Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Fly Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

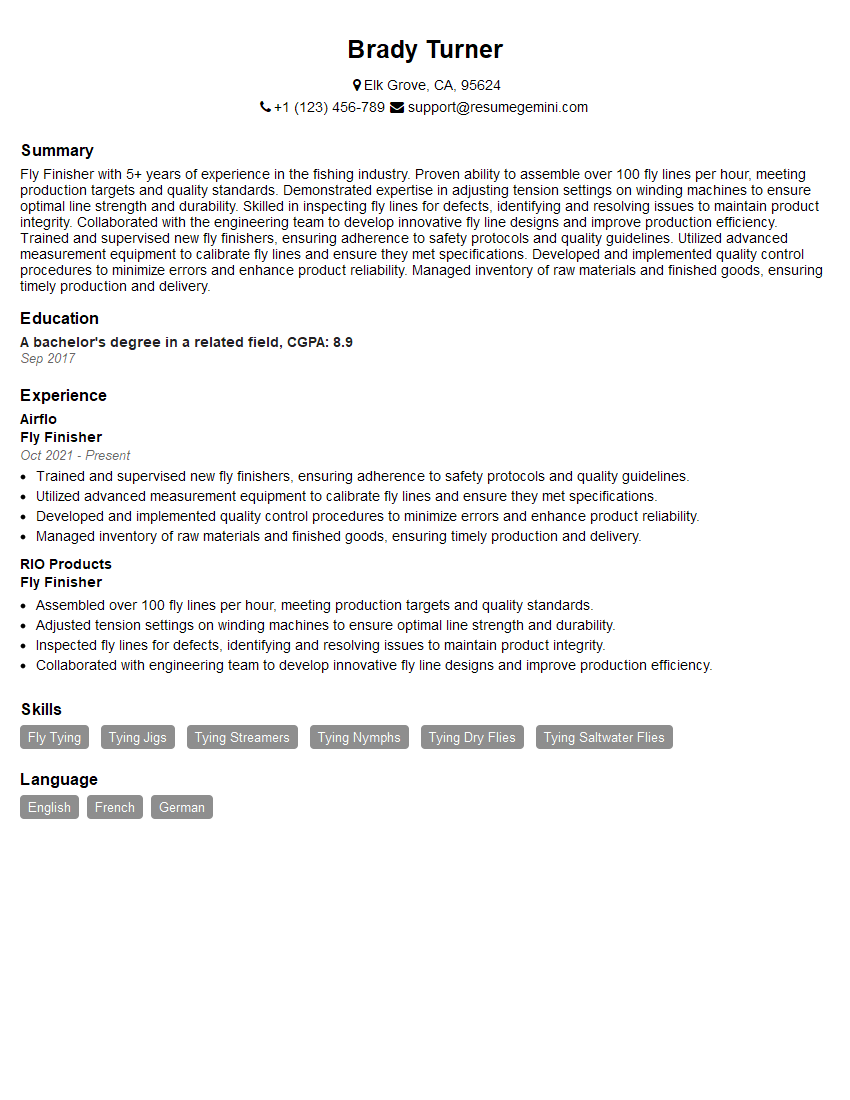

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Fly Finisher

1. Describe the process of fly finishing and the different stages involved?

Fly finishing is the final stage in the production of flies, which involves applying a finish to the fly to improve its appearance, durability, and effectiveness as a fishing lure. The process typically involves several stages:

- Cleaning and inspecting the fly: The fly is cleaned to remove any dirt or debris, and inspected for any defects or imperfections.

- Applying a base coat: A thin coat of epoxy or other material is applied to the fly to provide a smooth, even surface for the final finish.

- Applying the final finish: The final finish is applied, which can be a variety of materials such as paint, varnish, or lacquer. This finish protects the fly from the elements and helps it to retain its shape.

- Curing the finish: The fly is allowed to cure for a period of time, which allows the finish to fully cure and harden.

2. What are the different techniques used for applying finishes to flies?

Airbrushing:

- Uses a specialized tool to spray paint or other finishes onto the fly, allowing for precise control over the application and creating detailed designs.

- Requires skill and practice to master.

Hand painting:

- Involves using a brush to apply paint or other finishes to the fly, allowing for greater versatility and flexibility.

- Can be more time-consuming and requires a steady hand.

Dipping:

- Consists of submerging the fly in a container of finish, providing a quick and easy way to apply a consistent coating.

- May result in a less precise finish compared to other techniques.

Other techniques:

- Powder coating: Applying a powdered finish to the fly, which is then heated to melt and cure it.

- Electroplating: Using an electrical current to deposit a metallic finish on the fly.

3. What are the key factors to consider when selecting a finish for a fly?

- Durability: The finish should be able to withstand the wear and tear of fishing, such as exposure to water, sunlight, and abrasion.

- Appearance: The finish should enhance the appearance of the fly and make it more attractive to fish.

- Weight: The finish should not add too much weight to the fly, as this can affect its casting and fishing performance.

- Toxicity: The finish should not be toxic to fish or the environment.

4. How do you ensure that the finishes applied to flies are consistent and meet quality standards?

- Establish clear specifications: Define the desired appearance, durability, and other requirements for the finishes.

- Use high-quality materials: Choose finishes that are known for their durability and consistency.

- Follow standardized procedures: Develop and adhere to specific protocols for applying finishes, including proper mixing ratios, application techniques, and curing times.

- Conduct regular inspections: Inspect finished flies to ensure they meet the established quality standards, and make adjustments as necessary.

- Seek feedback from anglers: Gather feedback from anglers who use your flies to identify any areas for improvement in the finishing process.

5. What are the common challenges faced in fly finishing and how do you overcome them?

- Achieving consistent finishes: Overcome by using standardized procedures, high-quality materials, and regular inspections.

- Ensuring durability: Overcome by selecting durable finishes and applying them correctly, following proper curing times.

- Maintaining productivity: Overcome by optimizing the finishing process, using efficient techniques, and streamlining workflow.

- Meeting customer expectations: Overcome by clearly understanding customer requirements, communicating effectively, and delivering finished products that meet or exceed those expectations.

6. What are the latest trends and advancements in fly finishing techniques?

- Use of UV-curable finishes: These finishes cure quickly under UV light, allowing for faster production times.

- Incorporation of 3D printing: 3D printing can be used to create custom fly bodies and other components with complex shapes.

- Development of new materials: New materials are being developed that offer improved durability, flexibility, and other desirable properties for fly finishes.

- Integration of technology: Technology is being used to improve the accuracy and efficiency of fly finishing processes, such as computerized mixing and application systems.

7. How do you stay up-to-date with the latest advancements and best practices in fly finishing?

- Attend industry events: Attend trade shows, workshops, and conferences to learn about new products, techniques, and industry trends.

- Read industry publications: Subscribe to fly fishing magazines and online resources to stay informed about the latest advancements.

- Connect with other fly finishers: Network with other professionals in the field to exchange ideas and learn from their experiences.

- Experiment with new techniques: Dedicate time to experimenting with different finishing techniques and materials to improve your skills and explore new possibilities.

8. What is your approach to quality control in fly finishing?

- Establish clear standards: Define specific quality standards for the appearance, durability, and other aspects of finished flies.

- Inspect finished flies: Regularly inspect finished flies to ensure they meet the established quality standards.

- Identify and address defects: Promptly identify and address any defects or non-conformances in the finishing process.

- Document quality control processes: Maintain records and documentation of quality control procedures to ensure consistency and accountability.

9. How do you handle customer feedback and complaints regarding fly finishes?

- Acknowledge and apologize: Acknowledge the customer’s concerns and apologize for any dissatisfaction.

- Investigate the issue: Thoroughly investigate the issue to determine the cause of the complaint.

- Provide a solution: Offer a solution to the customer, such as a replacement fly or a refund, if appropriate.

- Follow up: Follow up with the customer to ensure their satisfaction and to gather any additional feedback.

10. What are your strengths and weaknesses as a fly finisher?

Strengths:- Excellent attention to detail and precision in applying finishes.

- Strong understanding of different fly finishing techniques and materials.

- Proven ability to produce high-quality, durable, and aesthetically pleasing flies.

- Limited experience in using advanced finishing techniques, such as airbrushing.

- Sometimes I may be slow in meeting large orders due to my focus on quality and precision.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Fly Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Fly Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Fly Finishers play a vital role in the manufacturing process, preparing and finishing components for assembly. Their key responsibilities include:

1. Deburring and Cleaning

Removing sharp edges and burrs from components using tools like files, sandpaper, or deburring machines.

2. Polishing and Buffing

Improving the surface finish and removing imperfections using abrasive materials like sandpaper, polishing wheels, or buffing compounds.

3. Inspection and Quality Control

Inspecting finished components to ensure they meet required specifications and quality standards.

4. Assembly Preparation

Preparing components for assembly by cleaning, applying adhesives, or performing light assembly tasks.

Interview Tips

To ace the interview for a Fly Finisher position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This demonstrates your interest and enthusiasm.

- Example: Visit the company website, read industry news, and explore similar job roles.

2. Highlight Your Technical Skills

Emphasize your proficiency in deburring, polishing, and inspection techniques. Quantify your experience and provide specific examples of projects you’ve worked on.

- Example: “I have over 5 years of experience in deburring metal components using various methods, including hand filing, abrasive blasting, and automated machines.”

3. Showcase Your Quality Consciousness

Demonstrate your commitment to quality by highlighting your attention to detail and adherence to specifications. Mention any certifications or training you have in quality control.

- Example: “I am Six Sigma Green Belt certified and have successfully implemented quality improvement initiatives in my previous role, reducing defect rates by 20%.”

4. Prepare for Common Interview Questions

Research typical interview questions for Fly Finisher positions and prepare your answers accordingly. Consider the STAR method (Situation, Task, Action, Result) to structure your responses.

- Example: “Describe a time when you identified and resolved a quality issue in a finished component.” (STAR response: Situation: Discovered a surface irregularity during inspection; Task: Analyzed the defect and determined its cause; Action: Used a polishing wheel to remove the irregularity; Result: Component passed quality control and met customer specifications.)

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Fly Finisher role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.