Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Foam Rubber Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

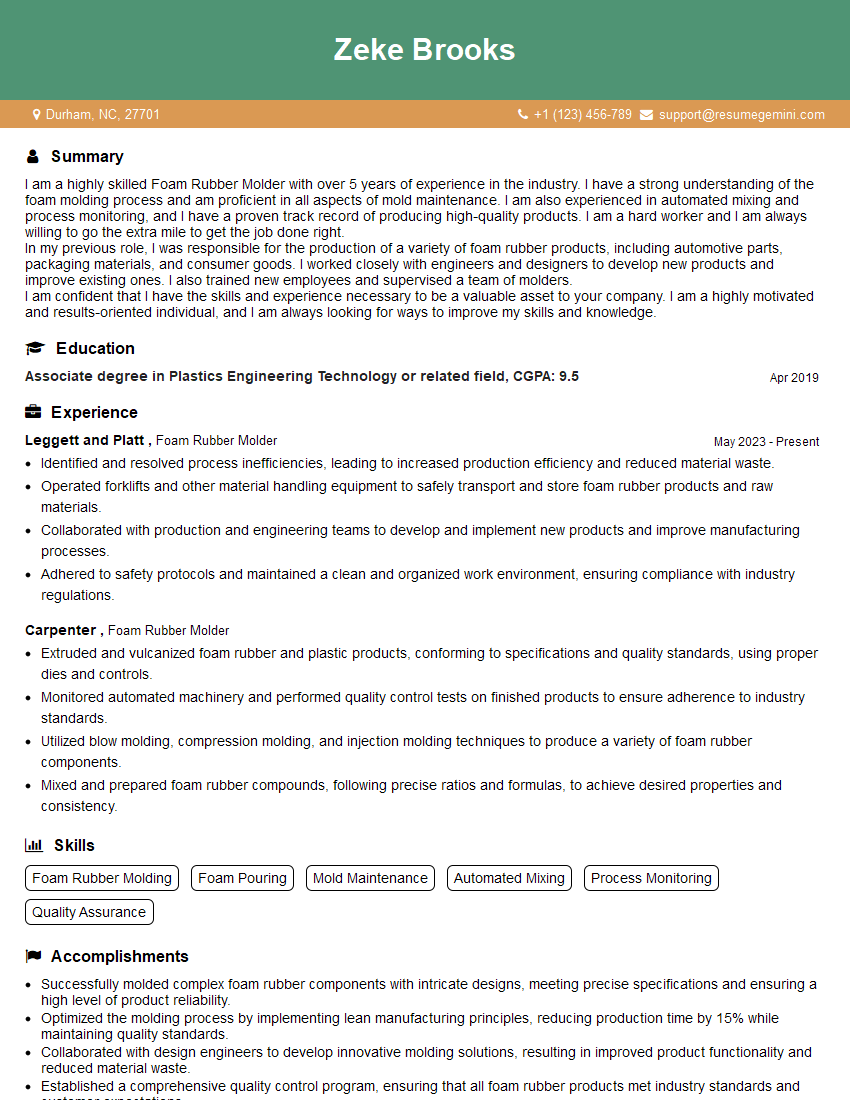

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foam Rubber Molder

1. What are the key steps involved in the foam rubber molding process?

The key steps involved in the foam rubber molding process are:

- Mixing: Raw materials, including rubber, foaming agents, and other additives, are mixed together.

- Molding: The mixed material is poured into a mold and heated to initiate the foaming process.

- Expansion: The foaming agents create gas bubbles within the rubber, causing it to expand and fill the mold.

- Curing: The molded foam is then heated further to complete the vulcanization process and cross-link the rubber, giving it its desired properties.

- Demolding: Once cured, the foam product is removed from the mold.

- Finishing: The finished foam may undergo additional processes such as trimming, shaping, or coating, depending on the specific application.

2. Explain the role of foaming agents in foam rubber production.

Foaming agents play a crucial role in foam rubber production by creating gas bubbles within the rubber material.

Types of Foaming Agents

- Physical Blowing Agents: Release gases, such as nitrogen or carbon dioxide, when heated.

- Chemical Blowing Agents: Decompose when heated, releasing gases like nitrogen or carbon dioxide.

Functions of Foaming Agents

- Create Gas Bubbles: Generate a uniform distribution of gas bubbles throughout the rubber mixture.

- Control Foam Density: The amount and type of foaming agent used determine the density and texture of the resulting foam.

- Influence Foam Properties: The choice of foaming agent affects the foam’s mechanical strength, thermal insulation, and other properties.

3. Describe the different types of foam rubber molds.

There are various types of foam rubber molds used in the molding process:

- Open Mold: Allows the foam to expand freely, creating a less dense and more flexible foam.

- Closed Mold: Restricts the foam’s expansion, resulting in a denser and stiffer foam.

- Compression Mold: Uses a press to compress the foam, producing a dense and uniform foam with a smooth surface.

- Injection Mold: Injects the foam mixture into a closed mold, achieving precise shaping and higher foam density.

4. How do you ensure the quality of the finished foam rubber products?

Ensuring the quality of finished foam rubber products requires a comprehensive approach:

- Raw Material Control: Inspecting incoming raw materials to verify their quality and consistency.

- Process Monitoring: Closely monitoring the molding process parameters, such as temperature, pressure, and mixing time, to ensure adherence to specifications.

- In-Process Testing: Conducting regular tests on samples taken during production to assess foam density, hardness, elasticity, and other properties.

- Finished Product Inspection: Thoroughly inspecting the finished products for any defects, dimensional accuracy, and compliance with customer requirements.

- Quality Control System: Implementing a robust quality control system to identify and rectify potential issues promptly.

5. What are the common troubleshooting techniques used in foam rubber molding?

Troubleshooting techniques commonly used in foam rubber molding include:

- Identifying Foam Defects: Analyzing the appearance and properties of the foam to determine the root cause of defects, such as voids, shrinkage, or uneven density.

- Adjusting Process Parameters: Modifying molding parameters, such as temperature, pressure, or mixing time, to optimize foam formation and eliminate defects.

- Mold Maintenance: Regularly inspecting and maintaining molds to ensure proper operation and prevent contamination.

- Raw Material Analysis: Checking incoming raw materials for any deviations in quality or consistency that may impact foam properties.

- Foam Testing: Conducting additional tests on foam samples to confirm the effectiveness of troubleshooting measures.

6. How do you optimize the production efficiency of a foam rubber molding operation?

Optimizing production efficiency in foam rubber molding involves:

- Process Automation: Automating certain steps of the molding process, such as mixing and mold loading, to reduce labor costs and increase consistency.

- Mold Design Optimization: Using efficient mold designs that minimize cycle times and maximize foam quality.

- Improved Material Handling: Streamlining the flow of raw materials and finished products to minimize downtime and improve overall throughput.

- Proper Equipment Maintenance: Regularly servicing and calibrating equipment to ensure optimal performance and prevent breakdowns.

- Employee Training: Providing comprehensive training to operators to enhance their skills and improve productivity.

7. Explain the safety precautions that must be taken when working with foam rubber molding materials.

Safety precautions are essential when working with foam rubber molding materials:

- Proper Ventilation: Ensuring adequate ventilation in the work area to prevent exposure to harmful fumes and dust.

- Personal Protective Equipment (PPE): Wearing appropriate PPE, including gloves, safety glasses, and respirators, to protect against skin, eye, and respiratory irritation.

- Handling Chemicals Safely: Following proper handling and storage procedures for chemicals used in the molding process, such as foaming agents and catalysts.

- Machine Safety: Operating machinery, such as mixers and molds, in accordance with safety guidelines to prevent accidents.

- Emergency Procedures: Familiarizing oneself with emergency procedures and evacuation routes in case of accidents or incidents.

8. How do you stay updated with the latest advancements in foam rubber molding technology?

To stay updated with the latest advancements in foam rubber molding technology:

- Attend Industry Events: Participating in conferences and exhibitions to learn about new materials, equipment, and techniques.

- Read Trade Publications and Journals: Subscribing to industry-specific publications to access technical articles and research updates.

- Network with Professionals: Connecting with experts in the field through professional organizations and social media.

- Research and Development: Actively exploring new technologies and materials through research and collaboration with suppliers and research institutions.

9. Can you elaborate on your experience in troubleshooting foam rubber molding defects?

In my previous role at [Company Name], I encountered several foam rubber molding defects and implemented effective troubleshooting strategies:

- Voids and Shrinkage: Adjusted the foaming agent concentration and molding temperature to optimize foam expansion and reduce voids.

- Uneven Density: Identified variations in raw material quality and implemented stricter material control measures.

- Surface Roughness: Improved mold maintenance procedures and implemented a mold release agent to enhance surface finish.

- Cracking: Modified the curing time and temperature to optimize the cross-linking process and prevent premature cracking.

10. Describe your approach to quality control in foam rubber molding.

My approach to quality control in foam rubber molding encompasses:

- Incoming Material Inspection: Verifying the quality of incoming raw materials against specifications.

- In-Process Monitoring: Regularly monitoring molding parameters to ensure adherence to established standards.

- Foam Testing: Conducting regular tests on foam samples to assess density, hardness, and other properties.

- Finished Product Inspection: Thoroughly inspecting finished products for defects and dimensional accuracy.

- Corrective Action Implementation: Promptly addressing any quality issues identified through testing or inspections.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foam Rubber Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foam Rubber Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foam Rubber Molders play a crucial role in the production of foam rubber products, utilizing their expertise and skill to shape and form foam rubber materials into various items. Their key responsibilities include:

1. Mold Preparation

Preparing and maintaining molds is essential for producing high-quality foam rubber products. Molders must:

- Clean and inspect molds to ensure they are in good condition and free from any defects.

- Apply mold release agents to prevent the foam rubber from sticking to the mold.

- Assemble molds correctly and securely to create the desired shape of the product.

2. Foam Rubber Handling

Foam Rubber Molders handle and manipulate foam rubber materials with precision:

- Measuring and cutting foam rubber to the required dimensions.

- Mixing and preparing foam rubber compounds according to specifications.

- Placing foam rubber into molds and shaping it using various techniques.

3. Molding and Curing

Molders are responsible for the molding and curing processes that give foam rubber products their final form and properties:

- Operating molding machines to inject or pour foam rubber into molds.

- Monitoring and controlling molding conditions, such as temperature and pressure, to ensure proper curing.

- Ensuring that molded products meet specifications and quality standards.

4. Post-Molding Operations

After molding, Foam Rubber Molders may perform additional tasks to complete the production process:

- Trimming or cutting molded products to remove excess material.

- Inspecting finished products to ensure they meet customer requirements.

- Packaging and labeling foam rubber products for shipment.

Interview Tips

Preparing for an interview as a Foam Rubber Molder requires both technical knowledge and an understanding of the industry. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the company you are applying to and the foam rubber industry as a whole. Learn about their products, processes, and reputation. This will allow you to ask informed questions and demonstrate your interest in the field.

2. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the job. Quantify your accomplishments whenever possible, using specific examples to showcase your abilities in mold preparation, foam rubber handling, molding, and post-molding operations.

3. Be Prepared to Discuss Technical Details

Be prepared to answer questions about the technical aspects of foam rubber molding. This may include discussing mold design, material properties, and curing processes. You should also be able to explain your understanding of quality control and safety procedures.

4. Showcase Your Problem-Solving Abilities

Foam Rubber Molders often encounter challenges in their work. During the interview, be prepared to share examples of how you have solved problems or overcome obstacles in previous roles.

5. Prepare Questions for the Interviewer

Preparing questions for the interviewer demonstrates your interest in the position and the company. Ask questions about the company’s growth plans, their commitment to quality, and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Foam Rubber Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!