Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Flying Shear Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Flying Shear Operator so you can tailor your answers to impress potential employers.

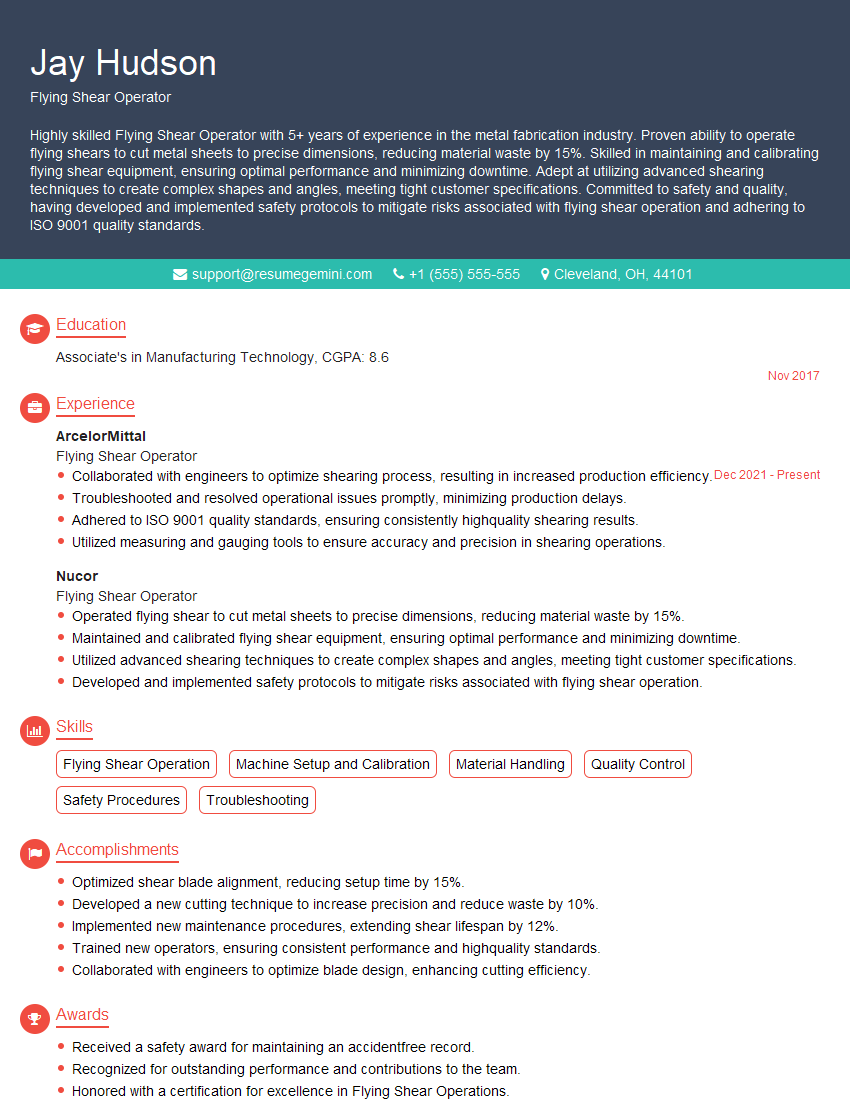

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Flying Shear Operator

1. What are the key responsibilities of a Flying Shear Operator?

- Operating and maintaining flying shear equipment

- Positioning and cutting metal sheets using the flying shear

- Ensuring proper alignment and accuracy of cuts

- Monitoring equipment performance and conducting routine maintenance

- Adhering to safety regulations and following established procedures

2. What are the different types of flying shears?

Guillotine Flying Shears

- Used for precise and high-volume cutting of metal sheets

- Features a stationary lower blade and a movable upper blade

Rotary Flying Shears

- Designed for cutting curved and irregular shapes in metal sheets

- Employs a spinning blade to cut the material

Double-Head Flying Shears

- Equipped with two cutting heads that simultaneously cut two parallel lines

- Ideal for slitting metal coils and sheets

3. How do you ensure the accuracy of cuts made using a flying shear?

- Properly calibrating the shear to the specified cutting length

- Using precision measuring tools to set the material position

- Inspecting the alignment of the material and blade before each cut

- Maintaining sharp cutting blades to ensure clean and accurate cuts

4. Describe your experience in troubleshooting and resolving common flying shear problems.

- Identifying and correcting blade misalignment issues

- Troubleshooting electrical and mechanical malfunctions

- Performing preventive maintenance to minimize downtime

- Collaborating with maintenance technicians to resolve complex issues

5. What safety precautions should be taken when operating a flying shear?

- Wearing appropriate personal protective equipment (PPE)

- Keeping the work area clean and free of debris

- Ensuring proper ventilation to prevent dust accumulation

- Following all manufacturer’s safety instructions and guidelines

6. How do you optimize the performance of a flying shear?

- Using the appropriate cutting speed and blade type for the material being cut

- Adjusting the blade gap to minimize burr formation

- Regularly lubricating the machine and performing maintenance checks

- Monitoring the equipment’s performance and making adjustments as needed

7. What are the different types of materials that can be cut using a flying shear?

- Mild steel

- Stainless steel

- Aluminum

- Brass

- Copper

8. How do you determine the appropriate cutting speed for different materials?

- Referencing manufacturer’s guidelines or industry standards

- Considering the thickness and type of material being cut

- Conducting trial cuts and adjusting the speed accordingly

9. What are the common quality defects that can occur during flying shear cutting?

- Burr formation

- Edge waviness

- Inaccurate cuts

- Surface scratches

- Material deformation

10. How do you maintain a safe and efficient work environment when operating a flying shear?

- Following all safety protocols and procedures

- Maintaining a clean and organized work area

- Using proper lifting techniques when handling materials

- Communicating effectively with coworkers to ensure safety

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Flying Shear Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Flying Shear Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Flying Shear Operators are responsible for operating and maintaining flying shears, which are used to cut metal sheets into desired shapes and sizes. The key job responsibilities of a Flying Shear Operator include:

1. Operating the flying shear

Flying Shear Operators are responsible for setting up and operating the flying shear according to the required specifications. This includes setting the blade gap, shear speed, and feed rate. They must also monitor the shear’s operation and make adjustments as needed.

- Setting up the flying shear according to the required specifications

- Operating the flying shear to cut metal sheets into desired shapes and sizes

- Monitoring the shear’s operation and making adjustments as needed

2. Maintaining the flying shear

Flying Shear Operators are responsible for maintaining the flying shear in good working condition. This includes cleaning and lubricating the shear, replacing worn parts, and making minor repairs. They must also follow established safety procedures to prevent accidents.

- Cleaning and lubricating the shear

- Replacing worn parts

- Making minor repairs

- Following established safety procedures

3. Inspecting metal sheets

Flying Shear Operators are responsible for inspecting metal sheets before and after cutting. This includes checking for defects, such as scratches, dents, or burrs. They must also ensure that the metal sheets are cut to the correct dimensions.

- Inspecting metal sheets before and after cutting

- Checking for defects, such as scratches, dents, or burrs

- Ensuring that the metal sheets are cut to the correct dimensions

4. Troubleshooting problems

Flying Shear Operators are responsible for troubleshooting problems that may occur with the flying shear. This includes identifying the cause of the problem and taking steps to resolve it. They must also be able to communicate effectively with maintenance personnel to ensure that the shear is repaired quickly and efficiently.

- Identifying the cause of the problem

- Taking steps to resolve the problem

- Communicating effectively with maintenance personnel

Interview Tips

To prepare for an interview for a Flying Shear Operator position, it is important to:

1. Research the company and the position

Before the interview, take some time to research the company and the specific Flying Shear Operator position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position. You can find this information on the company’s website, LinkedIn page, and other online resources.

- Visit the company’s website

- Check the company’s LinkedIn page

- Read online reviews of the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely. You can also prepare for specific questions related to the Flying Shear Operator position, such as “What is your experience with flying shears?” and “How do you troubleshoot problems with flying shears?”

- Common interview questions

- Flying Shear Operator specific questions

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview, as this shows that you are respectful of the interviewer’s time. You should also be prepared to answer questions about your experience and qualifications, and to provide examples of your work. You should also be prepared to ask questions about the company and the position, as this shows that you are interested in the opportunity.

- Dress professionally

- Arrive on time

- Be prepared to answer questions

- Ask questions about the company and the position

4. Be enthusiastic and confident

Interviewers are looking for candidates who are enthusiastic about the position and who are confident in their abilities. You should be able to articulate your skills and experience in a clear and concise manner, and you should be able to answer questions about your experience and qualifications confidently. You should also be able to demonstrate your passion for the Flying Shear Operator position, and you should be able to explain why you are the best candidate for the job.

- Be enthusiastic

- Be confident

- Articulate your skills and experience

- Demonstrate your passion for the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Flying Shear Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!