Are you gearing up for a career in Foam Rubber Fabricator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Foam Rubber Fabricator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

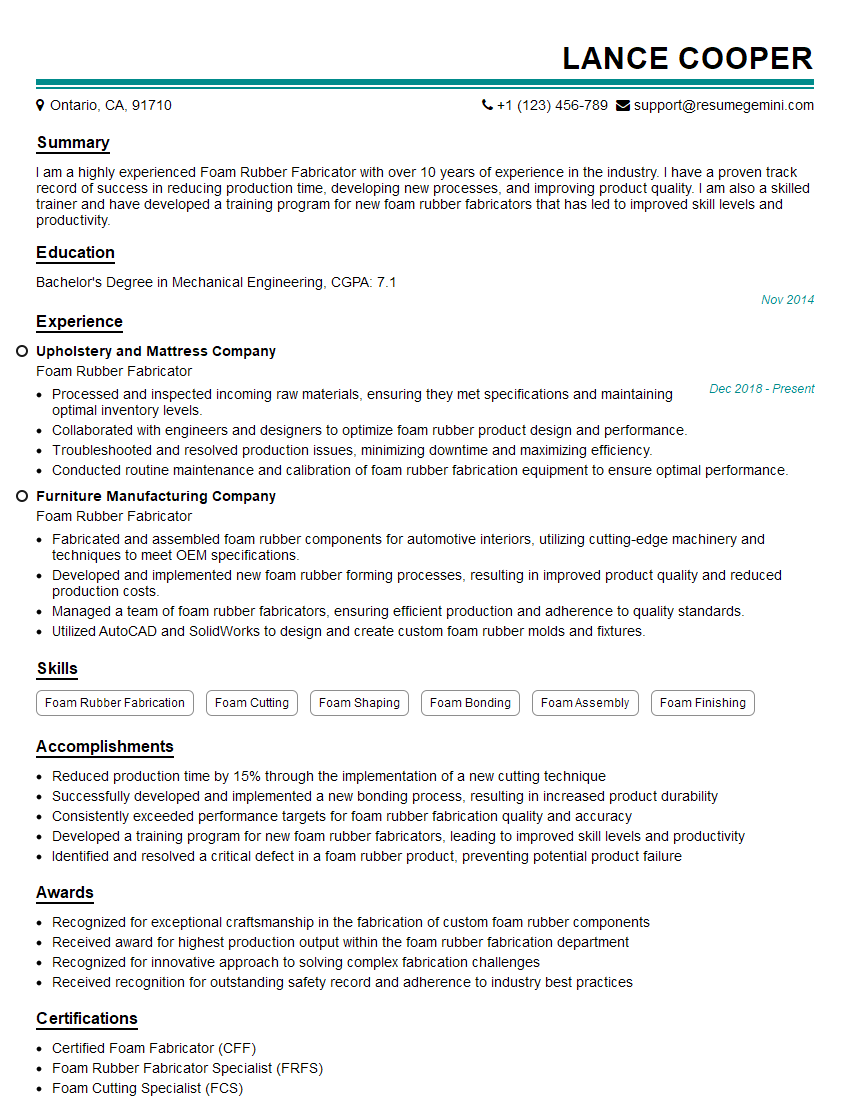

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foam Rubber Fabricator

1. What is the process of foam rubber fabrication?

Foam rubber fabrication involves converting raw foam rubber into finished products. It typically includes the following steps:

- Selecting the right foam: Choosing the appropriate foam density, firmness, and type for the intended application.

- Cutting the foam: Using specialized tools like CNC routers or water jets to precisely cut the foam into desired shapes.

- Shaping the foam: Molding or shaping the foam using heat, pressure, or adhesives to create complex contours and dimensions.

- Finishing the foam: Applying coatings, laminating, or adding other materials to enhance the foam’s properties or appearance.

2. What are the different types of foam rubber and their uses?

Open-cell foam:

- Breathable and moisture-wicking

- Used in mattresses, upholstery, and packaging

Closed-cell foam:

- Airtight and water-resistant

- Used in buoyancy aids, insulation, and gaskets

Memory foam:

- Conforms to body shape and provides support

- Used in mattresses, pillows, and orthopedic products

3. What are the key properties to consider when selecting foam rubber?

When selecting foam rubber, consider the following properties:

- Density: Affects firmness and support

- Hardness: Resistance to deformation

- Resilience: Ability to recover its shape after compression

- Thermal conductivity: Insulation properties

- Fire resistance: Safety considerations

4. What are the different methods used to cut foam rubber?

Foam rubber can be cut using various methods, including:

- CNC routing: Computer-controlled machine for precise and complex cuts

- Water jet cutting: High-pressure water stream for intricate and clean cuts

- Die cutting: Using sharp dies to punch out shapes from the foam

- Band sawing: Using a continuous band saw for straight and curved cuts

5. How do you ensure the quality of foam rubber products?

Quality assurance measures for foam rubber products include:

- Raw material inspection: Verifying foam density, hardness, and other properties

- Process control: Monitoring cutting, shaping, and finishing steps to meet specifications

- Dimensional accuracy: Ensuring products meet precise dimensions and tolerances

- Appearance inspection: Checking for surface defects, color consistency, and overall finish

- Performance testing: Evaluating properties like resilience, compression resistance, and durability

6. What are some common challenges faced in foam rubber fabrication and how do you address them?

Challenges and solutions in foam rubber fabrication include:

- Tearing: Using sharp cutting tools and proper handling techniques

- Deformation: Ensuring precise cutting and shaping, using supportive materials if needed

- Inconsistent density: Selecting foam with uniform density and using appropriate cutting methods

- Surface imperfections: Paying attention to finishing processes and using high-quality materials

7. What is your experience with foam rubber bonding and lamination?

In foam rubber bonding and lamination, I have worked with various adhesives and techniques, including:

- Contact adhesives: Applying adhesive to both surfaces and pressing them together

- Laminating adhesives: Using heat or pressure to bond foam layers with laminates

- Hot melt adhesives: Applying molten adhesive to surfaces and bonding under heat

- Pressure-sensitive adhesives: Using self-adhesive materials to bond foam

8. How do you handle complex foam rubber shapes and intricate designs?

For complex shapes and intricate designs in foam rubber fabrication, I utilize specialized techniques such as:

- CNC routing with complex programming: Creating precise and detailed cuts

- Water jet cutting with custom nozzles: Achieving intricate contours and sharp corners

- Molding and shaping: Using heat and pressure to form complex shapes

- Handcrafting and prototyping: Developing custom solutions for unique designs

9. What is your knowledge of foam rubber recycling and sustainability practices?

I am aware of the importance of sustainability in foam rubber fabrication and have experience in:

- Using eco-friendly materials: Selecting foams made from recycled or renewable sources

- Reducing waste: Optimizing cutting patterns and minimizing scrap

- Proper disposal and recycling: Following regulations and working with waste management partners

10. How do you stay updated with the latest advances in foam rubber technology and industry trends?

To stay updated on foam rubber technology and industry trends, I:

- Attend industry events and conferences: Connecting with experts and learning about innovations

- Read trade publications and online resources: Staying informed about new materials and techniques

- Participate in online forums and discussions: Engaging with professionals and sharing knowledge

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foam Rubber Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foam Rubber Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foam Rubber Fabricators are responsible for producing and shaping foam rubber products used in various industries, such as automotive, furniture, and construction. Their duties involve cutting, bonding, and shaping foam rubber to meet specific customer requirements.

1. Cutting and Shaping Foam Rubber

Using precision cutting tools and machinery, foam rubber fabricators cut foam rubber into desired shapes and sizes based on customer specifications. They may use computer-aided design (CAD) software to ensure accuracy.

- Operate cutting equipment, including saws, knives, and CNC machines.

- Follow cutting diagrams and specifications to ensure precise cuts.

2. Bonding and Assembly

Foam rubber fabricators bond and assemble foam rubber pieces using adhesives, sealants, and fasteners to create complex shapes and products. They may also perform sewing and stitching operations.

- Apply adhesives and sealants to bond foam rubber pieces.

- Assemble and fasten foam rubber components to create complete products.

3. Quality Control

Foam rubber fabricators inspect and test finished products to ensure they meet quality standards and customer specifications. They may use measuring tools, gauges, and inspection equipment to verify dimensions, shape, and performance.

- Perform quality checks and inspections throughout the production process.

- Identify and correct defects or non-conformance issues.

4. Equipment Maintenance

Foam rubber fabricators are responsible for maintaining and calibrating cutting and bonding equipment to ensure optimal performance and safety. They may perform routine maintenance tasks, such as cleaning, lubrication, and blade sharpening.

- Maintain and calibrate cutting and bonding equipment.

- Identify and replace worn or damaged parts.

Interview Tips

Preparing for an interview for a Foam Rubber Fabricator position requires thorough research, practicing common interview questions, and presenting oneself professionally and confidently.

1. Research the Company and Position

Before the interview, take time to learn about the company’s history, values, and products. Familiarize yourself with the specific job description and responsibilities. This knowledge will help you tailor your answers and demonstrate your interest in the position.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Practice Common Interview Questions

Prepare for typical interview questions by practicing your responses. Anticipate questions about your experience, skills, and qualifications. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Describe your experience in cutting and shaping foam rubber.

- Explain how you ensure quality control in your work.

3. Showcase Your Skills and Experience

During the interview, highlight your relevant skills and experience that align with the job requirements. Emphasize your precision cutting abilities, bonding techniques, and understanding of quality control processes.

- Provide specific examples of your work that demonstrate your skills.

- Quantify your accomplishments whenever possible.

4. Demonstrate Your Work Ethic

Foam rubber fabrication requires a strong work ethic and attention to detail. Show the interviewer that you are reliable, hardworking, and committed to producing high-quality products on time.

- Emphasize your punctuality and attendance record.

- Explain how you manage your time and meet deadlines.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Foam Rubber Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!