Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Foam Tank Laminator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Foam Tank Laminator so you can tailor your answers to impress potential employers.

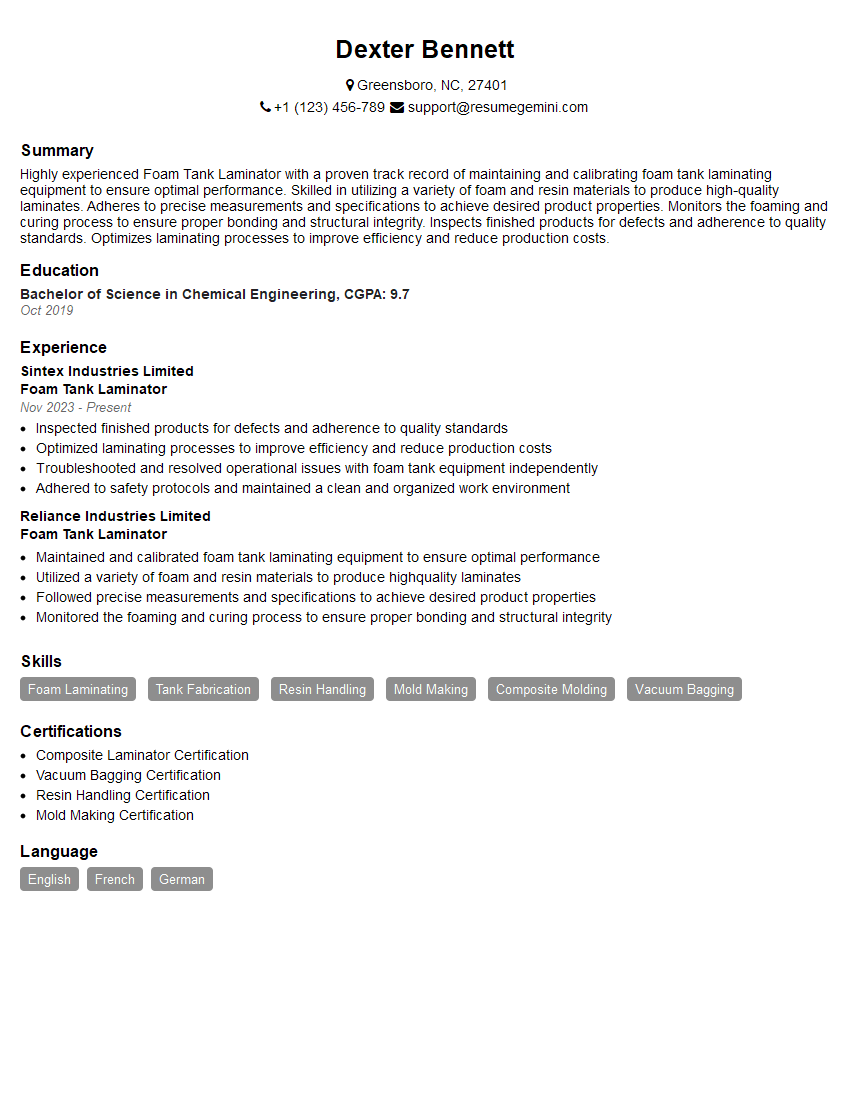

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foam Tank Laminator

1. Explain the process of foam tank lamination?

- Prepare the foam and laminate materials.

- Apply adhesive to the foam.

- Position the laminate over the foam.

- Press the laminate into the foam.

- Cure the adhesive.

2. What are the different types of foam that can be used for lamination?

Polyurethane foam

- Rigid

- Flexible

Polyethylene foam

- Cross-linked

- Non-cross-linked

3. What are the different types of laminates that can be used for lamination?

- Paper-based laminates

- Plastic-based laminates

- Metal-based laminates

4. What are the benefits of using foam tank lamination?

- Increased strength and durability

- Improved appearance

- Reduced noise and vibration

5. What are the challenges of foam tank lamination?

- The process can be time-consuming.

- The materials can be expensive.

- The process requires specialized equipment.

6. What are the quality control measures that should be used for foam tank lamination?

- Visual inspection

- Destructive testing

- Non-destructive testing

7. What are the safety precautions that should be taken when working with foam tank lamination?

- Wear appropriate personal protective equipment.

- Use the equipment properly.

- Follow the manufacturer’s instructions.

8. What are the maintenance procedures that should be followed for foam tank lamination equipment?

- Clean the equipment regularly.

- Lubricate the equipment regularly.

- Inspect the equipment regularly.

9. What are the troubleshooting tips for foam tank lamination?

- If the laminate is not adhering to the foam, the adhesive may not be applied properly.

- If the laminate is bubbling, the adhesive may not be cured properly.

- If the laminate is tearing, the foam may be too thin.

10. What are the future trends in foam tank lamination?

- The use of new materials, such as graphene and carbon fiber.

- The development of new processes, such as vacuum lamination and ultrasonic lamination.

- The increased use of automation in the lamination process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foam Tank Laminator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foam Tank Laminator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Foam Tank Laminators are responsible for creating and maintaining composite structures used in various industries. Their key responsibilities include:

1. Foam Tank Operation

Preparing and operating foam tanks to produce composite structures.

- Calculating material quantities and mixing ratios.

- Loading and unloading foam into the tank.

2. Laminating Process

Laminating foam cores and reinforcing materials to create composite structures.

- Applying resins and adhesives to surfaces.

- Laying up and bonding laminates according to specifications.

3. Quality Control

Ensuring the quality of composite structures through inspections and testing.

- Inspecting laminates for defects and flaws.

- Performing destructive and non-destructive tests to evaluate structural integrity.

4. Equipment Maintenance

Maintaining and cleaning foam tanks and related equipment.

- Troubleshooting and repairing equipment malfunctions.

- Adhering to safety regulations and procedures.

Interview Tips

To ace the interview for a Foam Tank Laminator position, candidates should:

1. Research the Company and Role

Thoroughly research the company and the specific role to understand their products, services, and industry. This knowledge will allow you to tailor your answers and demonstrate your interest in the position.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the latest trends.

2. Highlight Relevant Skills and Experience

Emphasize your skills in foam tank operation, laminating, quality control, and equipment maintenance. Provide specific examples of your work and demonstrate your proficiency in these areas.

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your responsibilities and achievements.

3. Show Enthusiasm and Attention to Detail

Convey your passion for working with composites and your commitment to producing high-quality products. Highlight your attention to detail and your ability to work independently and as part of a team.

- Share examples of projects where you went above and beyond to meet specifications.

- Explain how your work contributes to the overall success of the team.

4. Prepare for Technical Questions

Be prepared to answer questions about foam tank operation, laminating techniques, and quality control procedures. Review relevant industry standards and demonstrate your understanding of the technical aspects of the role.

- Practice answering common interview questions related to your field.

- Bring a portfolio or examples of your work to showcase your skills.

Next Step:

Now that you’re armed with the knowledge of Foam Tank Laminator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Foam Tank Laminator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini