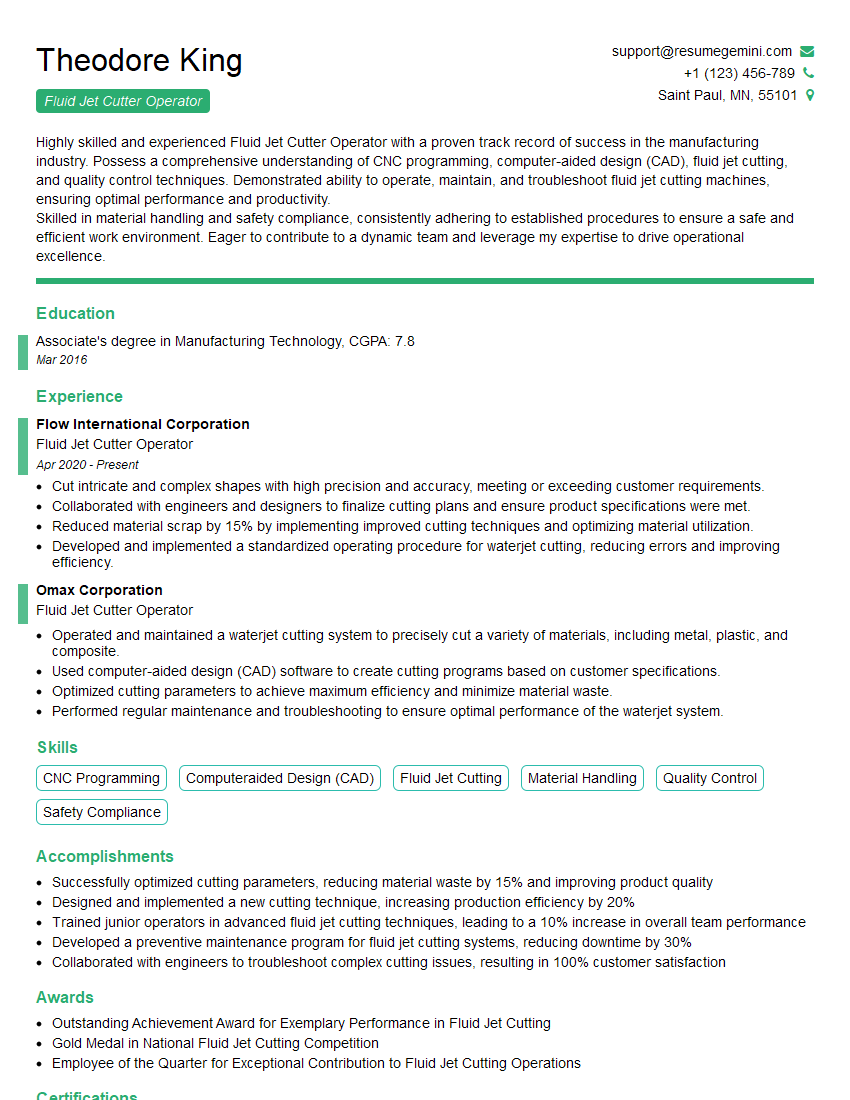

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fluid Jet Cutter Operator

1. Describe the process of operating a Fluid Jet Cutter.

- Load the material to be cut onto the machine bed.

- Program the machine with the desired cutting pattern.

- Start the cutting process and monitor it to ensure that it is proceeding as expected.

- Remove the finished cut from the machine bed.

2. What are the different types of materials that can be cut with a Fluid Jet Cutter?

- Metals

- Plastics

- Ceramics

- Glass

- Wood

3. What are the advantages of using a Fluid Jet Cutter over other cutting methods?

- Can cut a wide variety of materials

- Produces clean, precise cuts

- Does not generate heat, so there is no risk of damaging the material being cut

- Is relatively safe to operate

4. What are the different types of abrasives that can be used with a Fluid Jet Cutter?

- Ceramic

- Garnet

- Aluminum oxide

- Silicon carbide

Advantages and Disadvantages of each

- Ceramic: Hard, durable, and produces a fine finish, but can be expensive.

- Garnet: Medium hardness, relatively inexpensive, and produces a good finish.

- Aluminum oxide: Hard and durable, but can produce a rougher finish than ceramic or garnet.

- Silicon carbide: Very hard and durable, but can be expensive and produce a rougher finish than ceramic or garnet.

5. What is the role of the water jet in the cutting process?

- Carries the abrasive particles to the cutting surface

- Cools the cutting surface

- Removes the cut material from the cutting area

6. What are the different types of water jets that can be used?

- Pure water jet

- Abrasive water jet

Advantages and Disadvantages of each

- Pure water jet: Can cut very thin materials without damaging them, but is not as powerful as an abrasive water jet.

- Abrasive water jet: Can cut a wider range of materials than a pure water jet, but can damage thin materials.

7. What are the safety precautions that must be taken when operating a Fluid Jet Cutter?

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Be aware of the hazards associated with the machine, such as the high-pressure water jet and the rotating cutting head.

- Follow all operating procedures carefully.

- Do not attempt to service the machine yourself.

8. What are the common problems that can occur with a Fluid Jet Cutter?

- Clogged nozzles

- Leaking water jets

- Faulty cutting heads

- Software errors

9. How do you troubleshoot a Fluid Jet Cutter?

- Identify the problem.

- Consult the machine manual for troubleshooting tips.

- Contact the machine manufacturer for support.

10. What are the maintenance requirements for a Fluid Jet Cutter?

- Regularly clean and lubricate the machine.

- Check the water jet nozzles for wear and tear.

- Inspect the cutting head for damage.

- Update the machine software as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fluid Jet Cutter Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fluid Jet Cutter Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fluid Jet Cutter Operators are responsible for operating and maintaining fluid jet cutting equipment. They use high-pressure water or abrasive jets to cut a variety of materials, including metal, plastic, and glass.

1. Set up and operate fluid jet cutting equipment

This involves:

- Loading and unloading materials

- Setting up cutting parameters, such as water pressure and abrasive flow rate

- Monitoring the cutting process to ensure that it is accurate and efficient

2. Maintain fluid jet cutting equipment

This involves:

- Cleaning and lubricating the equipment

- Inspecting the equipment for wear and damage

- Replacing worn or damaged parts

3. Quality control

Fluid Jet Cutter Operators are responsible for ensuring that the parts they produce meet the required specifications. This involves:

- Inspecting parts for defects

- Measuring parts to ensure that they meet the required dimensions

- Making adjustments to the cutting process to improve quality

4. Safety

Fluid Jet Cutter Operators must follow all safety procedures to avoid injury to themselves and others. This includes:

- Wearing appropriate safety gear

- Following lockout/tagout procedures

- Keeping the work area clean and organized

Interview Tips

Here are some tips to help you ace your interview for a Fluid Jet Cutter Operator position:

1. Research the company and the position

This will help you understand the company’s culture and the specific requirements of the position. Be prepared to discuss your qualifications and how they match the job requirements.

2. Practice your answers to common interview questions

Some common interview questions for Fluid Jet Cutter Operators include:

- Tell me about your experience operating fluid jet cutting equipment.

- What are your strengths and weaknesses as a Fluid Jet Cutter Operator?

- How do you handle quality control issues?

- What is your safety record?

3. Be prepared to talk about your experience with different materials

Fluid Jet Cutter Operators can cut a variety of materials, including metal, plastic, and glass. Be prepared to discuss your experience with different materials and the challenges you have faced.

4. Be enthusiastic and positive

Employers are looking for candidates who are passionate about their work. Be enthusiastic and positive during your interview, and highlight your passion for fluid jet cutting.

Next Step:

Now that you’re armed with the knowledge of Fluid Jet Cutter Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Fluid Jet Cutter Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini